Effluent collecting device capable of applying back pressure

A collection device and supply device technology, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of difficulty in ensuring saturation effect, inability to achieve back pressure loading, inability to achieve back pressure application, etc. Solving the effect of insufficient soil saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

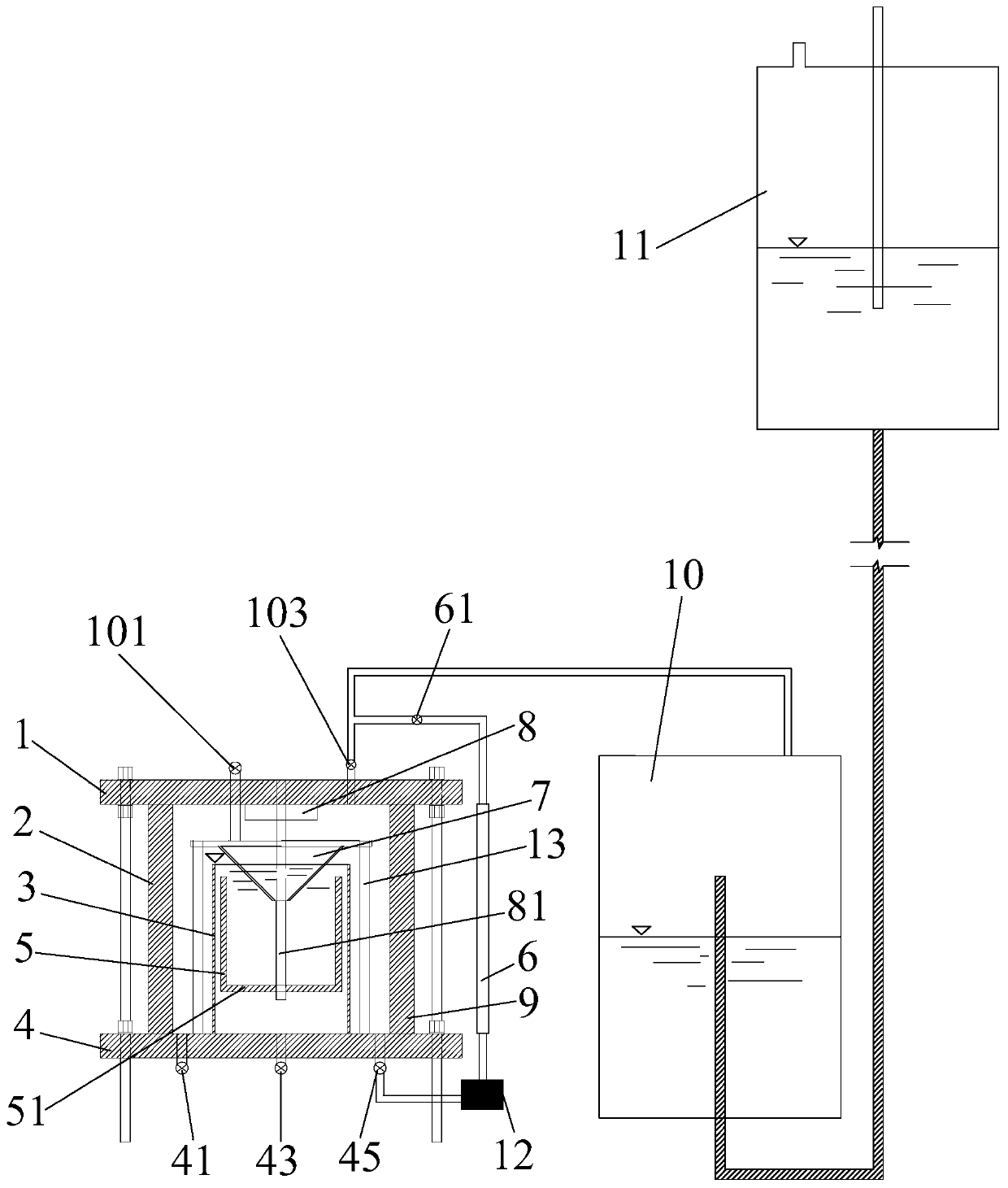

[0038] Specific embodiment: an outflow collection device that can realize back pressure loading, including a cavity, a pressure sensor, a differential pressure sensor, a funnel, an inner cylinder, an outer cylinder, a tray, a filter screen, a reference tube and an air pressure supply device, the cavity The top plate of the cavity is provided with an outflow liquid infiltration port and a vent hole, and the bottom plate of the cavity is provided with a side drain port, a water inlet port and a communication hole. The pressure sensor is fixed on the end face of the chamber top plate facing the interior of the chamber by bolts, and a screw rod is installed at the bottom of the pressure sensor. The funnel is set in the cavity through a bracket, and a hole is opened on the top of the funnel to allow the screw rod installed at the bottom of the pressure sensor to pass through. There are threaded holes, and the tray is connected to the screw rod on the bottom of the pressure sensor t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Side wall height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com