Preparation method of high-strength polyvinyl alcohol hydrogel film

A polyvinyl alcohol and hydrogel film technology, which is applied in the preparation of polyvinyl alcohol hydrogel films and the preparation of high-strength polyvinyl alcohol hydrogel films, can solve problems such as insufficient stability and mechanical properties, and achieve Excellent biocompatibility, easy control of process parameters, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

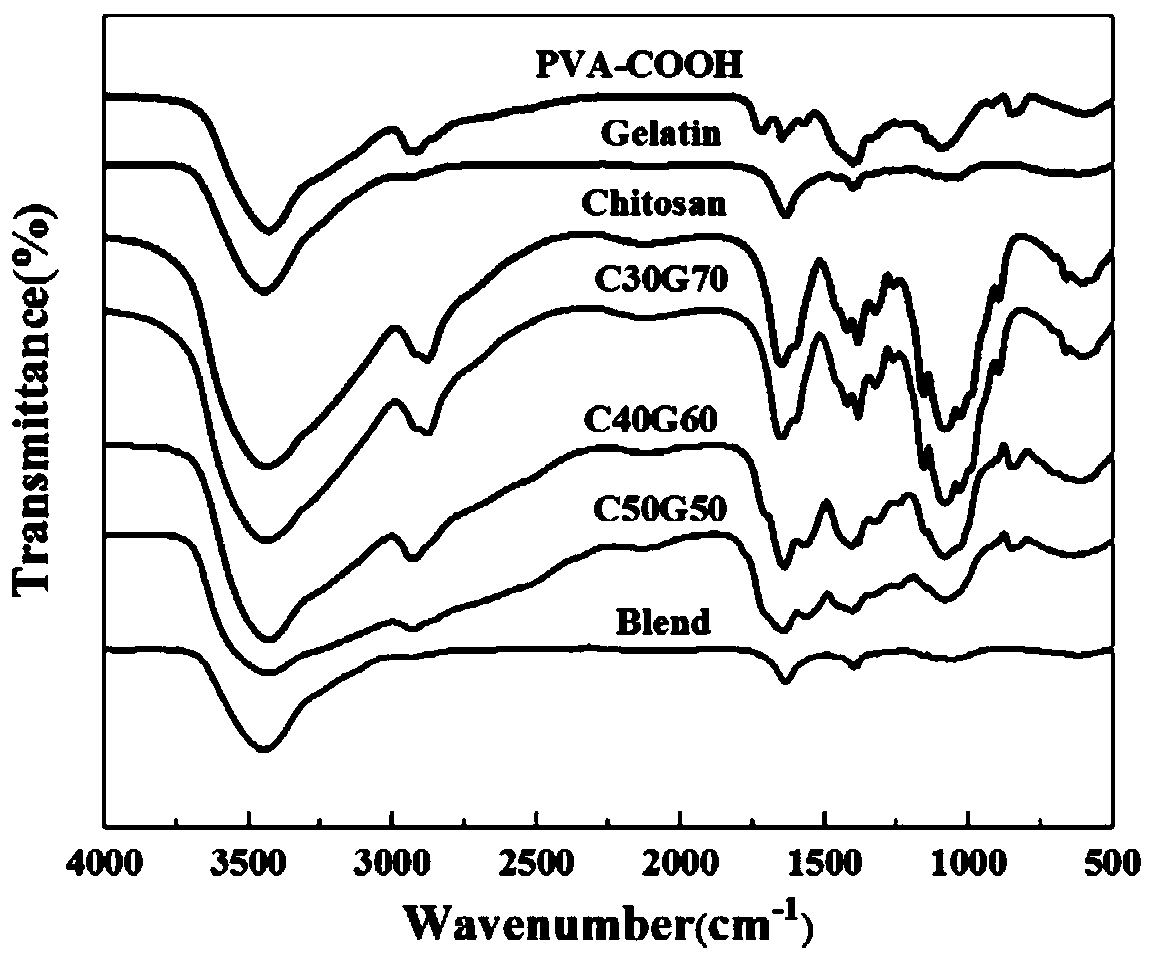

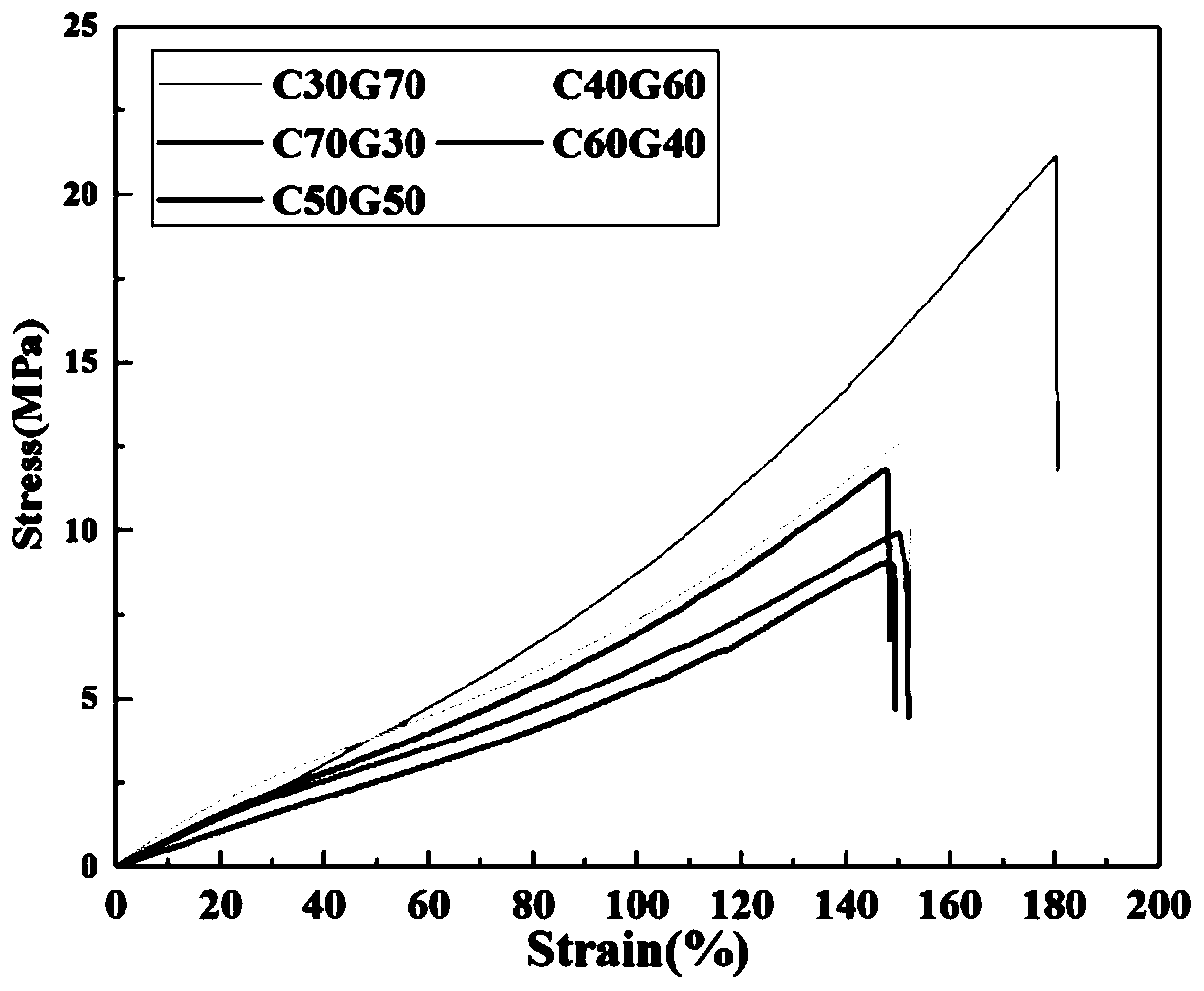

[0029] (1) The preparation of a high-strength polyvinyl alcohol hydrogel film includes the carboxylation of polyvinyl alcohol, the preparation of PVA-COOH / gelatin solution, and the preparation of PVA-COOH / gelatin / chitosan hydrogel film.

[0030] (2) The raw materials for polyvinyl alcohol carboxylation are polyvinyl alcohol, 4-dimethylaminopyridine (DMAP), and succinic anhydride; the molar ratio of raw materials is, polyvinyl alcohol: DMAP: succinic anhydride = 10: 1: 10; In addition, the mass ratio of polyvinyl alcohol to water is 1:100.

[0031] (3) The raw material of the preparation of PVA-COOH / gelatin solution is carboxylated polyvinyl alcohol, gelatin, chitosan; Raw material mass ratio is, carboxylated polyvinyl alcohol: water=1: 25, carboxylated polyvinyl alcohol: gelatin : Chitosan = 1: 0.3-0.7: 0.3-0.7; In addition, ensure carboxylated polyvinyl alcohol: (gelatin + chitosan) = 1:1.

[0032] (4) The raw materials for the preparation of PVA-COOH / gelatin / chitosan hydrog...

example 1

[0038] A. Graft modification of polyvinyl alcohol

[0039] Add 5g of PVA powder and 500mL of deionized water into a 500ml three-neck flask, and heat to 90C under constant stirring. After the polyvinyl alcohol was dissolved, the temperature of the solution was cooled to 75°C, 1.385g of DMAP was added and stirred for 1h. At 75°C, 11.36g of succinic anhydride was added to the polyvinyl alcohol blend solution, and stirred at a constant speed of 400rpm / min for 24h. After the reaction was completed, the reaction solution was cooled to room temperature, and added dropwise to the frozen acetone solution with stirring, resulting in a white precipitate. The white precipitate (PVA-COOH) was collected, washed three times with acetone to remove unreacted raw materials, dried in a vacuum oven at room temperature overnight, and stored for future use.

[0040] B, the preparation of PVA-COOH / gelatin solution

[0041] Put 2.00g of PVA-COOH powder into a three-neck flask, add 50mL of deionized ...

example 2

[0045] A. Graft modification of polyvinyl alcohol

[0046] Add 5g of PVA powder and 500mL of deionized water into a 500ml three-neck flask, and heat to 90C under constant stirring. After the polyvinyl alcohol was dissolved, the temperature of the solution was cooled to 75°C, 1.385g of DMAP was added and stirred for 1h. At 75°C, 11.36g of succinic anhydride was added to the polyvinyl alcohol blend solution, and stirred at a constant speed of 400rpm / min for 24h. After the reaction was completed, the reaction solution was cooled to room temperature, and added dropwise to the frozen acetone solution with stirring, resulting in a white precipitate. The white precipitate (PVA-COOH) was collected, washed three times with acetone to remove unreacted raw materials, dried in a vacuum oven at room temperature overnight, and stored for future use.

[0047] B, the preparation of PVA-COOH / gelatin solution

[0048] Put 2.00g of PVA-COOH powder into a three-neck flask, add 50mL of deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com