Fault positioning method and system for spliced image floor defect detection

A defect detection and fault location technology, applied in the field of defect detection, can solve problems such as difficult positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

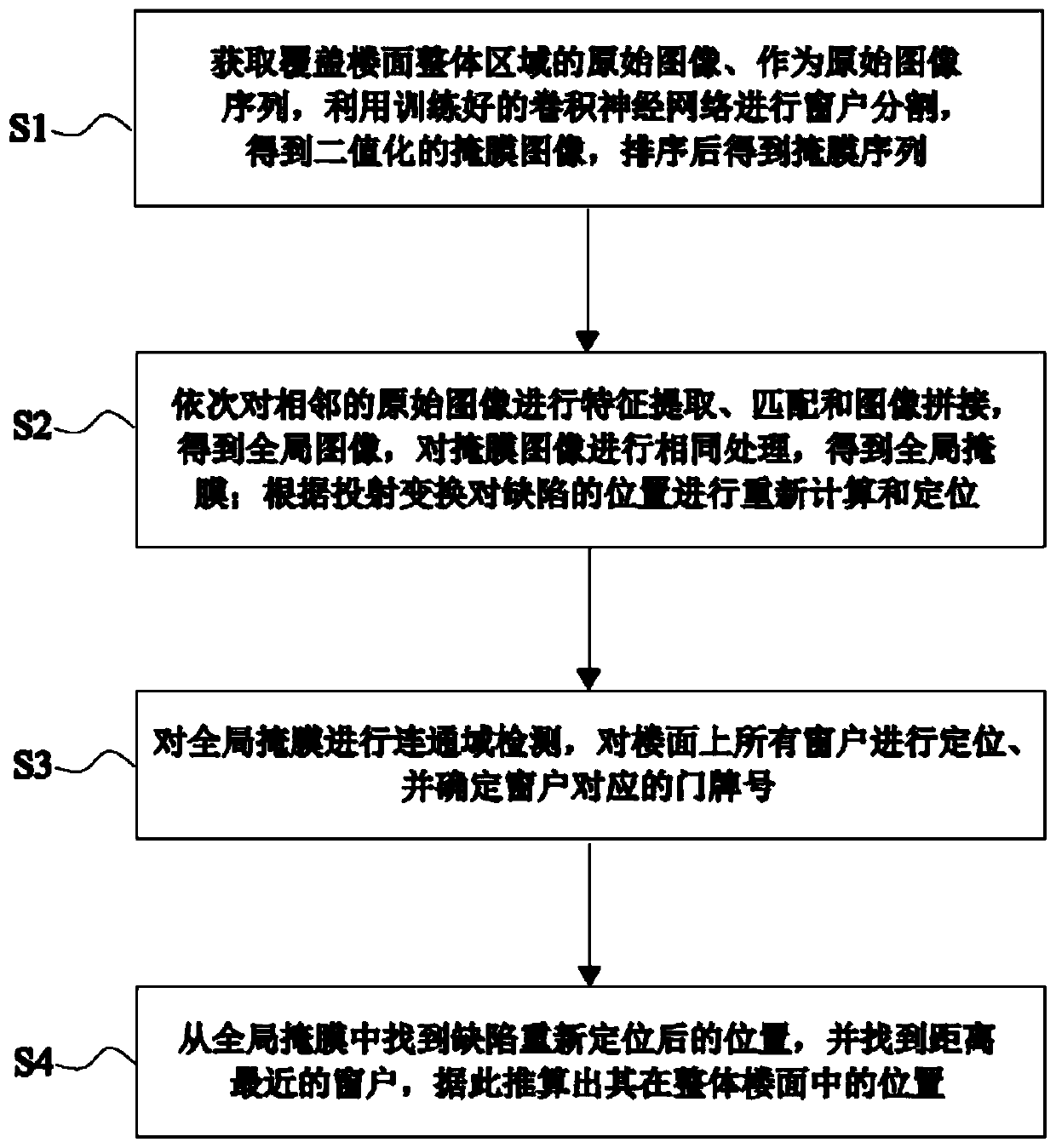

[0071] Such as figure 1 As shown, this embodiment 1 provides a fault location method for splicing image floor defect detection, including the following steps:

[0072] S1: Window segmentation: First, use the trained Mask RCNN to segment the windows in each original image I in the original image sequence to obtain a binarized mask image I with the same size as the original image mask , where 0 represents a window, and 255 represents a non-window; according to the original image sequence {I mask} in the order of each original image, sort the mask images, and get the mask sequence

[0073] S2: Image stitching: Since the two adjacent photos are also adjacent in spatial position when shooting, all the original images in the original image sequence are searched for feature points and stitched to obtain the global image G, and the mask sequence All mask images of the same splicing process are performed to obtain the global mask G mask , and at the same time relocate the defect pos...

Embodiment 2

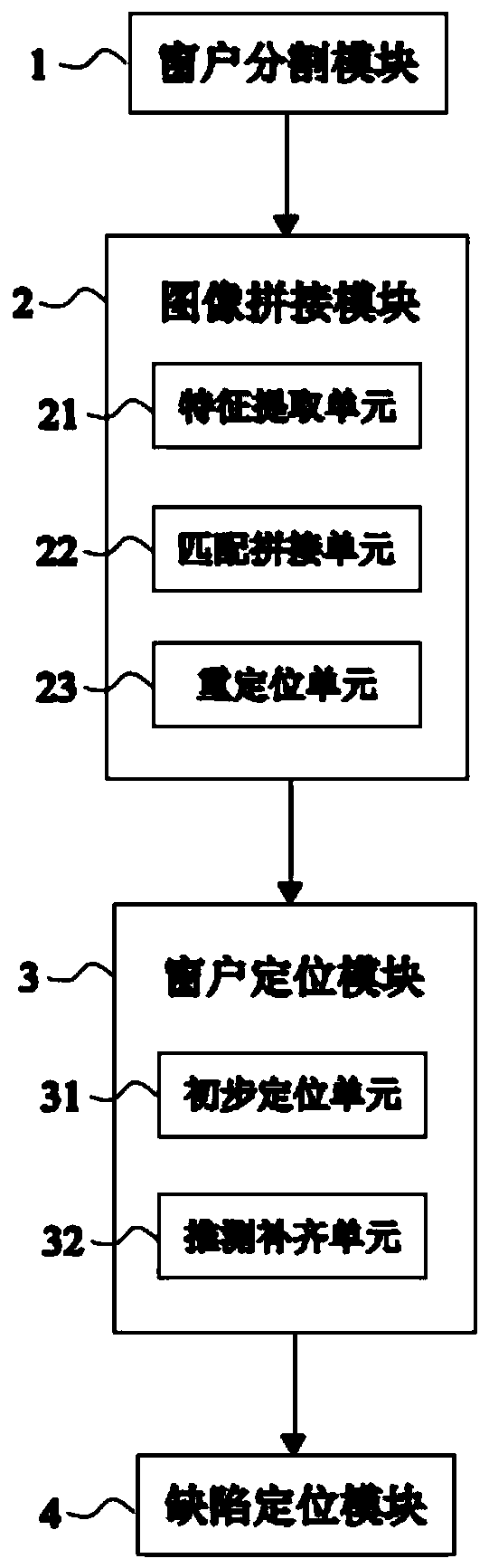

[0101] Such as figure 2 As shown, this embodiment 2 provides a fault location system for fault detection of spliced image floor defect detection by running the method provided by embodiment 1, including a window segmentation module 1, an image splicing module 2, a window positioning module 3 and a defect location module connected in sequence. Positioning module 4, the window division module 1 is configured to:

[0102] Obtain a series of original images covering the entire area of the floor as an original image sequence, use the trained convolutional neural network to segment the windows in each original image, and obtain a binarized mask with the same size as the original image image, and sort all the mask images to get the mask sequence;

[0103] Image stitching module 2 is configured as:

[0104] Perform feature extraction, matching and image stitching on adjacent original images in turn to obtain a global image; use the same method to perform feature extraction, mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com