High-adaptability low-cost nickel chromium-nickel silicon thermocouple wire and production process thereof

A technology of thermocouple wire and production process, which is applied in the field of high adaptability and low cost nickel-chromium-nickel-silicon thermocouple wire and its production process, can solve the problems of high production cost, unrecommended, poor adaptability, etc., so as to prolong the service life , The effect of reducing temperature measurement deviation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

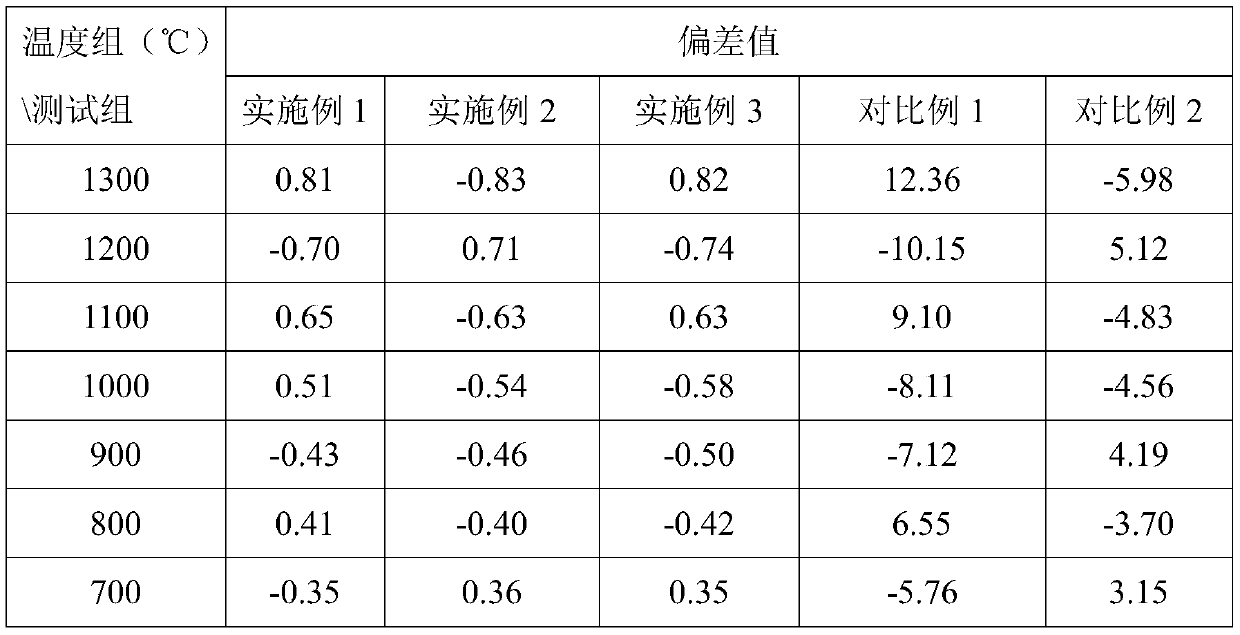

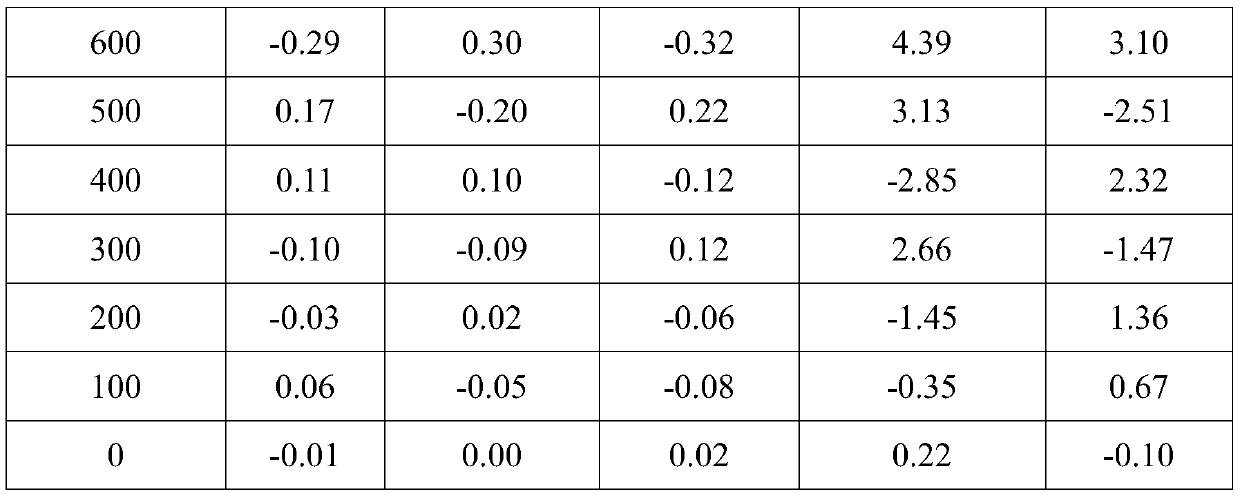

Embodiment 1

[0034] A high-adaptability low-cost nickel-chromium-nickel-silicon thermocouple wire, including a positive electrode galvanic wire and a negative electrode galvanic wire, the negative electrode galvanic wire is a nickel-based alloy wire, and the nickel-based alloy wire has a weight percentage of Unit, including the following raw materials: 0.3% cobalt, 0.05% yttrium, 0.1% vanadium, 0.5% titanium, 1.0% iron, 2.0% aluminum, 0.05% niobium, 0.05% molybdenum, 6.5% chromium, 0.5% vanadium, 0.5 % tungsten, 2.0% manganese, 0.05% gallium, 0.5% silicon, the balance being nickel.

[0035] A high-adaptability low-cost nickel-chromium-nickel-silicon thermocouple wire production process, including the production of positive and negative galvanic wires, welding the produced positive and negative galvanic wires to obtain nickel Chromium-nickel-silicon thermocouple wire; the production of the negative electrode wire comprises the following steps:

[0036] 1) Ingredients: prepare raw materials...

Embodiment 2

[0053] A high-adaptability low-cost nickel-chromium-nickel-silicon thermocouple wire, including a positive electrode galvanic wire and a negative electrode galvanic wire, the negative electrode galvanic wire is a nickel-based alloy wire, and the nickel-based alloy wire has a weight percentage of Unit, including the following raw materials: 0.7% cobalt, 0.1% yttrium, 0.3% vanadium, 1.0% titanium, 1.5% iron, 2.5% aluminum, 0.1% niobium, 0.1% molybdenum, 7.0% chromium, 0.9% vanadium, 0.9% tungsten, 2.5% manganese, 0.1% gallium, 0.5-1.0% silicon, and the balance is nickel. .

[0054] A high-adaptability low-cost nickel-chromium-nickel-silicon thermocouple wire production process, including the production of positive and negative galvanic wires, welding the produced positive and negative galvanic wires to obtain nickel Chromium-nickel-silicon thermocouple wire; the production of the negative electrode wire comprises the following steps:

[0055] 1) Ingredients: prepare raw materi...

Embodiment 3

[0072] A high-adaptability low-cost nickel-chromium-nickel-silicon thermocouple wire, including a positive electrode galvanic wire and a negative electrode galvanic wire, the negative electrode galvanic wire is a nickel-based alloy wire, and the nickel-based alloy wire has a weight percentage of Unit, including the following raw materials: 1.0% cobalt, 0.2% yttrium, 0.5% vanadium, 2.0% titanium, 2.0% iron, 3.0% aluminum, 0.2% niobium, 0.2% molybdenum, 8.5% chromium, 1.3% vanadium, 1.3% tungsten, 3.0% manganese, 0.2% gallium, 1.0% silicon, the balance being nickel.

[0073] A high-adaptability low-cost nickel-chromium-nickel-silicon thermocouple wire production process, including the production of positive and negative galvanic wires, welding the produced positive galvanic wire and negative galvanic wire to obtain nickel Chromium-nickel-silicon thermocouple wire; the production of the negative electrode wire comprises the following steps:

[0074] 1) Ingredients: prepare raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com