Ecologically-environment-friendly decorative plate and wet-method plate manufacturing process thereof

A decorative board and environmental protection technology, applied in the field of wet eco-friendly decorative boards and their wet-process board-making process, can solve the problems of affecting crop cultivation, polluting the environment, unable to rot quickly, etc., and achieve good social benefits, low cost, and easy quality control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An ecological and environment-friendly decorative board is made by using the following raw materials and production process in parts by weight: 300 fresh pineapple leaves; 30 composite adhesives; 0 antifungal agents; 2 adhesion promoters. Production process: fresh pineapple leaf straw crushing→extrusion dehydration→water washing and dehydration to extract fibers (moisture content not less than 15%)→quantitative adhesion promoter mix well→quantitative adhesive mix well→pave rough board→prepress rough board→ Rough board transportation → hot pressing → dehydration and health preservation → trimming and sanding → stacking and packaging of finished products. Main technical indicators: the pressure of the hot press forming is 3MPa; the heating temperature of the hot press forming is 30°C;

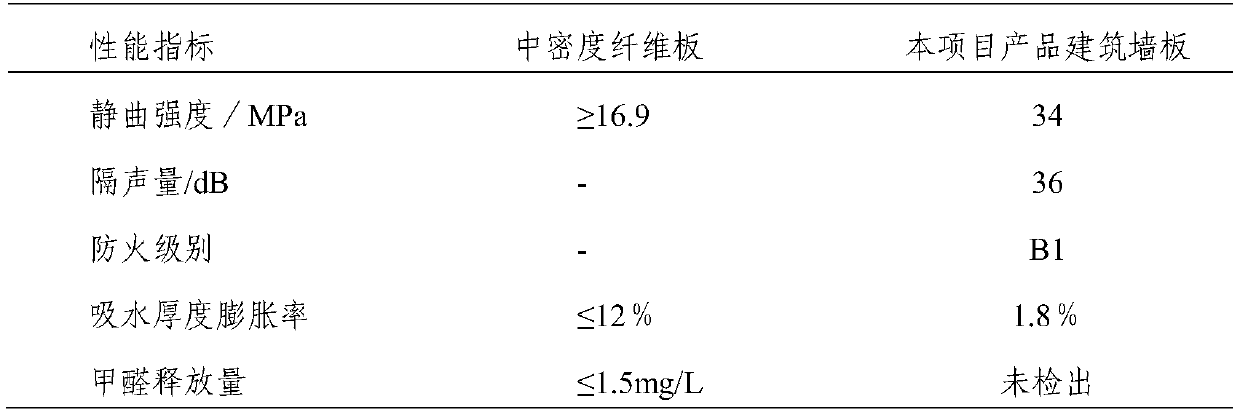

[0023] The performance index of the product is compared with the national first-class standard of MDF as follows:

[0024] Comparison of test results of various performance indicators of ...

Embodiment 2

[0027] An ecological and environment-friendly decorative board is made by using the following raw materials and production process in parts by weight: 900 parts by weight of fresh pineapple leaves; 300 parts by composite adhesive; 2 parts by weight of antifungal agent; Production process: fresh pineapple leaf straw crushing→extrusion dehydration→water washing and dehydration to extract fibers (moisture content not less than 15%)→quantitative adhesion promoter mix well→quantitative adhesive mix well→pave rough board→prepress rough board→ Rough board transportation → hot pressing → dehydration and health preservation → trimming and sanding → stacking and packaging of finished products. Main technological indicators: the pressure of the hot press forming is 200MPa; the heating temperature of the hot press forming is 220°C;

Embodiment 3

[0029] An ecological and environment-friendly decorative board is made by using the following raw materials and production process in parts by weight: 400 fresh pineapple leaves; 60 composite adhesives; 1 antifungal agent; 3.5 adhesion promoters. Production process: fresh pineapple leaf straw crushing→extrusion dehydration→water washing and dehydration to extract fibers (moisture content not less than 15%)→quantitative adhesion promoter mix well→quantitative adhesive mix well→pave rough board→prepress rough board→ Rough board transportation → hot pressing → dehydration and health preservation → trimming and sanding → stacking and packaging of finished products. Main process technical indicators: the pressure of the hot press forming is 100MPa; the heating temperature of the hot press forming is 120°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com