Water seepage prevention structure and construction method of tower crane foundation in basement floor of building

A basement floor and tower crane foundation technology, which is applied to foundation structure engineering, construction, gaskets, etc., and can solve problems such as disturbance, floor seepage, and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

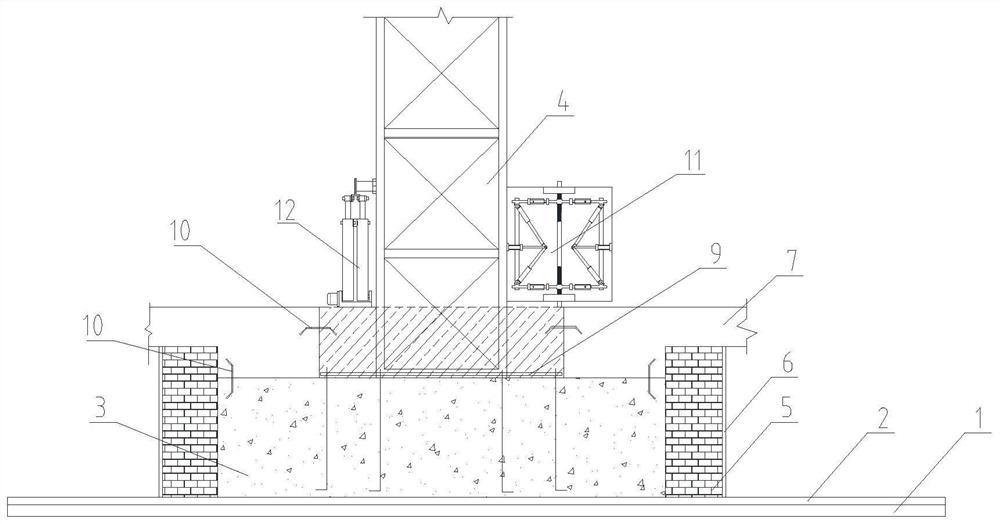

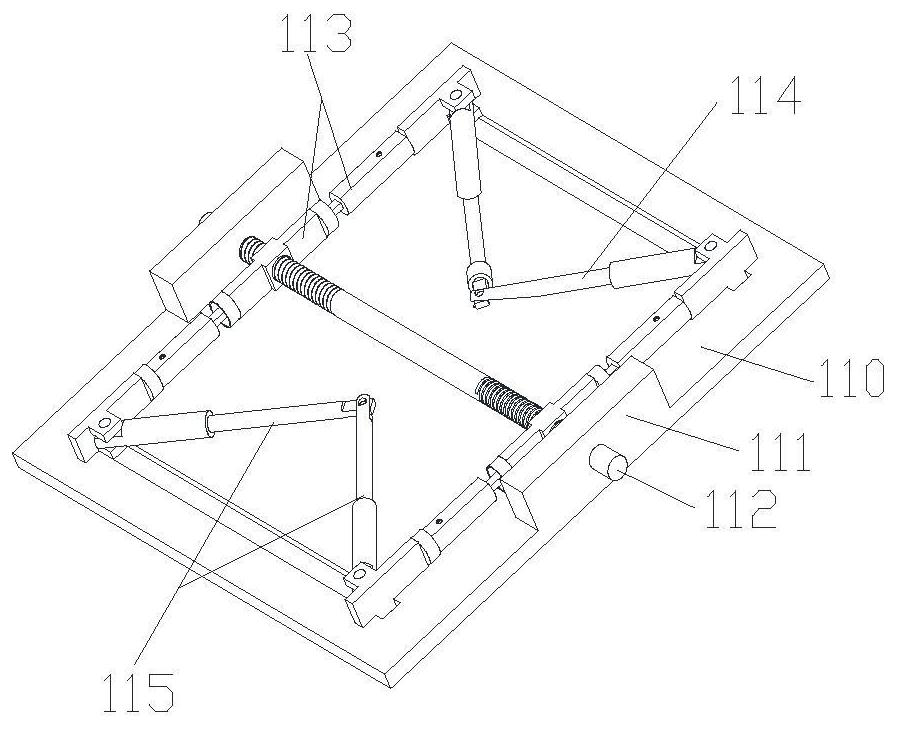

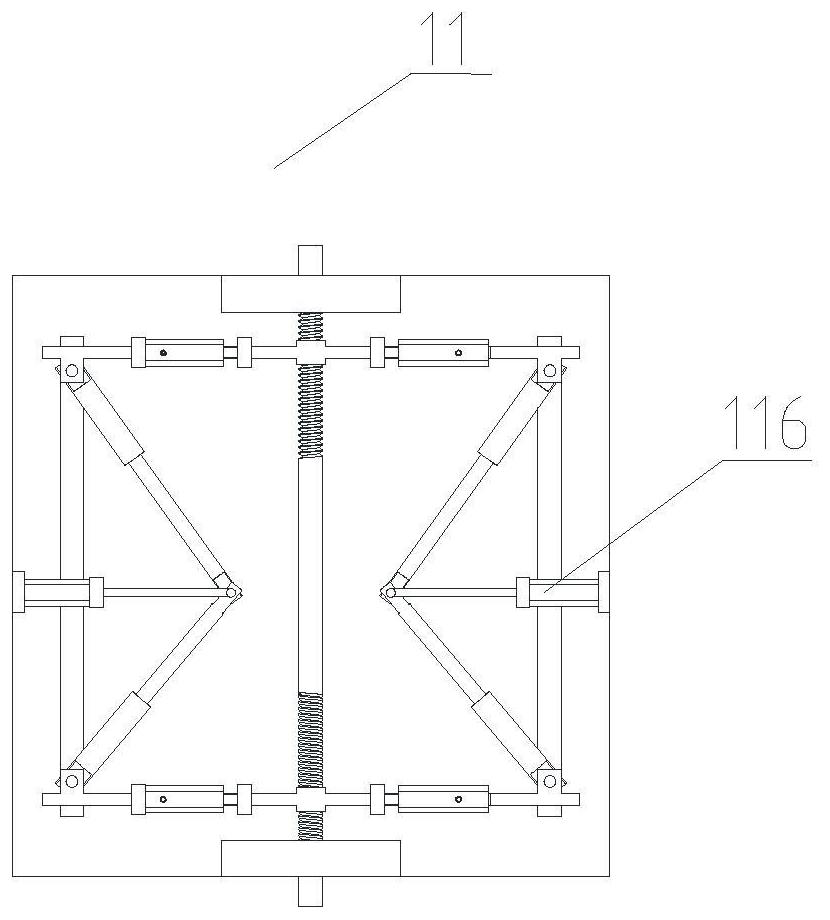

[0035] see Figure 1 to Figure 5 , the technical solution provided by the present invention is, a tower crane foundation anti-seepage structure in the basement floor of a building, which includes a reinforced concrete floor 1, a waterproof protective layer 2 arranged on the reinforced concrete floor 1, and is arranged on the waterproof protective layer 2 The tower crane bearing base 3 formed by pouring several I-beams arranged side by side, and the tower crane base 4 poured on the top of the tower crane bearing base 3;

[0036] The anti-seepage structure of the tower crane foundation in the basement floor of the building also includes two brick membranes 5 respectively arranged on both sides of the reinforced concrete floor 1, a waterproof coiled material 6 laid on the bottom side of the wall of the two brick membranes 5, and two brick tires. Two basement baseboards 7 are arranged on the top surface of the membrane 5, tower crane foundations 4 are arranged inside the two basem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com