A surfactant composition is provided

A technology of surfactant and composition, applied in the field of surfactant composition, can solve the problems of difficult selection of oil displacement system, high salinity of formation water, deep burial, etc., so as to improve oil recovery rate and temperature resistance. Effect of salt resistance, high displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

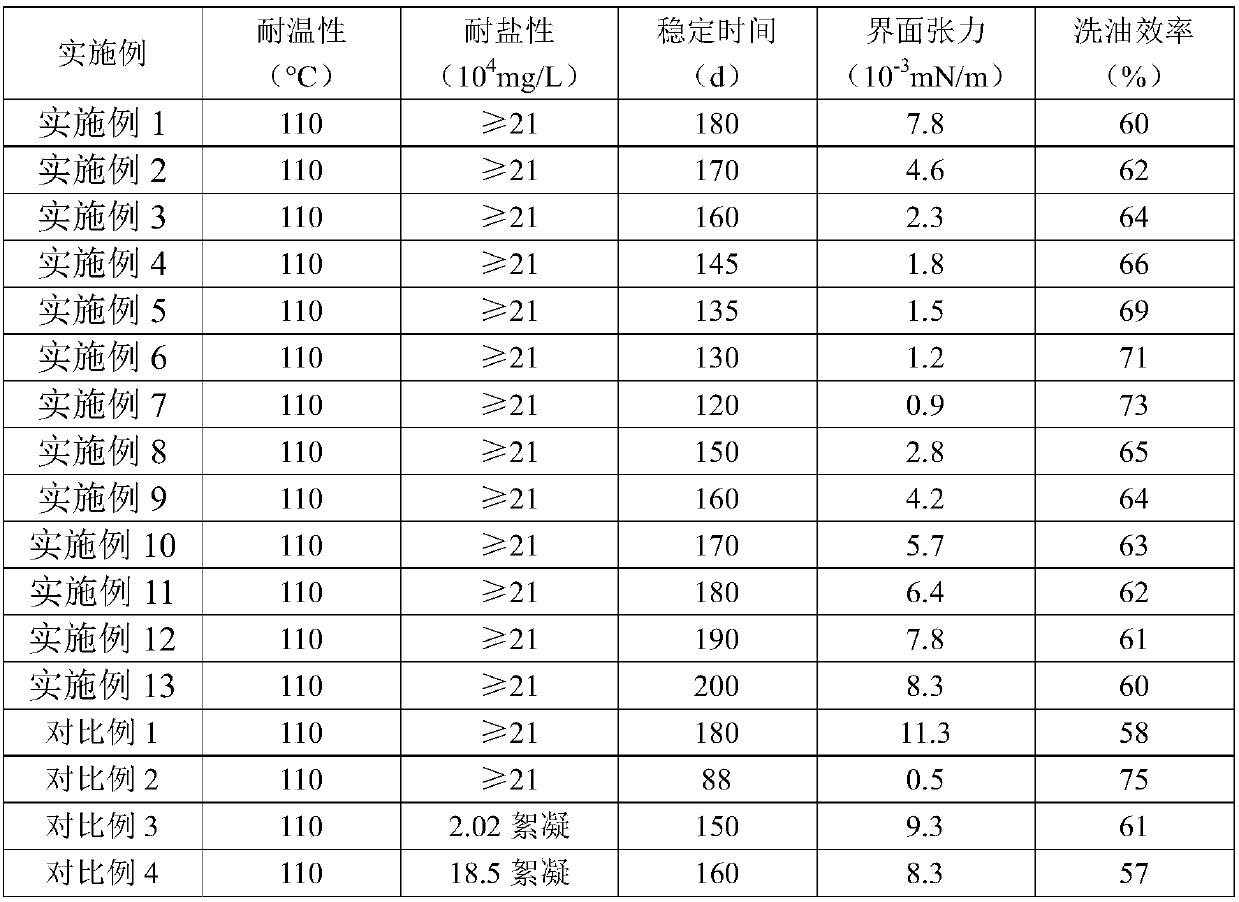

Examples

Embodiment 1

[0020] Will C 16 Sodium α-alkenyl sulfonate (purchased from Henan Weixi Trading Co., Ltd.), cetyl dimethyl betaine (purchased from Shanghai Shengxuan Biochemical Co., Ltd.), the degree of hydrolysis is 15%, and the relative molecular weight is 11 million Polyacrylamide (purchased from Zhengzhou Anlu Environmental Protection Equipment Co., Ltd.), stearylamide (purchased from Hubei Xinmingtai Chemical Co., Ltd.) was mixed in a mass ratio of 10:1:5:3 formulated, and then dissolved in a salinity of 2.24×10 5 ppm of formation water, forming a 0.3% surfactant aqueous solution.

Embodiment 2

[0022] Will C 18 Sodium α-alkenyl sulfonate (purchased from Henan Weixi Trading Co., Ltd.), dodecyl dimethyl betaine (purchased from Shanghai Shengxuan Biochemical Co., Ltd.), the degree of hydrolysis is 15%, and the relative molecular weight is 11 million Polyacrylamide (purchased from Zhengzhou Anlu Environmental Protection Equipment Co., Ltd.) and cetyl alcohol amide (purchased from Hubei Xinmingtai Chemical Co., Ltd.) were mixed according to the mass ratio of 10:1:5:3, and then dissolved in Salinity is 2.25×10 5 ppm of formation water, forming a 0.35% surfactant aqueous solution.

Embodiment 3

[0024] Will C 14 Sodium α-alkenyl sulfonate (purchased from Henan Weixi Trading Co., Ltd.), tetradecyl dimethyl betaine (purchased from Shanghai Shengxuan Biochemical Co., Ltd.), the degree of hydrolysis is 15%, and the relative molecular weight is 11 million Polyacrylamide (purchased from Zhengzhou Anlu Environmental Protection Equipment Co., Ltd.) and eicosanolamide (purchased from Hubei Xinmingtai Chemical Co., Ltd.) were mixed in a mass ratio of 10:1:5:3, and then dissolved in Salinity is 2.21×10 5 ppm of formation water, forming a 0.4% surfactant aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com