Crude oil demulsifier and preparation method thereof

A crude oil demulsifier and demulsifier technology, applied in the direction of chemical dehydration/demulsification, etc., can solve problems such as poor demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

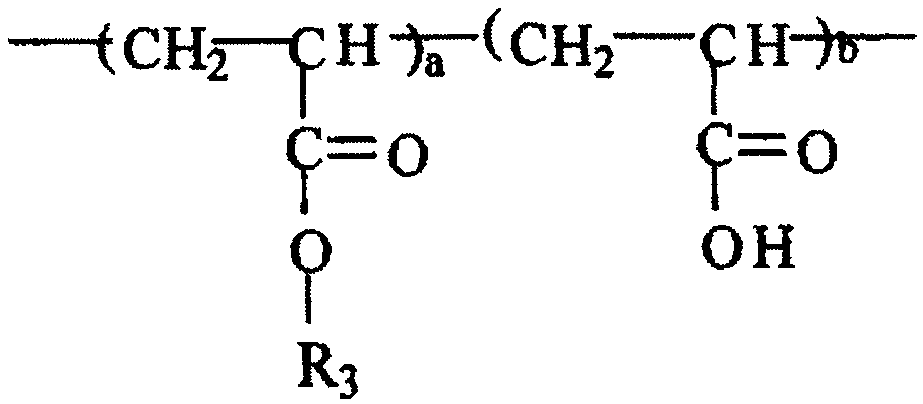

Image

Examples

preparation example Construction

[0063] In the preparation method of the present invention, the solvent used will be suitable for the solution polymerization reaction of the present invention, and can be selected arbitrarily within the scope of not affecting the demulsifier of the present invention. For example, the solvent is aromatic hydrocarbons, alcohols, Ketone or ester organic solvents, such as benzene, xylene, etc.

[0064] The polymerization reaction of the present invention is preferably carried out at 50-90°C.

[0065] Preferably, the amount of acrylic acid monomer added in the initial stage of the polymerization reaction is 20%-50% of the total amount of acrylic acid, and the remaining acrylic acid monomer can be added continuously dropwise or in batches, and the number of batch additions is 2-6 times , more preferably 3 times. The time intervals of adding acrylic acid monomers can be equal or different, and can be selected according to the needs of the polymerization reaction process.

[0066] I...

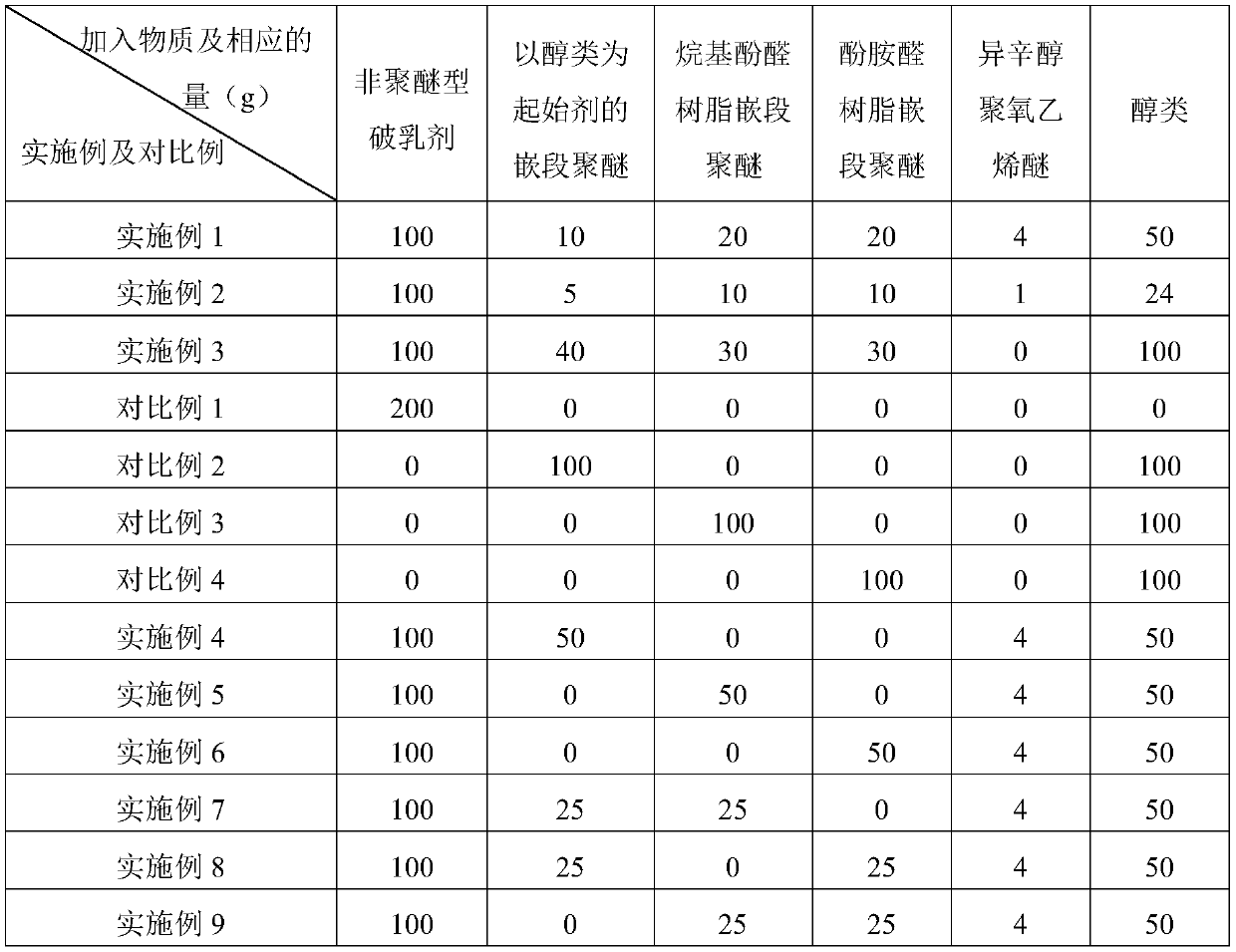

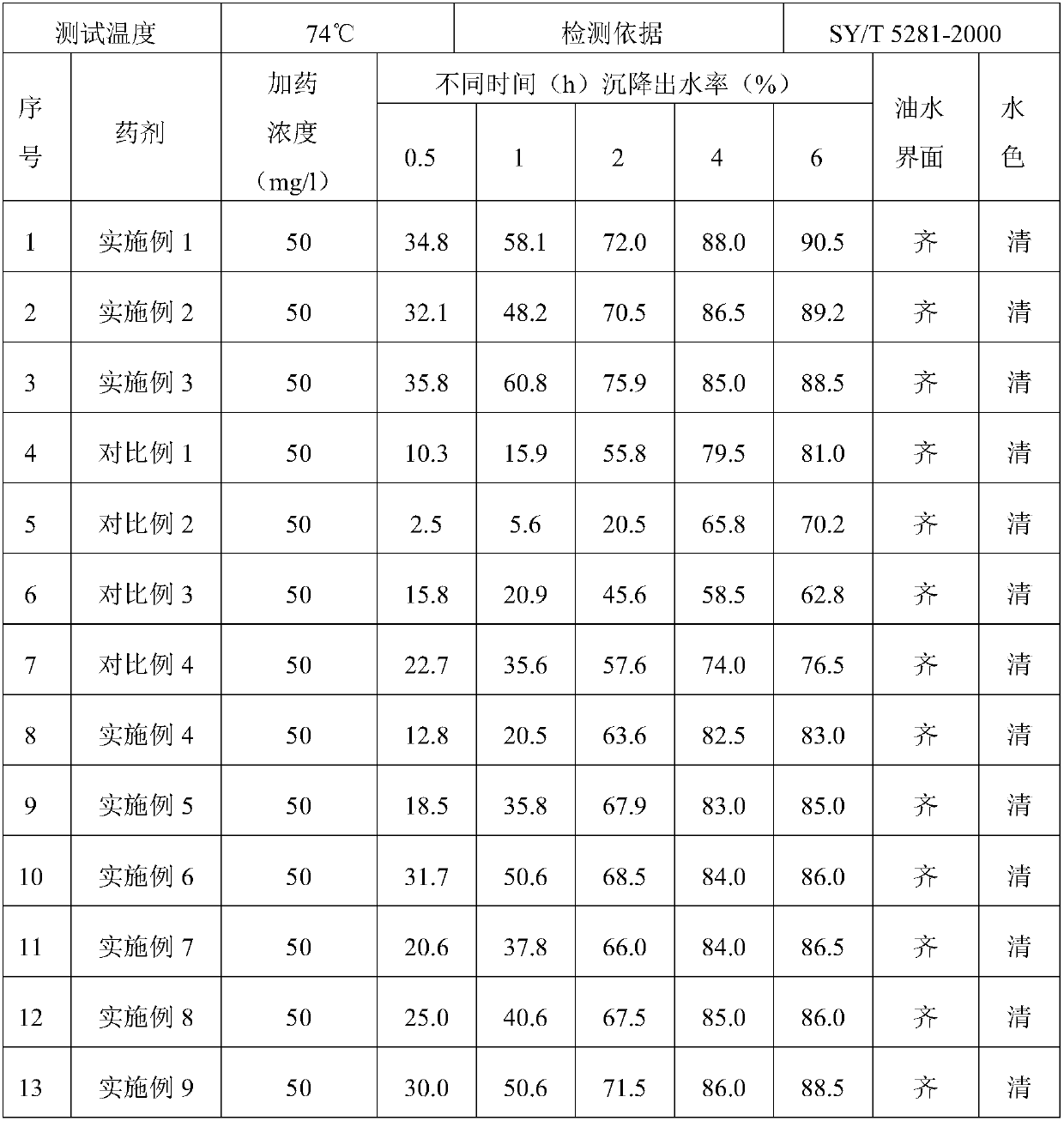

Embodiment 1

[0091] Add 10g of block polyether BPE2040 starting with alcohol, 310-520g of alkyl phenolic resin block polyether and 20g of phenolic aldehyde resin block polyether dry agent DPA2031 into the reaction kettle in proportion, and keep stirring 4g of n-dodecyl alcohol and 46g of methanol were added thereto, and the temperature of the kettle was raised to 60°C. After stirring for 30 minutes, 100g of non-polyether demulsifier solution and 4g of isooctyl alcohol polyoxyethylene ether OE35 were added to the mixture. After stirring for 30 minutes, stop heating, stir while cooling, and cool to normal temperature to obtain a low-temperature demulsifier.

Embodiment 2

[0093] Add 5g of block polyether BPE2040, 10g of alkyl phenolic resin block polyether 3105 and 10g of phenolic aldehyde resin block polyether dry agent DPA2031 10g with alcohols as the initiator, into the reaction kettle in proportion, and continuously Under stirring, add 4g of n-octanol and 20g of methanol, raise the temperature of the kettle to 60°C, continue stirring for 30min, add 100g of non-polyether demulsifier solution and 1g of isooctyl alcohol polyoxyethylene ether OE35 to the mixture, After stirring for 30 minutes, stop heating, stir while cooling, and cool to normal temperature to obtain a low-temperature demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com