Fluid container having a releasable connection to a vehicle component

A technology for fluid containers and vehicle components, applied in the direction of vehicle components, connecting components, container filling methods, etc., to achieve the effects of firm structure, clear tactile and visual control, firm and anti-collision construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

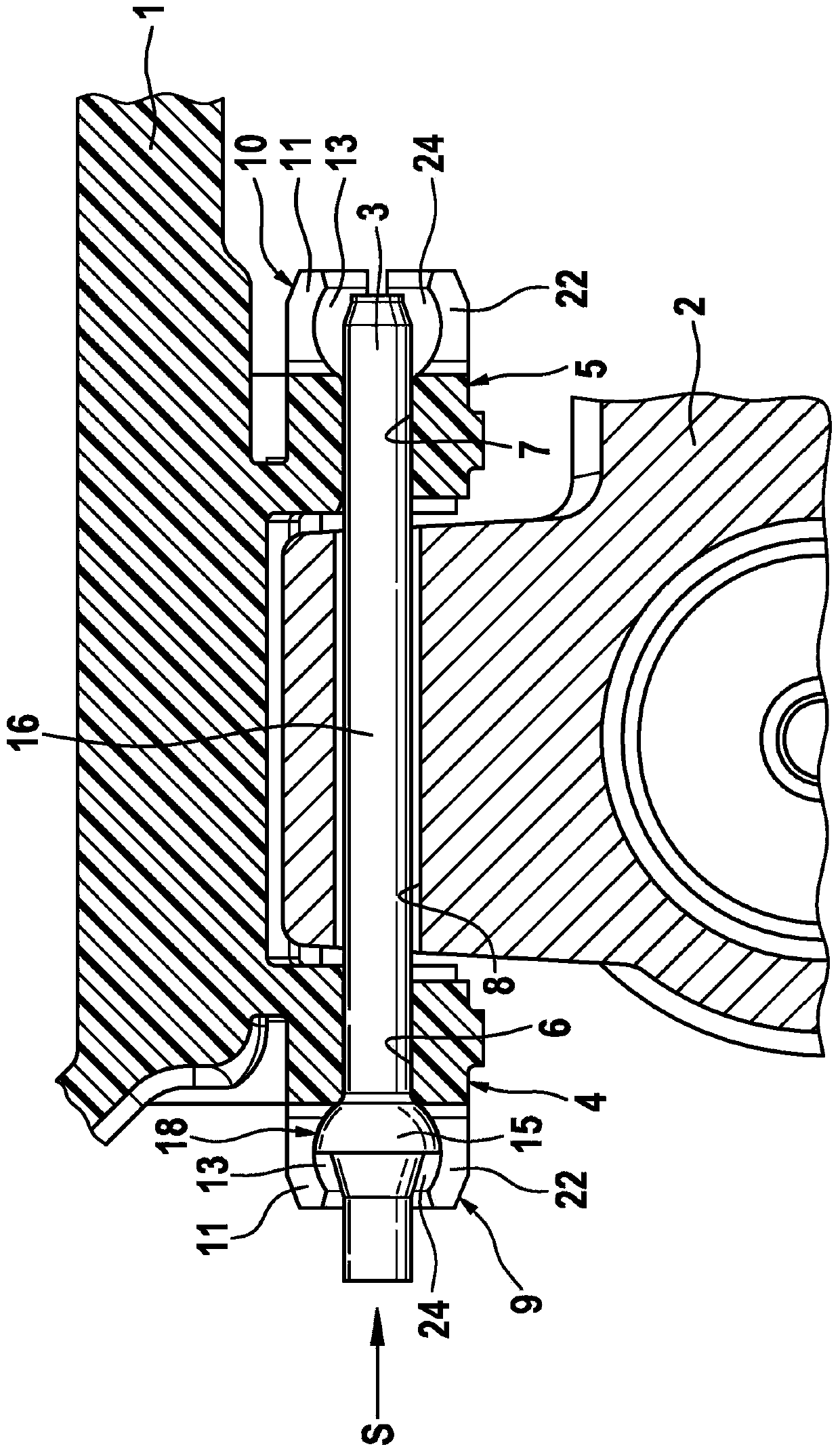

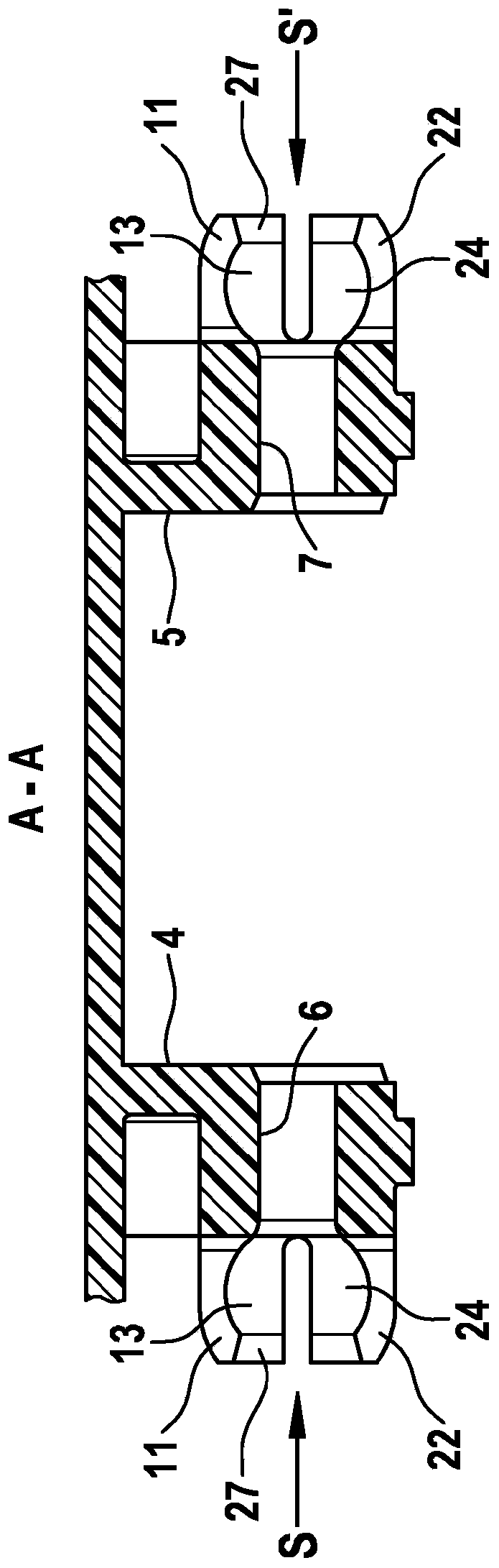

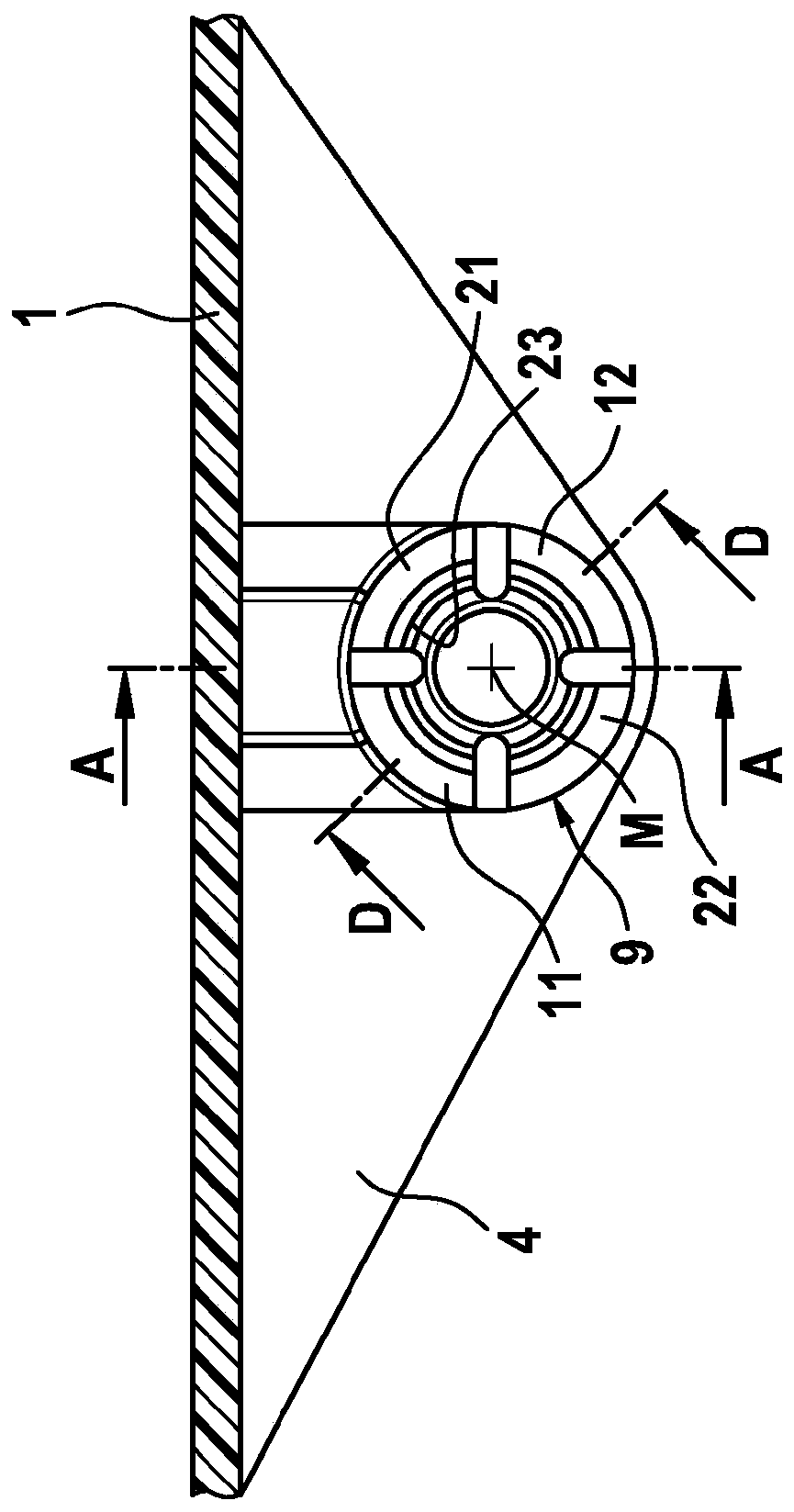

[0027] figure 1

[0028] In the embodiment shown, the fluid container 1 according to the invention is designed as a pressure medium container of a hydraulic motor vehicle brake system, which is arranged directly on the brake master cylinder (vehicle part 2 ).

[0029] The connection to the vehicle part 2 is designed to be detachable and secured by a detent pin 7 which can often be mounted or detached an unlimited number of times. For this purpose, the vehicle part 2 has an insertion opening 8, and the fluid container 1 has two fastening stations 4 and 5, which are respectively arranged on either side of the insertion opening 8 and each have an opening 6 aligned with the insertion opening 8 or 7. The openings 6 , 7 are of elongated cylindrical design in the axial direction, so that there is a sufficient contact area with the detent pin 3 . This ensures sufficient strength under high transverse forces, in particular when the limit value of the surface pressure of the plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com