Method for preparing aniline through nitrobenzene hydrogenation and preparation method for catalyst used in method

A technology for the preparation of nitrobenzene and hydrogen, which is applied in the preparation of organic compounds, molecular sieve catalysts, and amino compounds. It can solve problems such as difficult continuous production, easy corrosion of equipment, and difficult product separation, achieving high selectivity and low price. Inexpensive, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

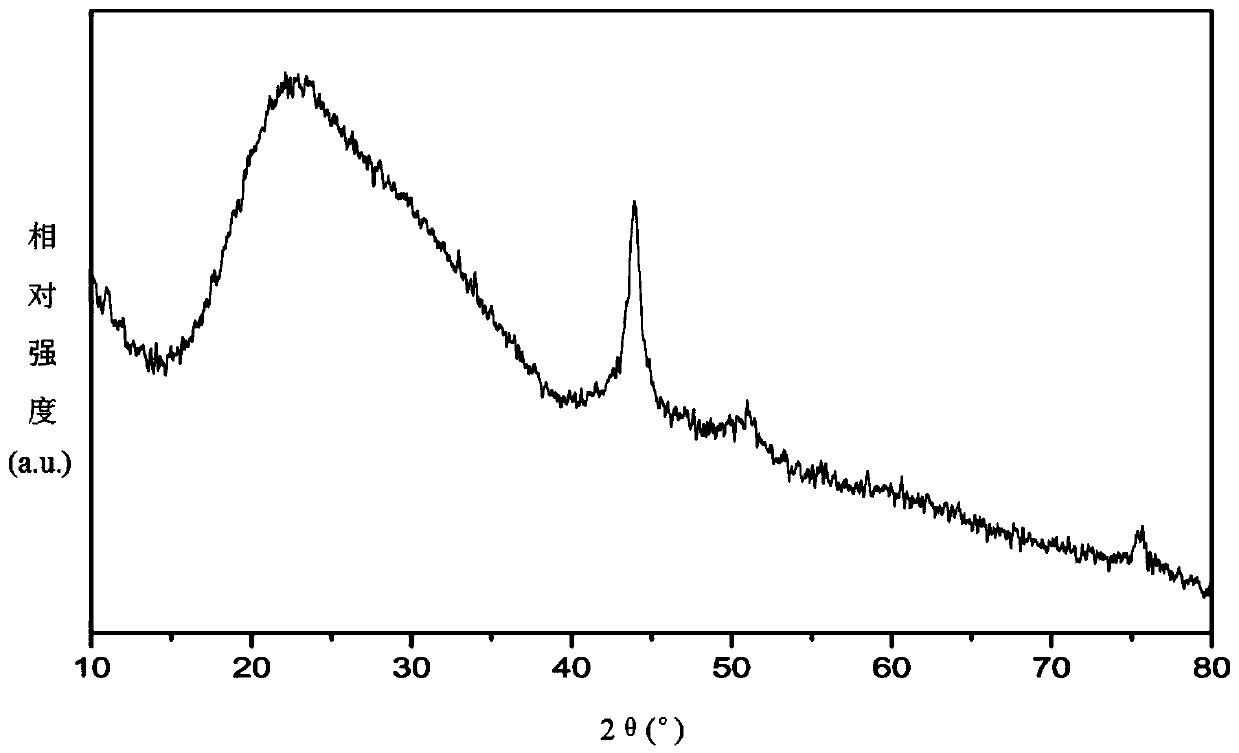

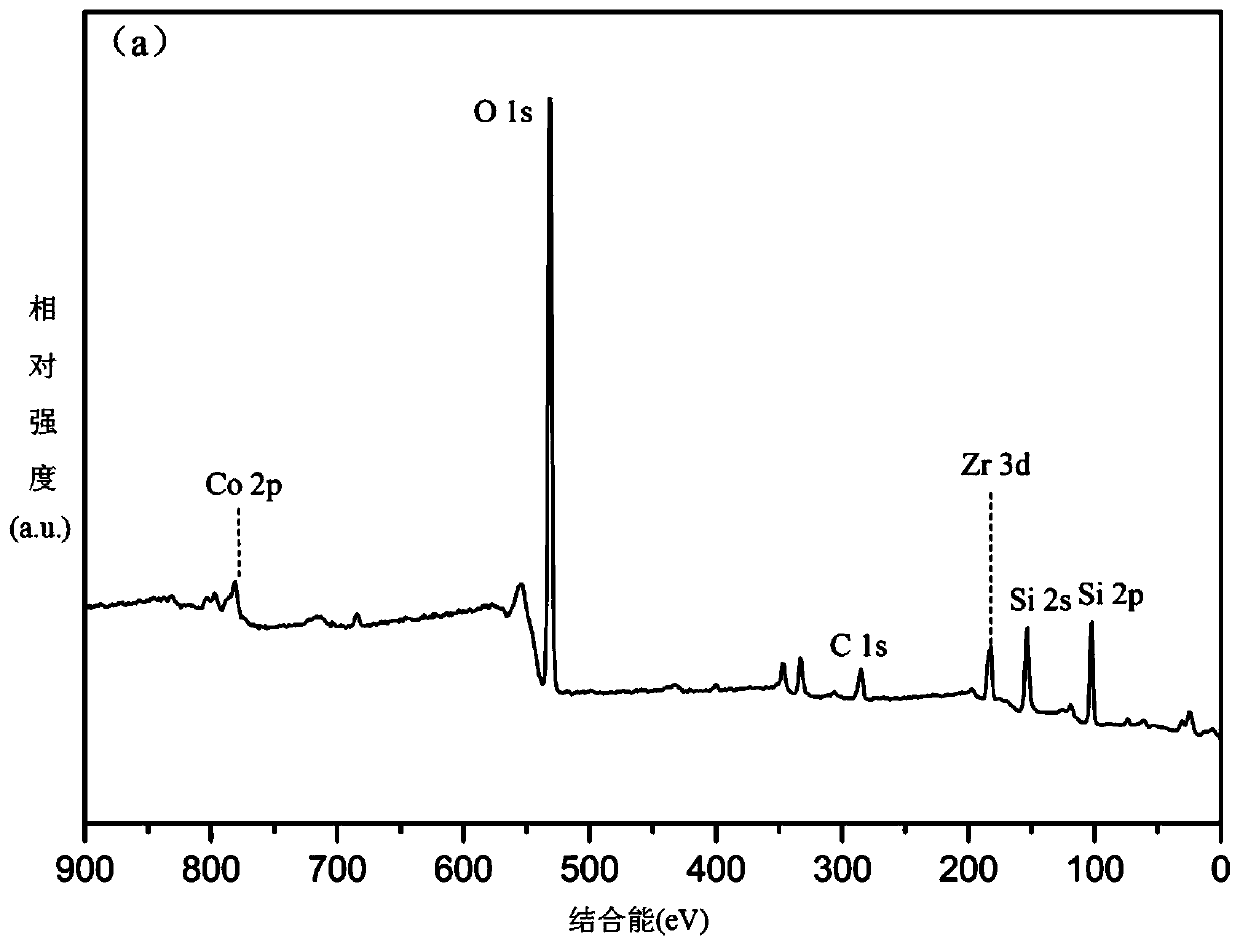

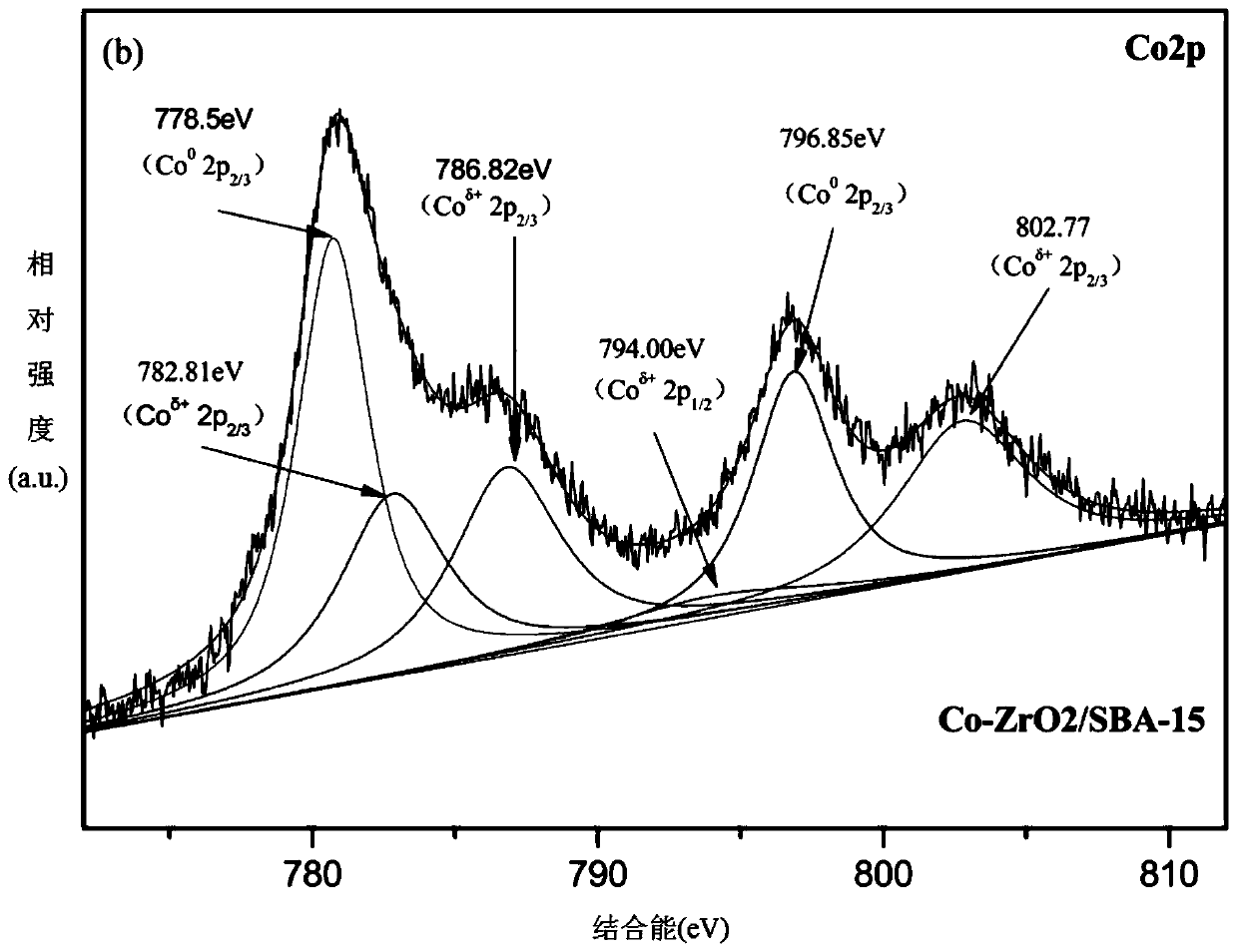

[0023] Catalyst preparation: take 0.146g ZrOCl 2 ·8H 2 O was dissolved in 15mL deionized water and ultrasonicated for 10min to make ZrOCl 2 ·8H 2 O is completely dissolved, add 0.5g SBA-15, heat in a water bath at 80°C and stir for 4h, then use 0.2mol / L NH 4 HCO 3 The pH of the solution was adjusted to 9, continued to stir for 5 hours, and stood still for 12 hours. The resulting solution was washed with deionized water, filtered, dried at 80°C, and calcined at 600°C to obtain a zirconia / SBA-15 composite carrier with a mass fraction of zirconia of 10%. Take 0.5g zirconia / SBA-15 and dissolve in ethylene glycol, then add 0.276g Co(NO 3 ) 2 ·6H 2 O, stirred in a water bath at 30°C for 6h, with 0.2mol / LNH 3 ·H 2 O adjusted the pH to 9, continued to stir for 4 h, washed the resulting solution three times with absolute ethanol and deionized water, dried in vacuum at 80 °C, and reduced with hydrogen at 600 °C for 4 h to obtain a Co-zirconia / zirconia with a mass fraction of 10%...

Embodiment 2

[0026] Same as Example 1, except that the mass fraction of Co in Co-zirconia / SBA-15 is 5%, that is, 5% Co-10% zirconia / SBA-15.

Embodiment 3

[0028] Same as Example 1, the difference is that the mass fraction of Co in Co-zirconia / SBA-15 is 15%, that is, 15% Co-10% zirconia / SBA-15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com