Novel tire base cloth drying device

A technology of drying device and tire base cloth, which is applied in the direction of drying, drying machine, heating device, etc., can solve the problems of non-drying treatment, unfavorable product quality stability and safe production, short heat maintenance time, etc., to achieve guaranteed Stable quality and safe production, increase the difficulty of quality and safety control, and achieve the effect of stable heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

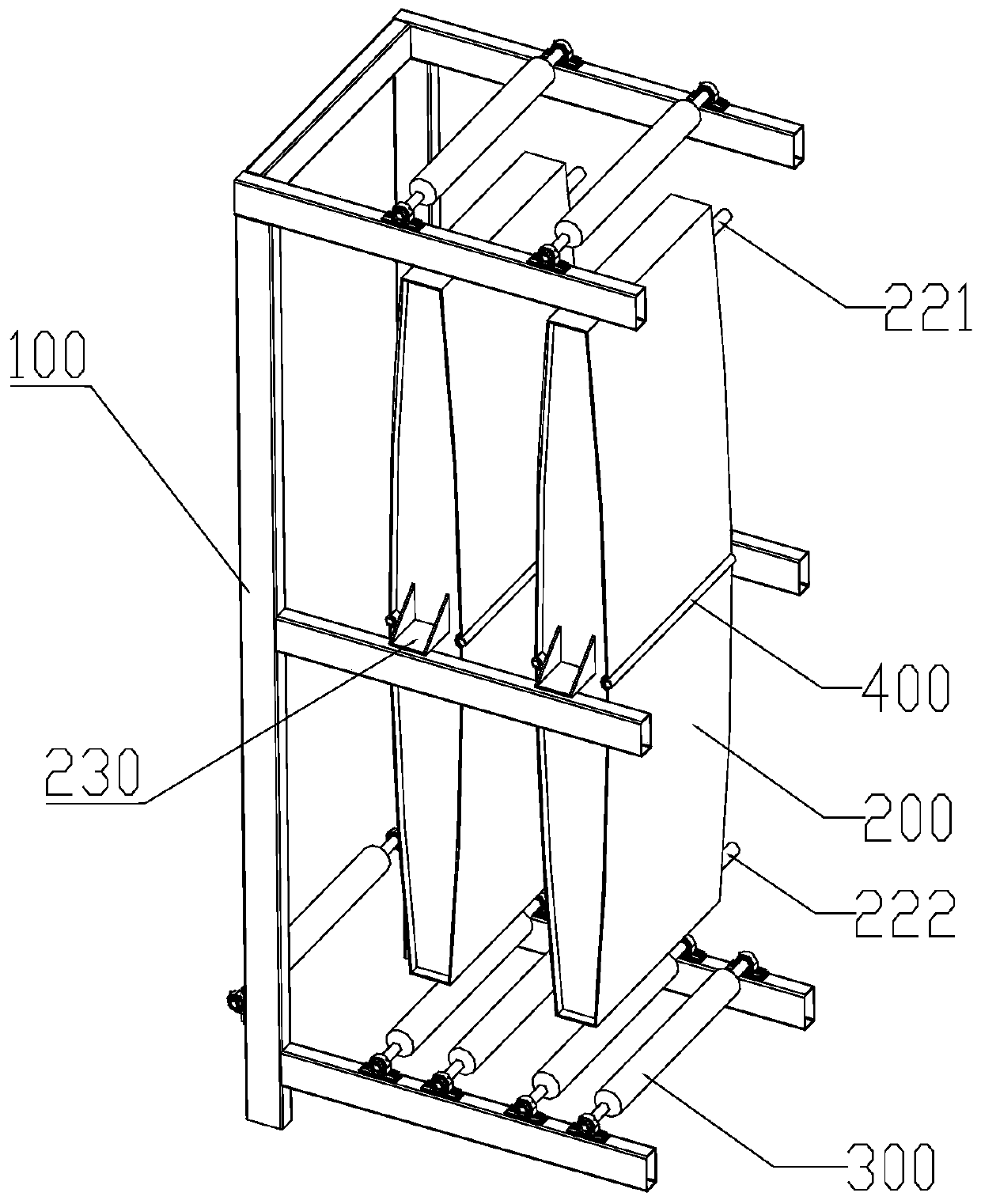

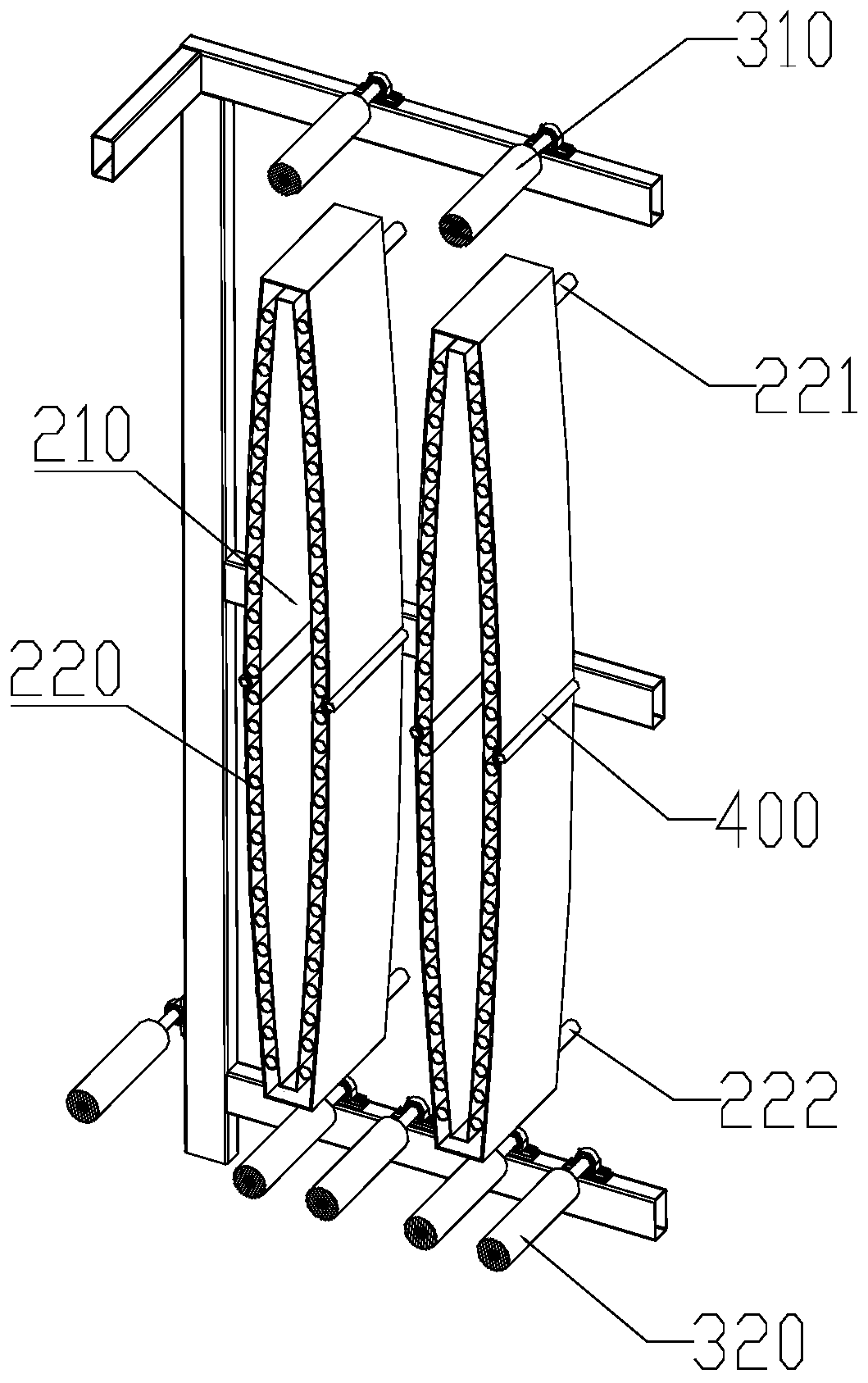

[0030] Such as figure 1 As shown, this embodiment provides a new type of tire base fabric drying device, including a frame 100 and a shuttle-shaped dryer 200 arranged side by side, and the shuttle-shaped dryer 200 is used to realize the heating of the tire base fabric Drying also includes a guide roller 300 and a push rod 400. The guide roller 300 includes an upper guide roller 310 and a lower guide roller 320 respectively arranged above and below the shuttle dryer 200, and the tire base cloth passes through the lower guide roller 320. Winding from one side of the shuttle dryer 200 to the upper guide roller 310, and then winding to the lower guide roller 320 from the other side of the shuttle dryer 200, the ejector rod 400 is arranged on the shuttle The two sides of the shuttle-shaped dryer 200 are used to prop up the tire base cloth from the side so that there is a gap between the tire base cloth and the surface of the shuttle-shaped dryer 200 .

[0031] Specifically, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com