A tape cutting machine capable of automatic edge folding

A cutting machine and adhesive tape technology, which is applied in transportation packaging, thin material handling, packaging, etc., can solve problems such as tape tearing and slow packaging opening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

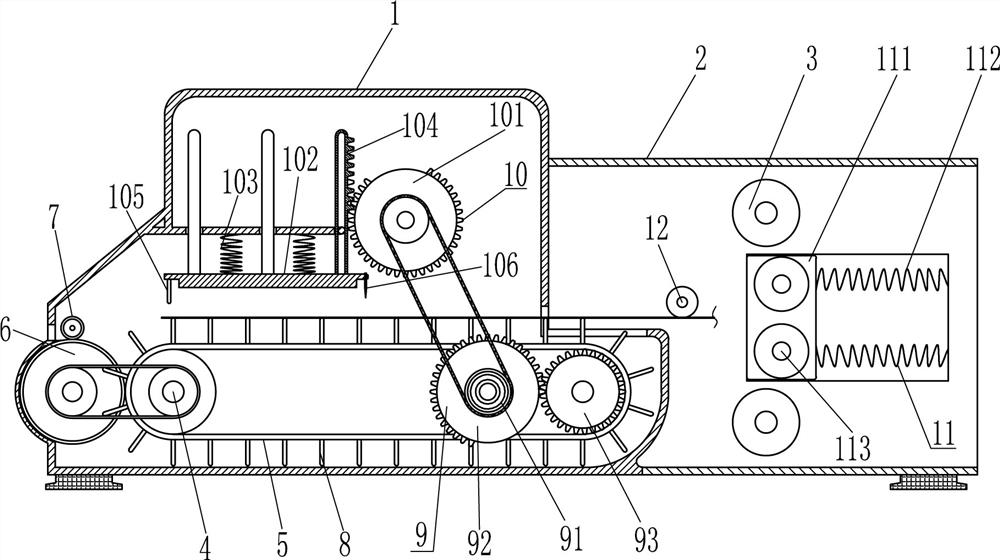

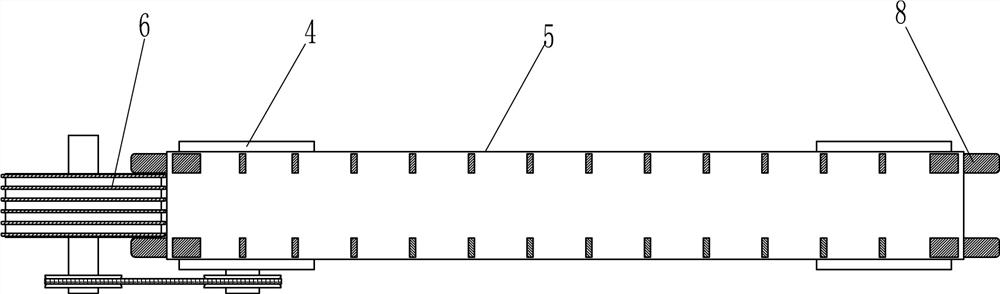

[0017] refer to Figure 1-2 , a tape cutting machine capable of automatic folding, including an organic casing 1, an installation frame 2, a limit roller 3, a conveying roller 4 and a conveyor belt 5, the right side of the casing 1 is provided with an installation frame 2, and the installation frame 2 and The casings 1 are connected by bolts. The upper and lower parts of the installation frame 2 are symmetrically provided with limit rollers 3. The limit rollers 3 are used to limit the tape. The left and right sides of the lower part of the casing 1 are rotating. There are conveying rollers 4, and the conveying rollers 4 on the left and right sides are symmetrically arranged, and a conveying belt 5 is wound between the left and right conveying rollers 4, and also includes a conveying roller 6, a pressure roller 7, a paddle 8, a transmission assembly 9 and Cutting assembly 10, the front and rear sides of the conveyor belt 5 are evenly distributed with paddles 8, the paddles 8 ar...

no. 2 example

[0024] refer to figure 1 , also includes a pressing assembly 11, the pressing assembly 11 includes a slide plate 111, a compression spring 112 and a pressing roller 113, a sliding plate 111 is provided in the installation frame 2, and a compression spring is connected between the slide plate 111 and the installation frame 2 112, the front side of the slide plate 111 is rotatably provided with two pinch rollers 113, and the pinch rollers 113 are located between the upper and lower limit rollers 3.

[0025] Pull the slide plate 111 to move to the right, the pressure roller 113 moves accordingly, the compression spring 112 is compressed, then the tape roll passes through the pressure roller 113, and then the slide plate 111 is released, under the action of the compression spring 112, the pressure roller 113 resets , and clamp the side ring of the tape roll between the limit roller 3 and the pinch roller 113, the compression spring 112 is in a semi-compressed state, and as the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com