Humidity-regulating controlled-release type gas phase corrosion inhibitor

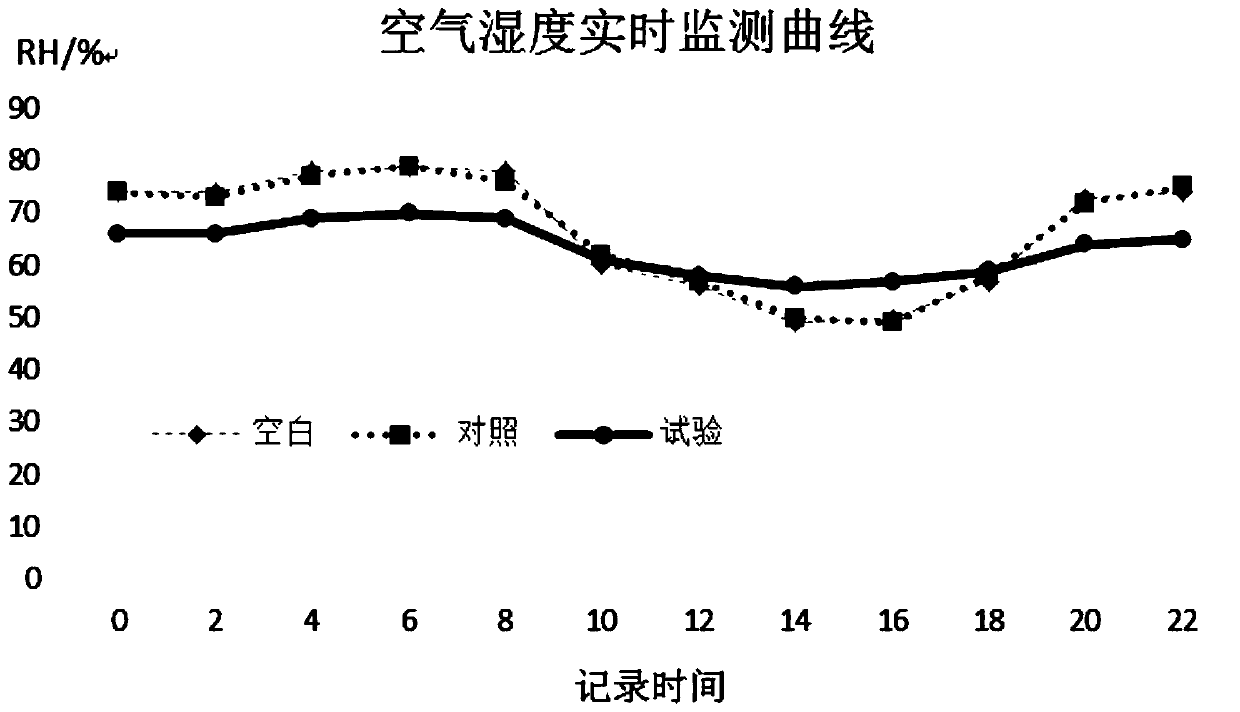

A gas-phase corrosion inhibitor and humidity control technology, which is applied in the field of metal corrosion and protection, can solve the problems of environmental humidity control, VCI loss, long anti-rust period, etc., and achieve the effect of wide application range, convenient use and long anti-rust period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

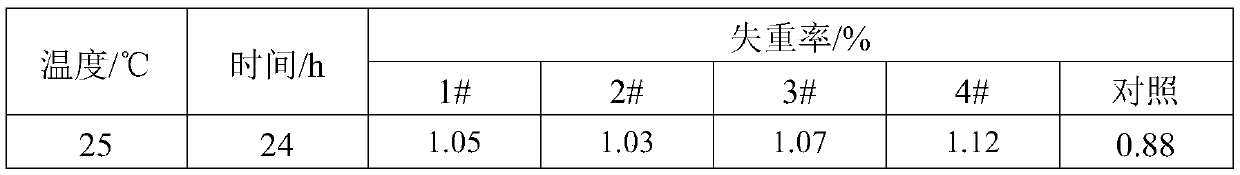

Examples

Embodiment 1

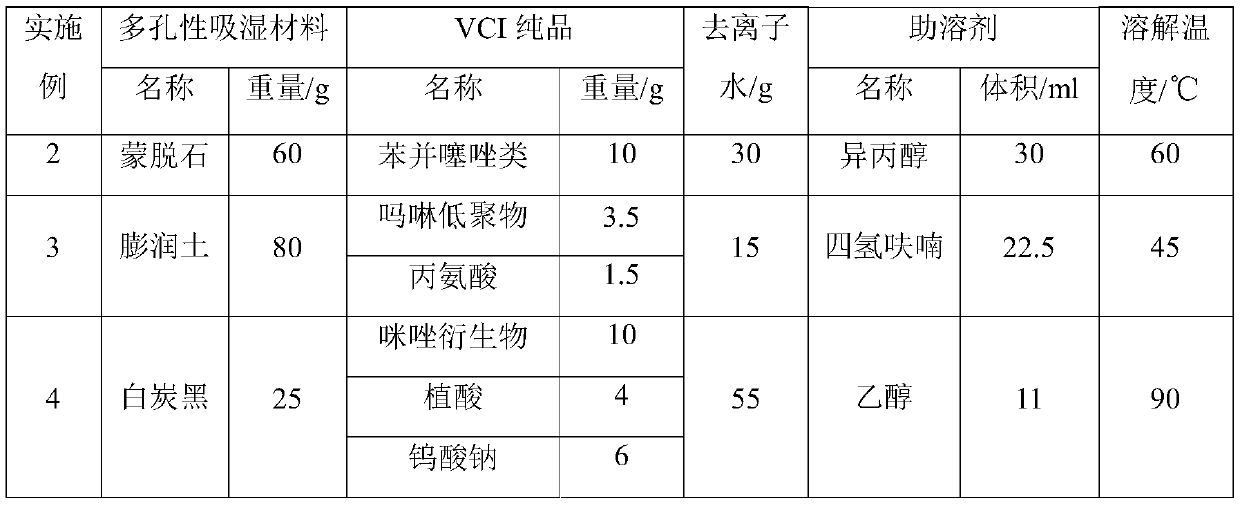

[0033] A humidity-adjusting and controlled-release gas-phase corrosion inhibitor, which consists of 20%-80% by mass of porous hygroscopic material, 5%-20% by mass of pure gas-phase corrosion inhibitor and 10-60% by mass of deionized water.

[0034] Wherein, the porous hygroscopic material is one of silica gel powder, bentonite, montmorillonite, zeolite, and white carbon black. These porous supports have a rich pore structure with an extremely large surface area for the adsorption of water molecules. There is an equilibrium relationship between the moisture content of the carrier and the humidity of the environment. According to this equilibrium relationship, these carriers can be used to adjust the humidity in the environment. Porous hygroscopic materials not only have well-developed pores and a large specific surface area, but also have many hydroxyl groups on the surface, which can be adsorbed together with the functional groups of the gas phase corrosion inhibitor by hydro...

specific example 1

[0037] Specific example 1: the mass percentage of each component is: porous hygroscopic material 70%, gas phase corrosion inhibitor pure product 10%, deionized water 20%.

specific example 2

[0038] Specific example 2: the mass percentage of each component is: porous hygroscopic material 50%, gas phase corrosion inhibitor pure product 15%, deionized water 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com