Preparation method of water-repellent canvas

A canvas and melt technology, applied in the fiber field, can solve the problems of poor mechanical properties, poor adhesion between waterproof coating and polyester, poor dyeing performance of canvas base fabric, etc., to improve mechanical properties, increase crystallinity and orientation degree , the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

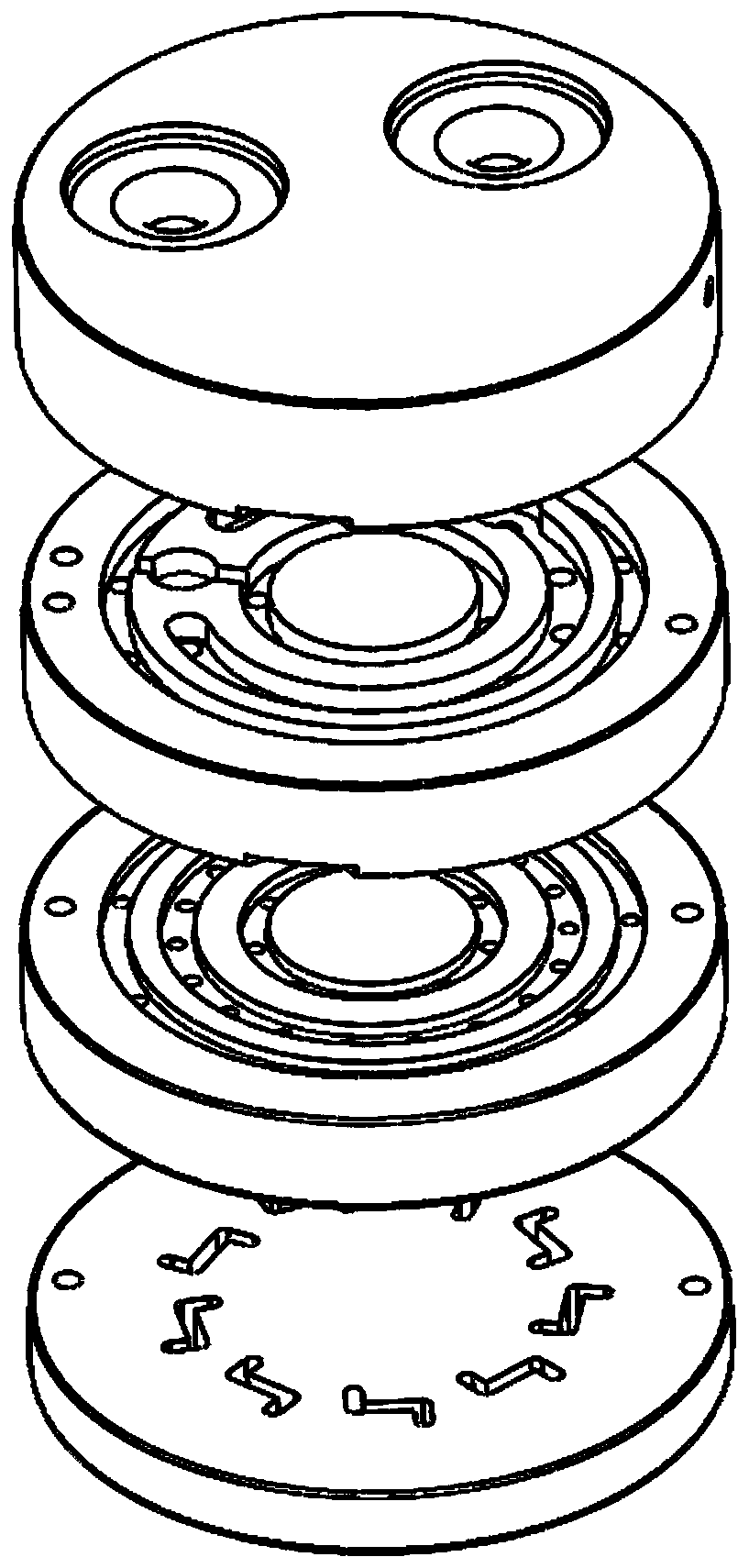

Image

Examples

Embodiment 1

[0051] A preparation method of water-repellent canvas, the steps are as follows:

[0052] (1) Prepared from twisted fibers:

[0053] According to the spinning process, the low-viscosity CDP melt (intrinsic viscosity of 0.71dL / g) and the high-viscosity CDP melt (intrinsic viscosity of 1.2dL / g) in a mass ratio of 55:45 were dispensed from the same spinneret. After extruding the spinneret hole on the upper part to obtain the industrial yarn, it is subjected to relaxation heat treatment to obtain the self-twisting fiber;

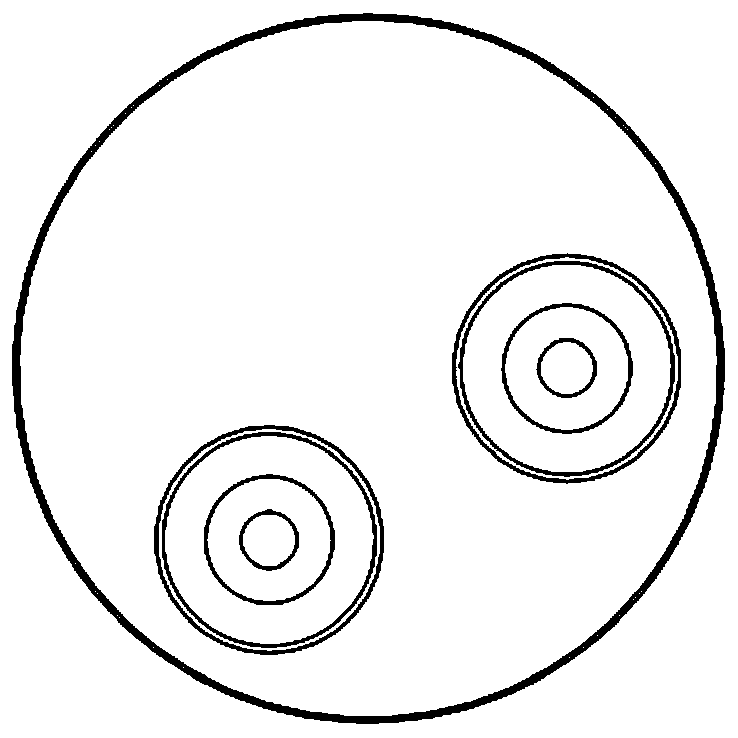

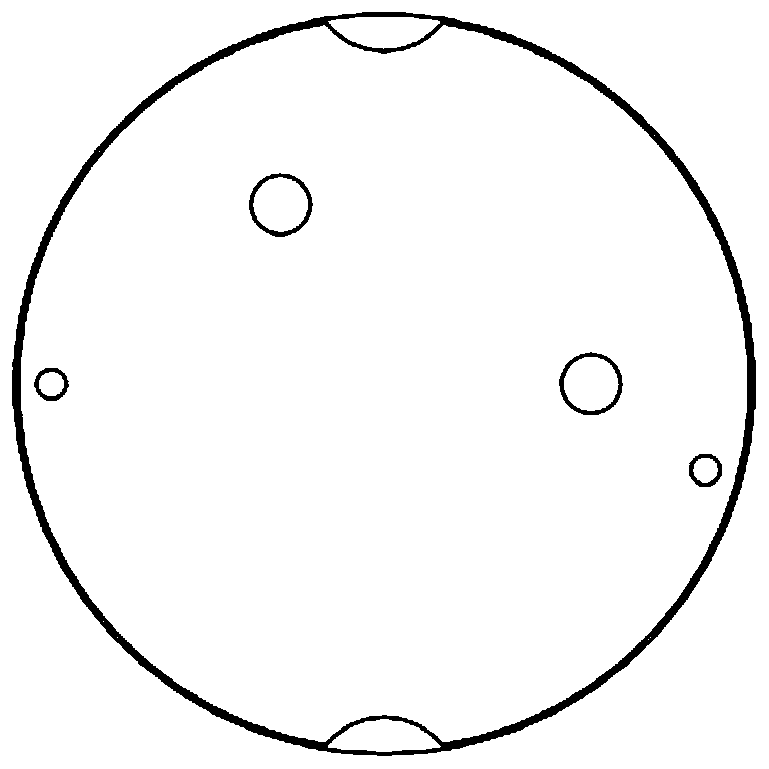

[0054] like Figure 8 As shown, the spinneret holes on the spinneret are shaped spinneret, The shape is composed of horizontal lines and vertical lines I and II vertically connected to them; the widths of horizontal lines, vertical lines I and vertical lines are the same; the ratio of the lengths of vertical lines I to vertical lines II is 1:2.1, and the vertical lines The ratio of the length of II to the length of the horizontal line is 4:10; the ratio of...

Embodiment 2

[0066] A preparation method of water-repellent canvas, the steps are as follows:

[0067] (1) Prepared from twisted fibers:

[0068] According to the spinning process, the low-viscosity CDP melt (intrinsic viscosity of 0.73dL / g) and the high-viscosity CDP melt (intrinsic viscosity of 1.23dL / g) in a mass ratio of 65:35 were dispensed from the same spinneret. After extruding the spinneret hole on the upper part to obtain the industrial yarn, it is subjected to relaxation heat treatment to obtain the self-twisting fiber;

[0069] The spinneret is shaped spinneret, The shape is composed of horizontal lines and vertical lines I and II vertically connected to them; the widths of horizontal lines, vertical lines I and vertical lines are the same; the ratio of the lengths of vertical lines I to vertical lines II is 1:2.1, and the vertical lines The ratio of the length of II to the length of the horizontal line is 5:10; the ratio of the length to the width of the horizontal line i...

Embodiment 3

[0081] A preparation method of water-repellent canvas, the steps are as follows:

[0082] (1) Prepared from twisted fibers:

[0083] According to the spinning process, the low-viscosity CDP melt (intrinsic viscosity of 0.7dL / g) and the high-viscosity CDP melt (intrinsic viscosity of 1.1dL / g) in a mass ratio of 60:40 were dispensed from the same spinneret. After extruding the spinneret hole on the upper part to obtain the industrial yarn, it is subjected to relaxation heat treatment to obtain the self-twisting fiber;

[0084] The spinneret is shaped spinneret, The shape is composed of horizontal lines and vertical lines I and II vertically connected to them; the widths of horizontal lines, vertical lines I and vertical lines are the same; the ratio of the lengths of vertical lines I to vertical lines II is 1:1.8, and the vertical lines The ratio of the length of II to the length of the horizontal line is 4:10; the ratio of the length to the width of the horizontal line is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com