Aluminum wood veneer

A veneer and aluminum-wood technology, applied in the field of aluminum-wood veneer, can solve the problems of poor sound insulation and thermal insulation performance of wood veneer, high installation cost of wood veneer, large degree of deformation of wood veneer, etc., to improve the overall structural strength , good decorative effect, the effect of enhancing the decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

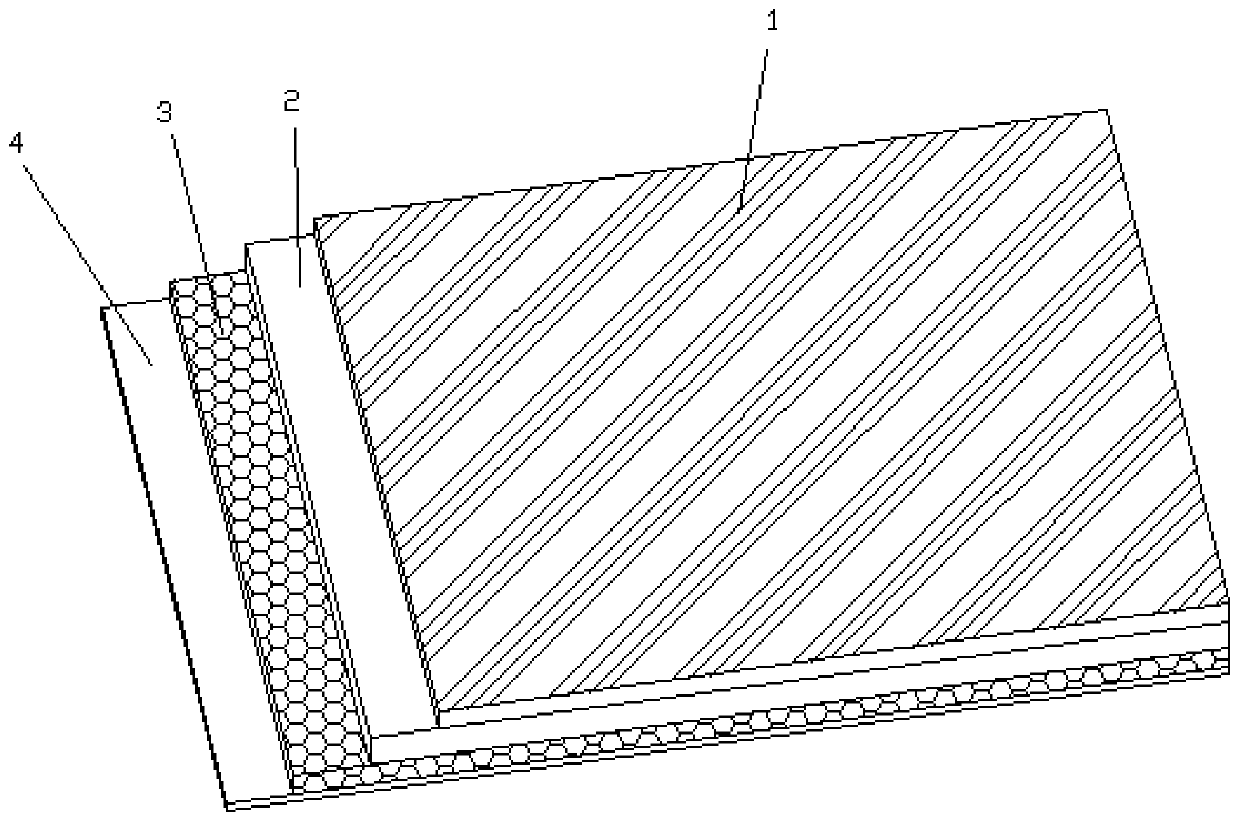

[0021] Referring to the accompanying drawings, an aluminum-wood veneer of the present invention includes a surface decoration layer 1, a base material layer 2, a support layer 3 and a backing layer 4, and the upper surface of the base material layer 2 is provided with a surface decoration layer 1, The lower surface of the base material layer 2 is provided with a supporting layer 3, the lower surface of the supporting layer 3 is provided with a backing layer 4, and the surface decoration layer 1, the base material layer 2, the supporting layer 3 and the backing Layers 4 are bonded with glue and compacted by a flat press.

[0022] Wherein, the surface decoration layer 1 can be any one of technical wood veneer layer, stone material decoration layer or cloth decoration layer, and the thickness of the surface decoration layer 1 is 0.6-1.0mm.

[0023] Wherein, the surface of the technical veneer layer is coated with wear-resistant paint, and the wear-resistant paint is an environmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com