Water-gas separator

A technology of water-gas separator and separator, applied in the direction of separation method, liquid degassing, chemical instrument and method, etc., can solve the problem of CO concentration exceeding the standard, and achieve the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

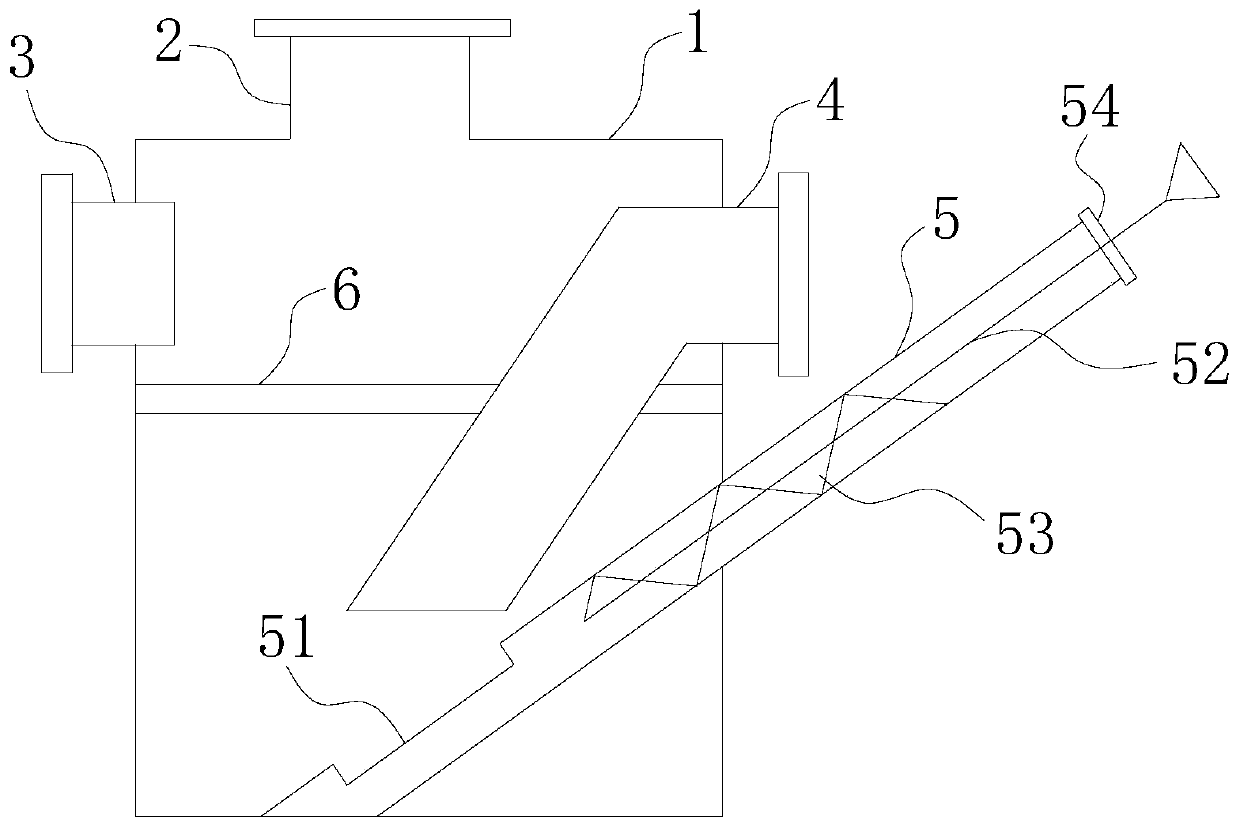

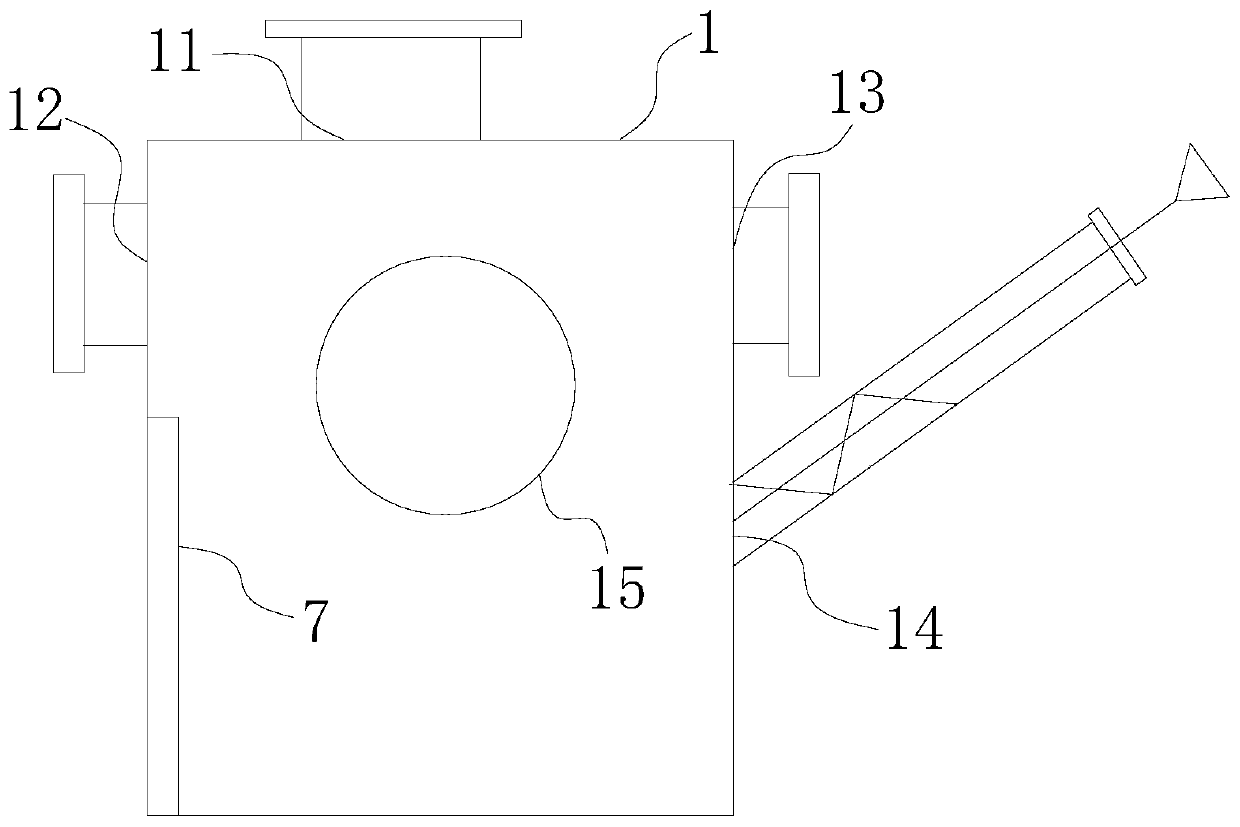

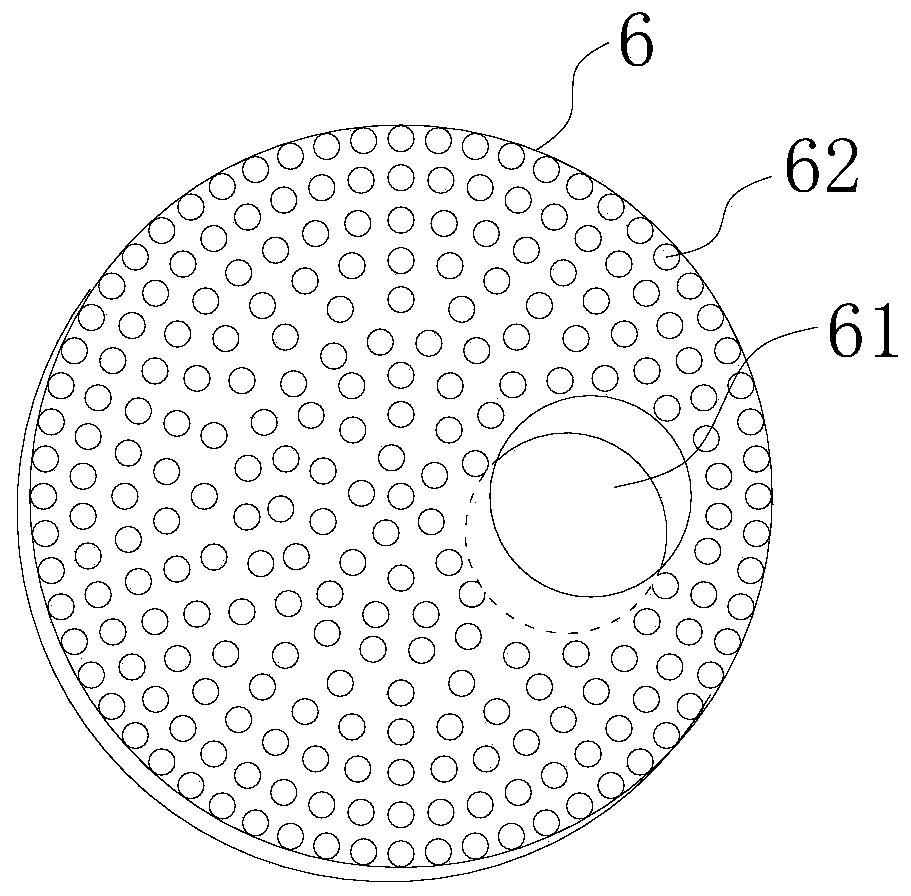

[0017] like Figure 1-3 As shown, a water-gas separator includes a housing 1, the top of the housing 1 is provided with an exhaust port 11, and the exhaust port 11 is provided with an exhaust pipe 2, and the separated gas is exhausted The pipe 2 is connected to the flue for centralized treatment. One side of the housing 1 is provided with a water inlet 12, and the other side is provided with a water outlet 13 and a slag discharge outlet 14, and the water inlet 12 and the water outlet 13 are at the same height. The slag discharge port 14 is located below the water outlet 13. The water inlet 12 and the water outlet 13 are respectively provided with a water inlet pipe 3 and a water outlet pipe 4. The water outlet pipe 4 extends to the lower end of the housing 1 and is inclined downward. Set to prevent the gas from leaking directly into the sedimentation tank when the water level of the separator is low. The slag discharge port 14 is provided with a slag discharge pipe 5 for distu...

Embodiment 2

[0019] Based on the structure of Embodiment 1, in Embodiment 2, an observation hole 15 is provided on the housing 1 to facilitate observation of the sedimentation condition of the separator.

Embodiment 3

[0021] Based on the structure of Embodiment 1, in Embodiment 3, an online CO detector is provided at the water outlet 13, which can monitor the CO concentration of the water in the outlet pipe 4 in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com