Tea seed continuous cycle cleaning technology for tea oil production and processing

A cleaning and tea seed technology, applied in solid separation, sieve, grid and other directions, can solve the problems of long time consumption, complicated operation, increase of operation steps, etc., and achieve the effect of improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

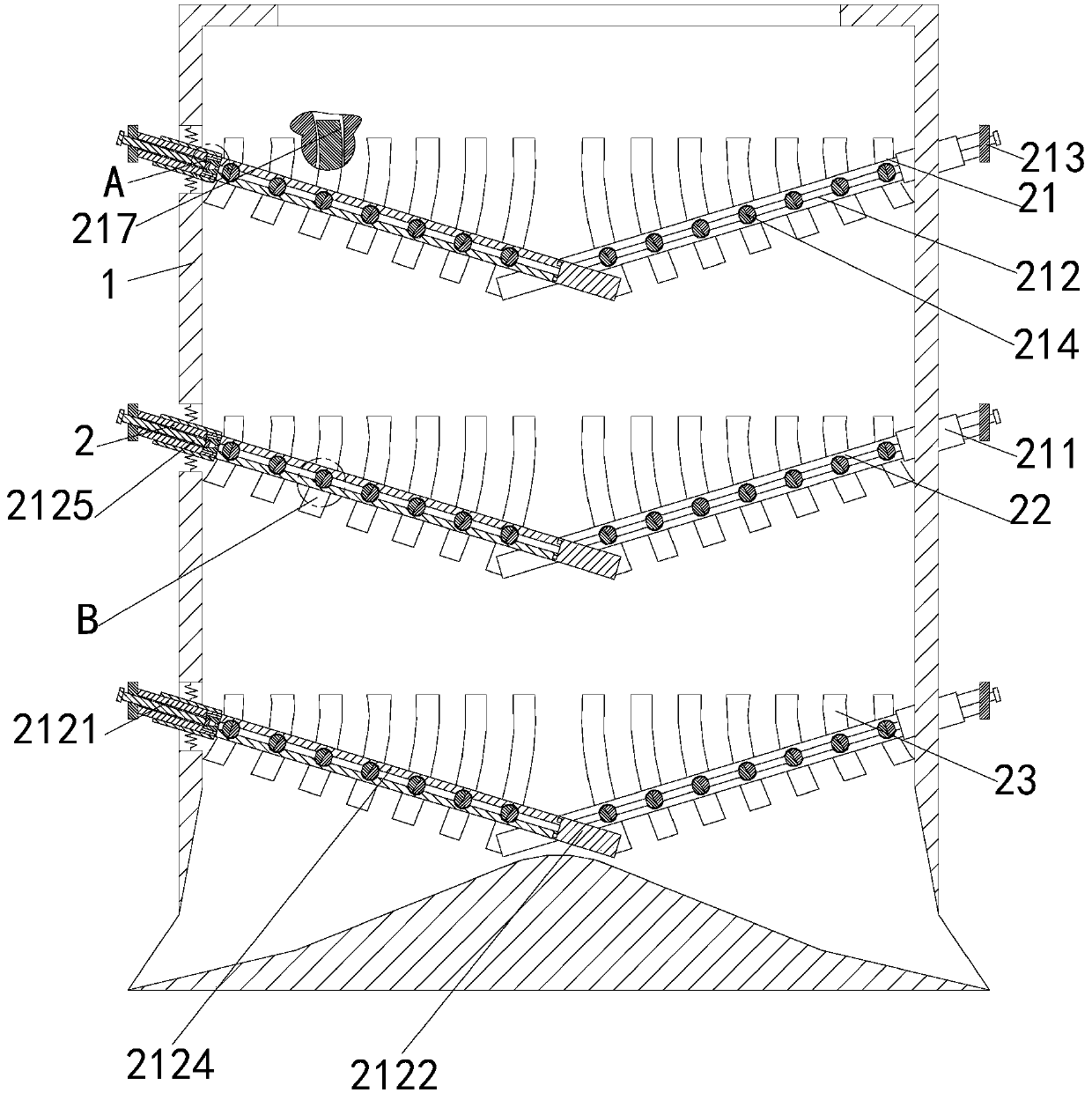

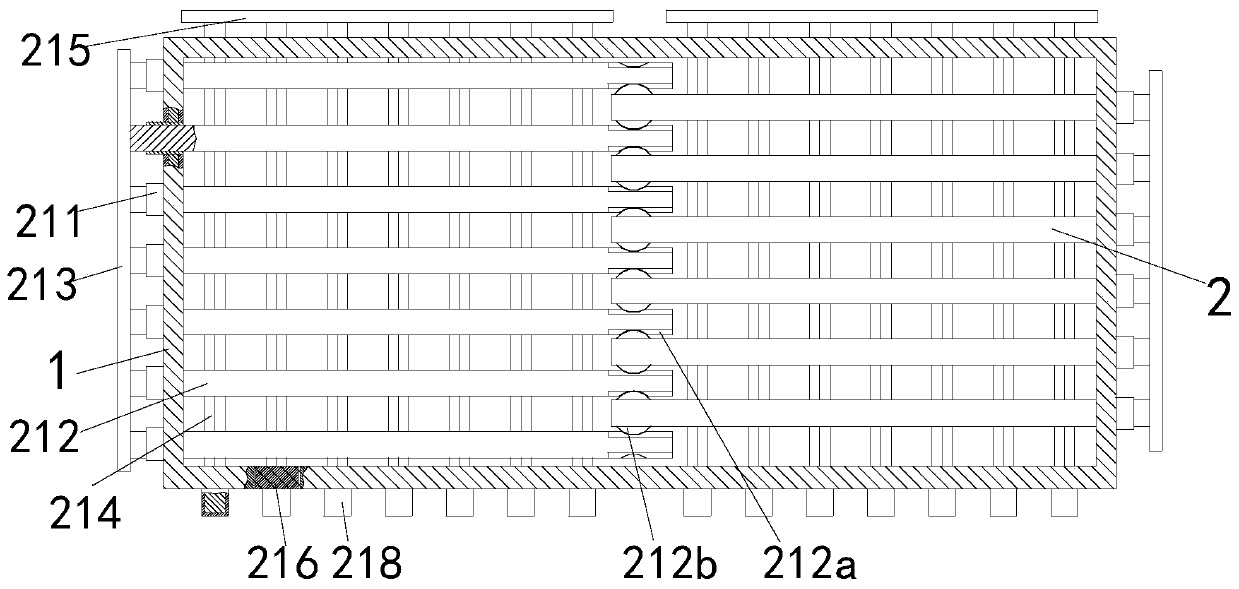

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

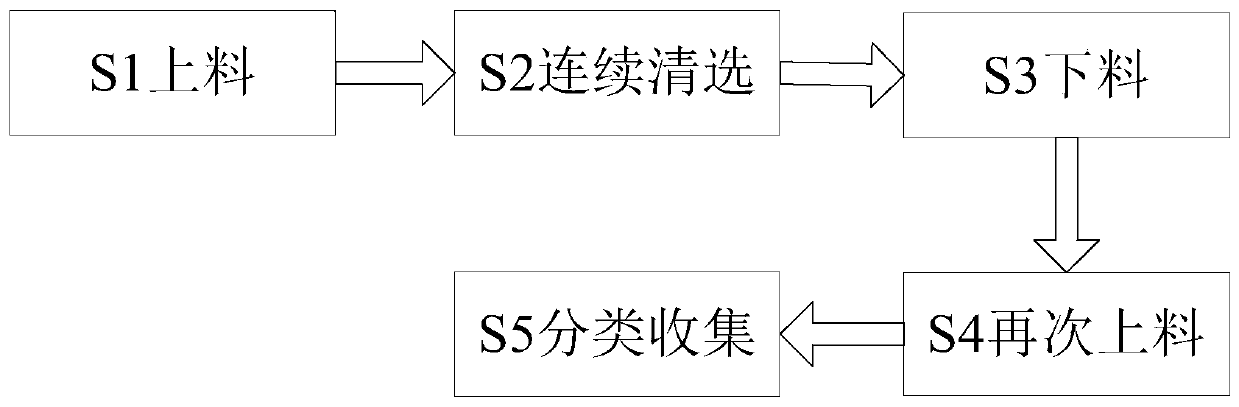

[0035] Such as Figure 1 to Figure 6 Shown, a kind of tea oil production and processing tea seed continuous cycle cleaning process, it has used a kind of automatic cleaning equipment, this automatic cleaning equipment comprises box body 1 and cleaning device 2, adopts above-mentioned automatic cleaning equipment to tea The specific method when the seeds are cleaned is as follows:

[0036] S1. Feeding: Pour the tea seeds to be cleaned in an appropriate amount into the box 1 through the feeder;

[0037] S2. Continuous cleaning: the tea seeds are continuously cleaned by the cleaning device 2 to separate waste materials such as tea seeds and grass clippings mixed in the tea seeds;

[0038] S3. Feeding: the tea seeds treated in S2 fall out from the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com