Graphene/silicon carbide reinforced copper-based composite material and preparation method thereof

A technology of copper-based composite materials and composite materials, which is applied in the field of graphene/silicon carbide reinforced copper-based composite materials and its preparation, can solve the problem of low comprehensive performance of graphene-copper-based composite materials, large specific surface area of graphene, and practical process Complicated problems, to achieve good application prospects, fine matrix grains, raw material selection and reasonable proportioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

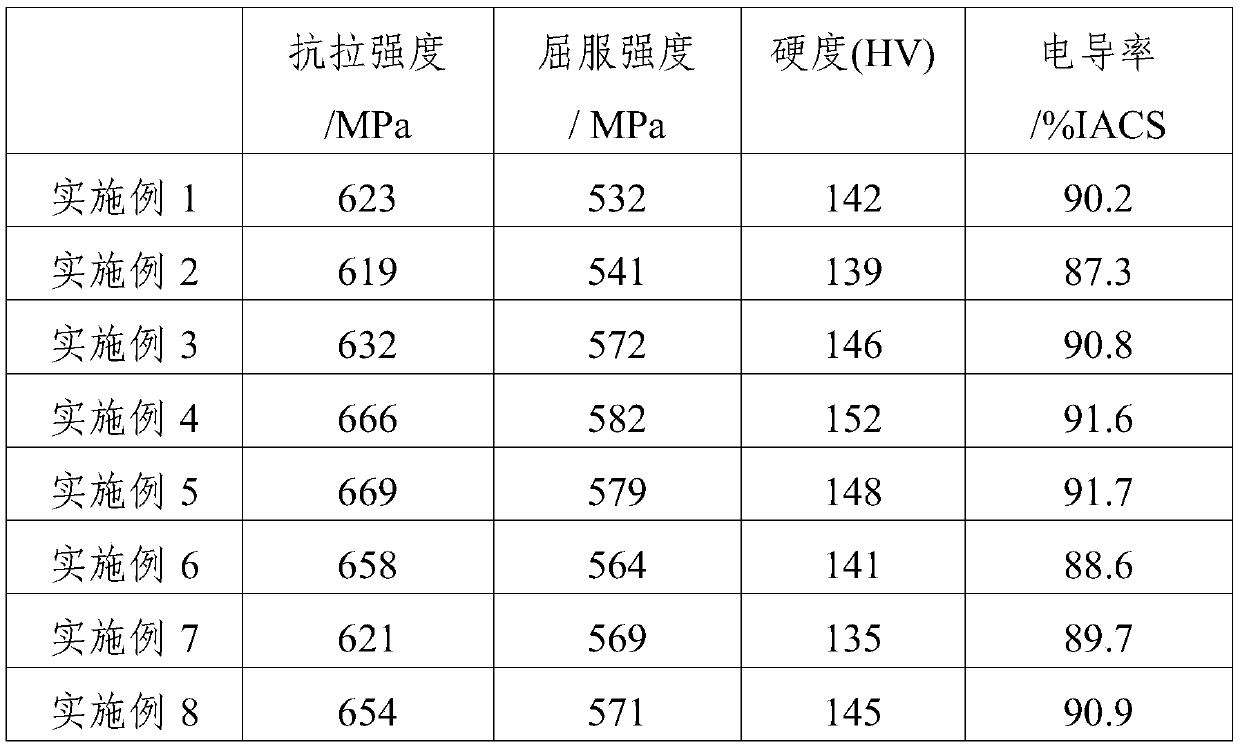

Examples

Embodiment 1

[0030] A graphene / silicon carbide reinforced copper-based composite material, which contains the following components in weight percentage: graphene: 0.5wt%, SiC: 0.6wt%, Ni: 0.1wt%, and the balance is copper.

[0031] The preparation method of above-mentioned graphene / silicon carbide reinforced copper matrix composite material, comprises the following steps:

[0032] (1) The original copper powder is pretreated. The method is: put the original copper powder in a 5mol / L acetic acid solution for 20 minutes; after cleaning with distilled water, place it in ethanol and propanol for 25 minutes, filter, and vacuum dry. instant;

[0033] Pre-mix the pretreated copper powder, ultrafine silicon carbide powder, and nickel powder in a high-speed mixer for 10 hours to obtain a mixed powder;

[0034] The particle size of the above raw copper powder is 1-5 μm; the particle size of the superfine silicon carbide powder is 20-50 nm; the particle size of the nickel powder is 10-20 μm.

[003...

Embodiment 2

[0042] A graphene / silicon carbide reinforced copper-based composite material, which contains the following components in weight percentage: graphene: 0.45wt%, SiC: 0.4wt%, Ni: 0.05wt%, and the balance is copper.

[0043] The preparation method of above-mentioned graphene / silicon carbide reinforced copper matrix composite material, comprises the following steps:

[0044] (1) The original copper powder is pretreated. The method is: put the original copper powder in a 5mol / L acetic acid solution for 20 minutes; after cleaning with distilled water, place it in ethanol and propanol for 25 minutes, filter, and vacuum dry. instant;

[0045] Pre-mix the pretreated copper powder, ultrafine silicon carbide powder, and nickel powder in a high-speed mixer for 10 hours to obtain a mixed powder;

[0046] The particle size of the above original copper powder is 1-5 μm; the particle size of the superfine silicon carbide powder is 20-50 nm; the particle size of the nickel powder is 10-20 μm. ...

Embodiment 3

[0054] A graphene / silicon carbide reinforced copper-based composite material, which contains the following components in weight percentage: graphene: 0.55wt%, SiC: 0.55wt%, Ni: 0.12wt%, and the balance is copper.

[0055] The preparation method of above-mentioned graphene / silicon carbide reinforced copper matrix composite material, comprises the following steps:

[0056] (1) The original copper powder is pretreated. The method is: put the original copper powder in a 5mol / L acetic acid solution for 20 minutes; after cleaning with distilled water, place it in ethanol and propanol for 25 minutes, filter, and vacuum dry. instant;

[0057] Pre-mix the pretreated copper powder, ultrafine silicon carbide powder, and nickel powder in a high-speed mixer for 8 hours to obtain a mixed powder;

[0058] The particle size of the above original copper powder is 1-5 μm; the particle size of the superfine silicon carbide powder is 20-50 nm; the particle size of the nickel powder is 10-20 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com