Multi-tooth transmission propeller

A technology of propeller and gear transmission, which is applied to propellers, transmission devices for driving multiple propellers, aircraft parts, etc., can solve the problems of increasing weight, increasing the complexity of engine design, and high noise, so as to improve power level and improve operation Speed and reliability, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with accompanying drawing:

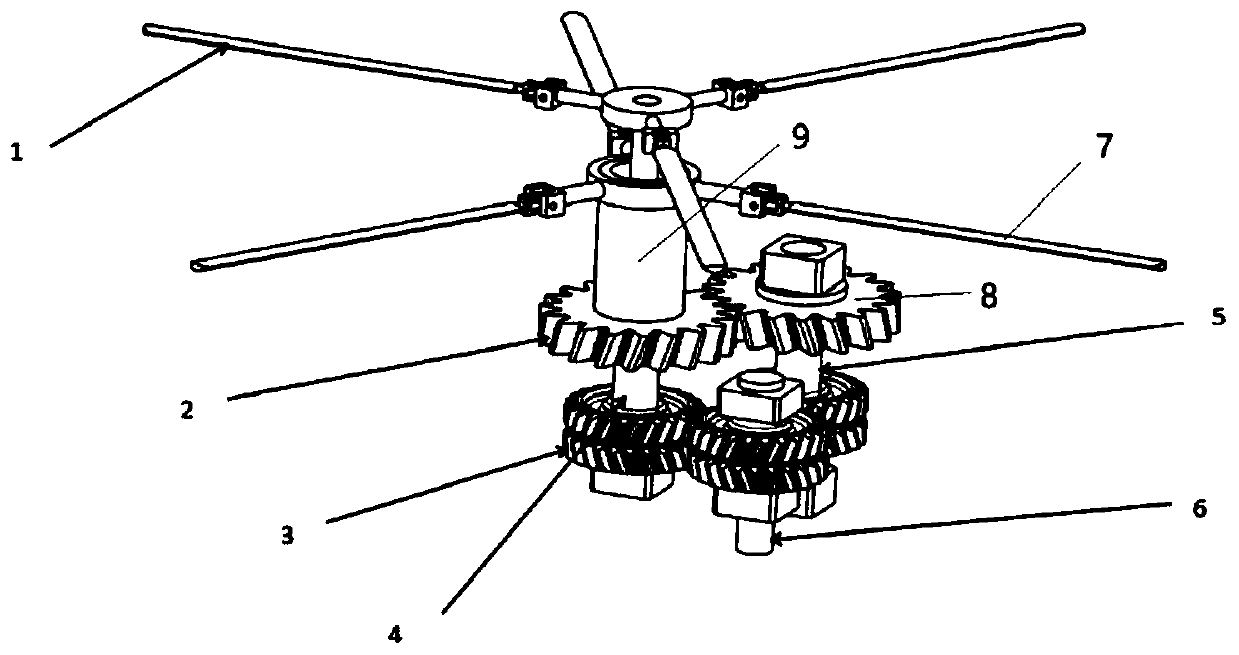

[0023] see Figure 1 to Figure 3 , a multi-tooth transmission propeller, including a first propeller 1, a second propeller 7, a first helical gear 2, a first transmission shaft 4 and a transmission gear set; the first propeller 1 is arranged on the top of the first transmission shaft 4, and the second The first transmission shaft 4 below the propeller 1 is provided with a first helical gear 2 through a bearing, and the second propeller 7 is arranged on the first helical gear 2; the transmission gear set connects the first transmission shaft 4 and the first helical gear 2, The first propeller 1 and the second propeller 7 are coaxially reversed.

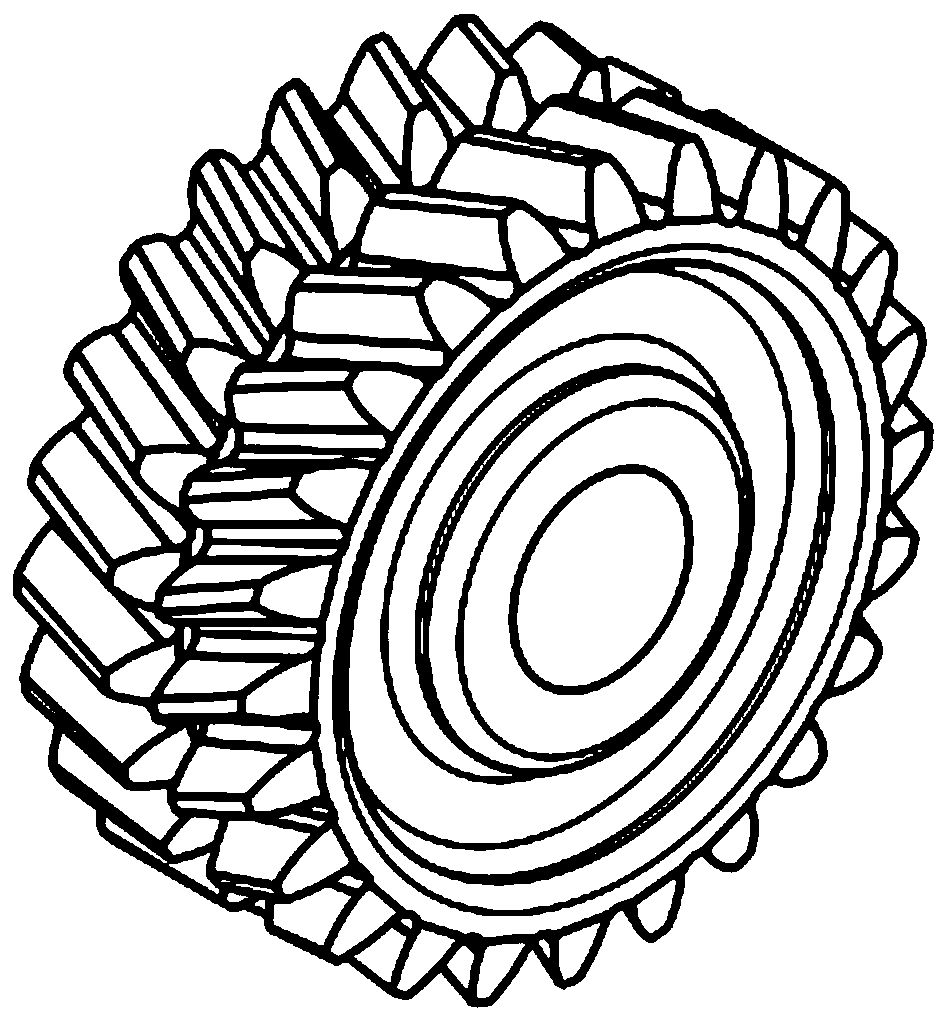

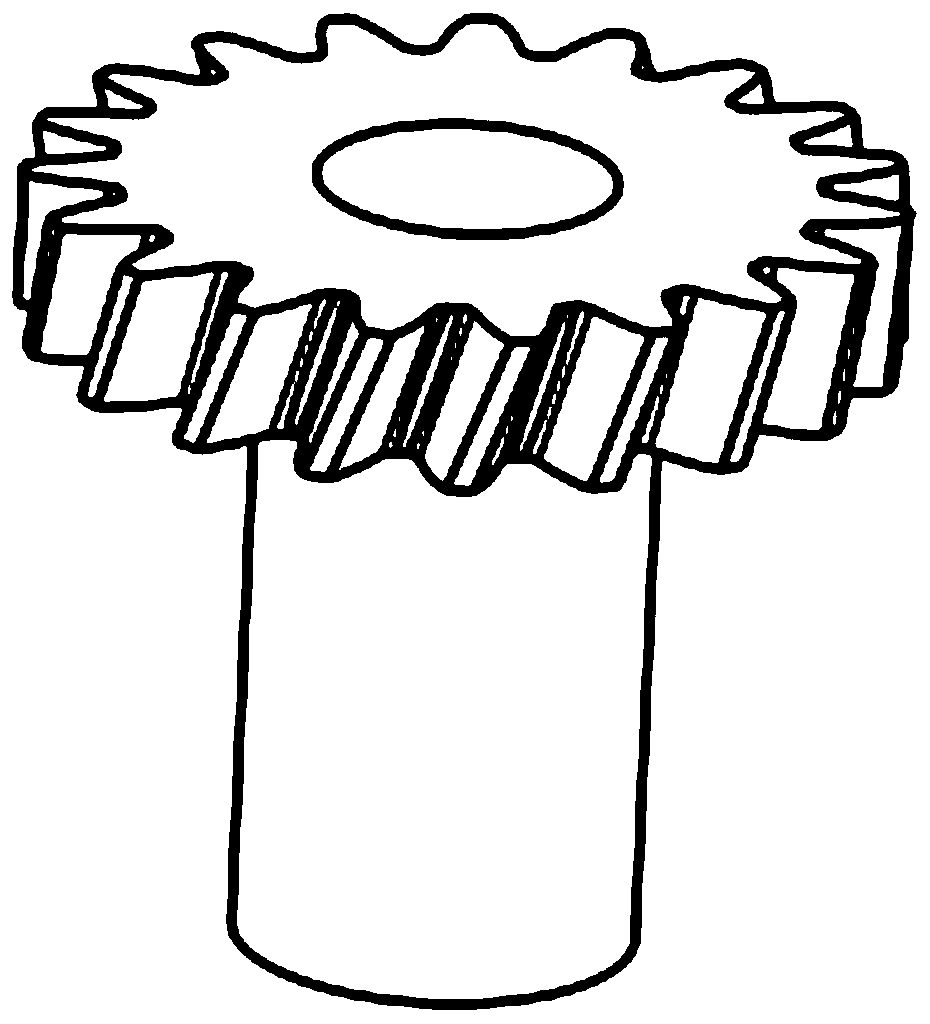

[0024] The transmission gear set includes the herringbone gear 3, the second transmission shaft 5, the second helical gear 8 and the third transmission shaft 6; The gear 3 and the three herringbone gears 3 mesh with each other; the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com