Anti-rust oil free of heavy metals

A technology for anti-rust oil and heavy metals, applied in the petroleum industry, fatty acid production, fatty acid esterification, etc., can solve the problem of difficult degradation, and achieve the effect of prolonging the anti-rust time, saving non-renewable energy and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

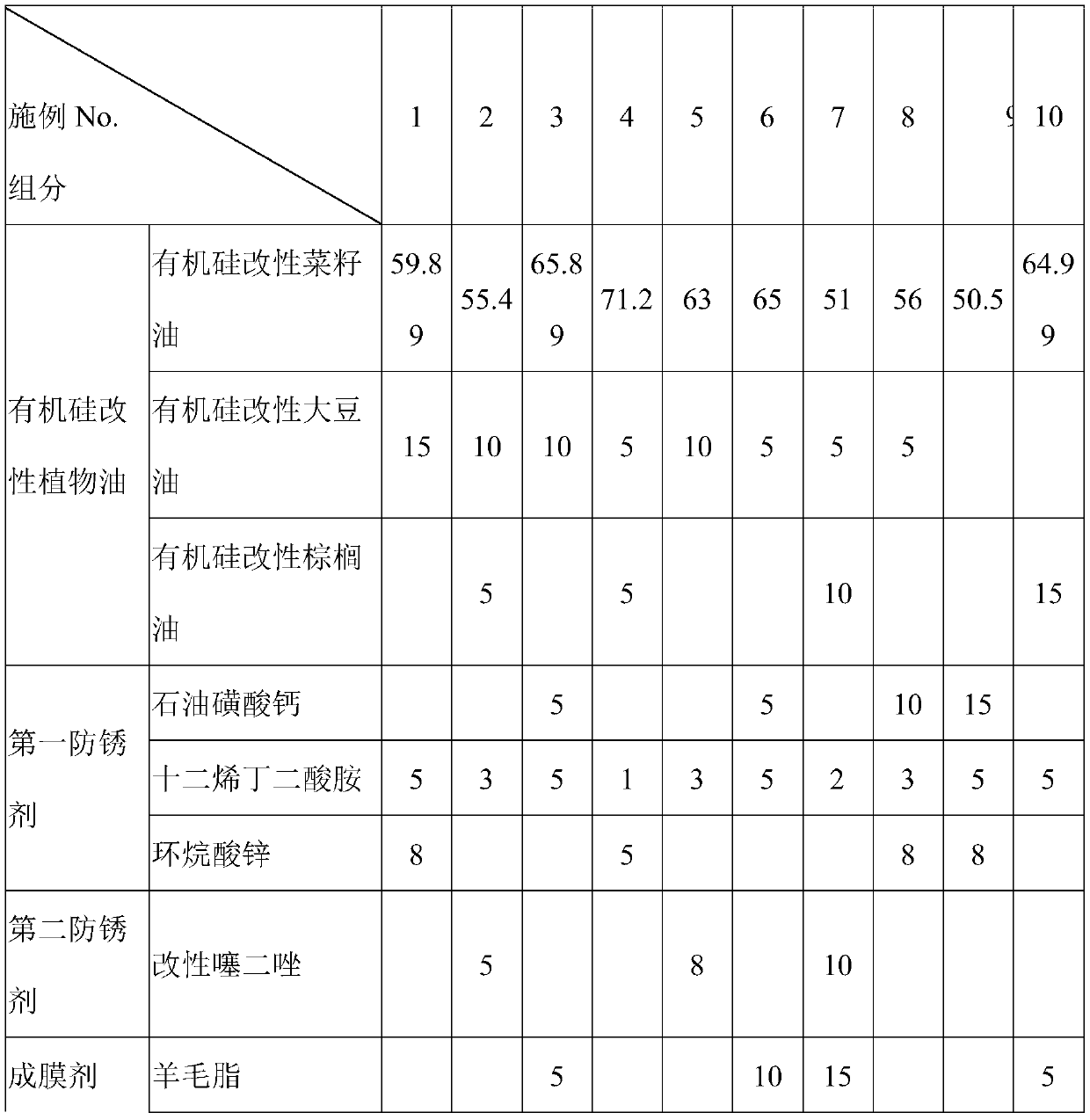

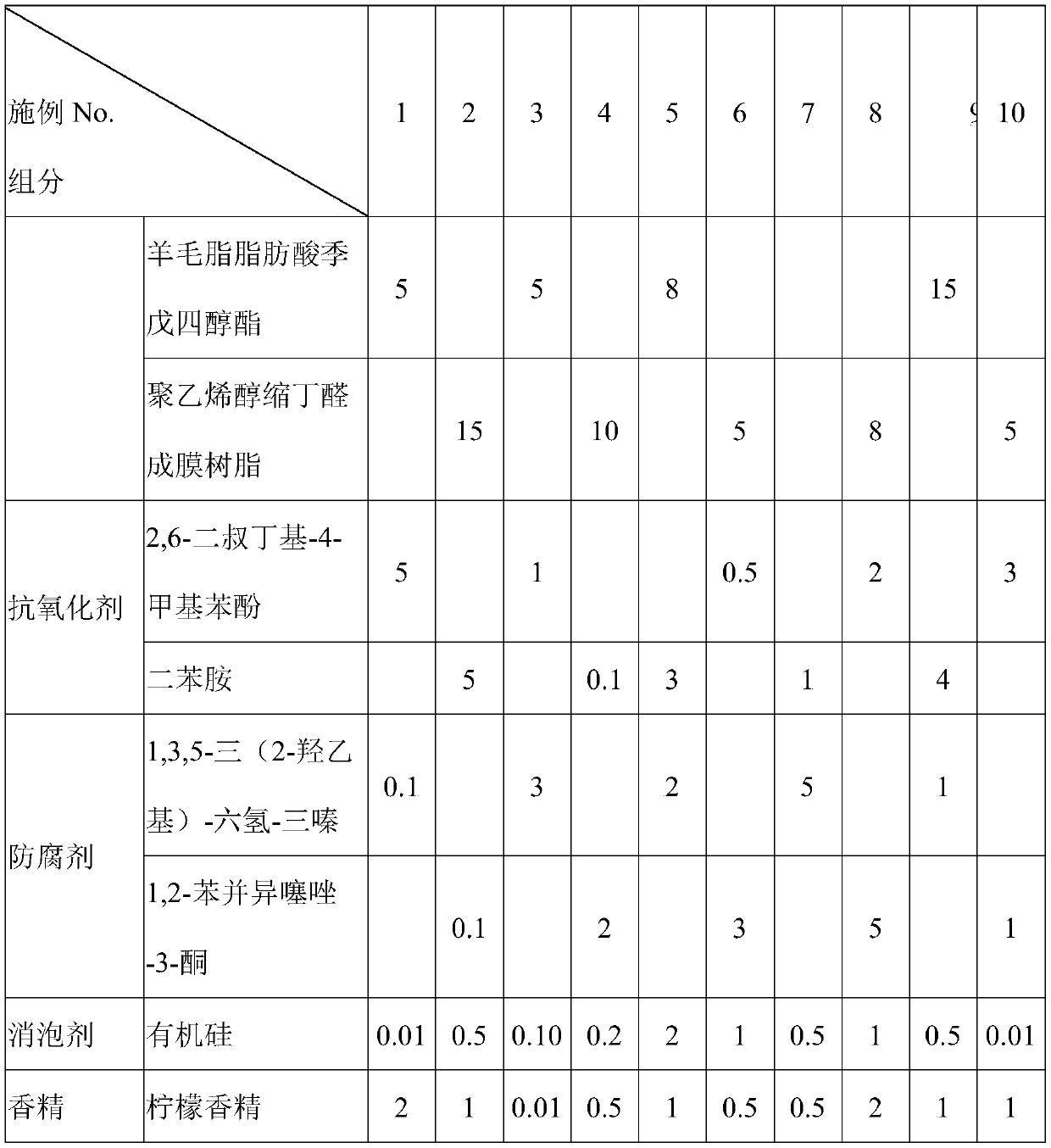

[0052] The present invention provides a heavy metal-free rust preventive oil, which comprises the components according to the weight percentages of Example 1 in Table 1 above.

[0053] 1. Preparation of organosilicon-modified vegetable oil

[0054] The preparation method of organosilicon modified vegetable oil comprises the steps:

[0055] (1) Add 100 parts of vegetable oil by mass into the reactor, then gradually add 25 parts of potassium hydroxide methanol solution with a mass concentration of 8%, then carry out transesterification at a temperature of 70° C. for 2 h, wash to Neutral, dehydrated and dried to obtain fatty acid methyl esters;

[0056] (2) Add the mixture of 120 parts of acetic acid and the strong acidic cation exchange resin catalyst to 100 mass fractions of fatty acid methyl esters obtained in the step (1) at a temperature of 60°C, then gradually add hydrogen peroxide solution, wherein H O and acetic acid The mol ratio is 1.2:1, insulation 4h carries out epo...

Embodiment 2-10

[0069] Each of the antirust oils without heavy metals in Examples 2-10 includes the components in the weight percent of Examples 2-10 in the above table 1, and the preparation method of the organosilicon-modified vegetable oil used, the modified thiadiazole The preparation method and the preparation method of the heavy metal-free antirust oil are consistent with Example 1.

[0070] The methods, procedures, and evaluations of the physical properties of the heavy metal-free rust preventive oils of Examples 1-10 were carried out in accordance with standards such as GB / T510, SH / T0215, and GB / T2361. The results are shown in Table 2.

[0071] The physical properties and antirust performance evaluation results of each heavy metal-free antirust oil of table 2 embodiment 1-10

[0072]

[0073] The heavy metal-free antirust oil prepared according to the different formulations of Examples 1-10 has good physical properties and antirust performance, especially the antirust performance; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com