Portable alternating-current and direct-current arc welding generator

A generator, AC and DC technology, applied in the field of electric welding machines, can solve the problems of inability to use electric welding machines for construction operations, and achieve the effects of small impedance, small inductance and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A portable AC / DC arc welding generator of the present invention will be described in detail below with reference to the accompanying drawings.

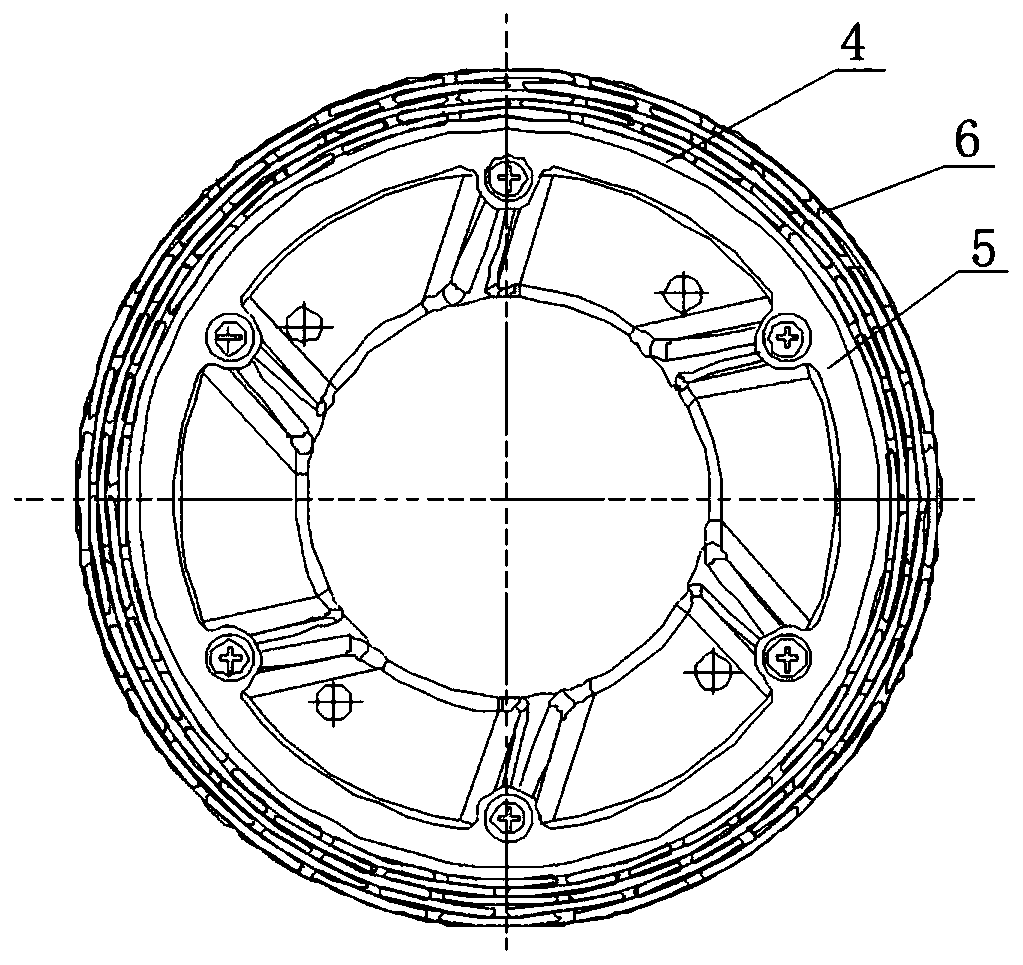

[0019] Including an internal combustion engine, a generator and a bridge rectifier. The generator is composed of a stator and a rotor. The stator is arranged in the middle of the rotor to form an outer rotor generator. The stator is composed of a stator core 4 and a stator winding 6. The outer circle of the stator core 4 There is a rectangular groove 7 on the upper axis, and the stator winding 6 is snake-shaped and layered and embedded in the rectangular groove 7 on the outer circle of the stator core 4. The diameter of the enameled wire of the stator winding 6 matches the width of the rectangular groove 7. Each layer of the enameled wire of the stator winding 6 forms an independent circuit, and the stator windings 6 of the independent circuits are connected in parallel to the AC input end of the bridge rectifier 9 , and the DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com