A high-durability concrete drainage pipe and its production process

A technology for concrete pipes and production processes, which can be used in sewer pipeline systems, manufacturing tools, reinforcement molding, etc., and can solve problems such as damage, wear and corrosion of SBS leak-proof coil layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

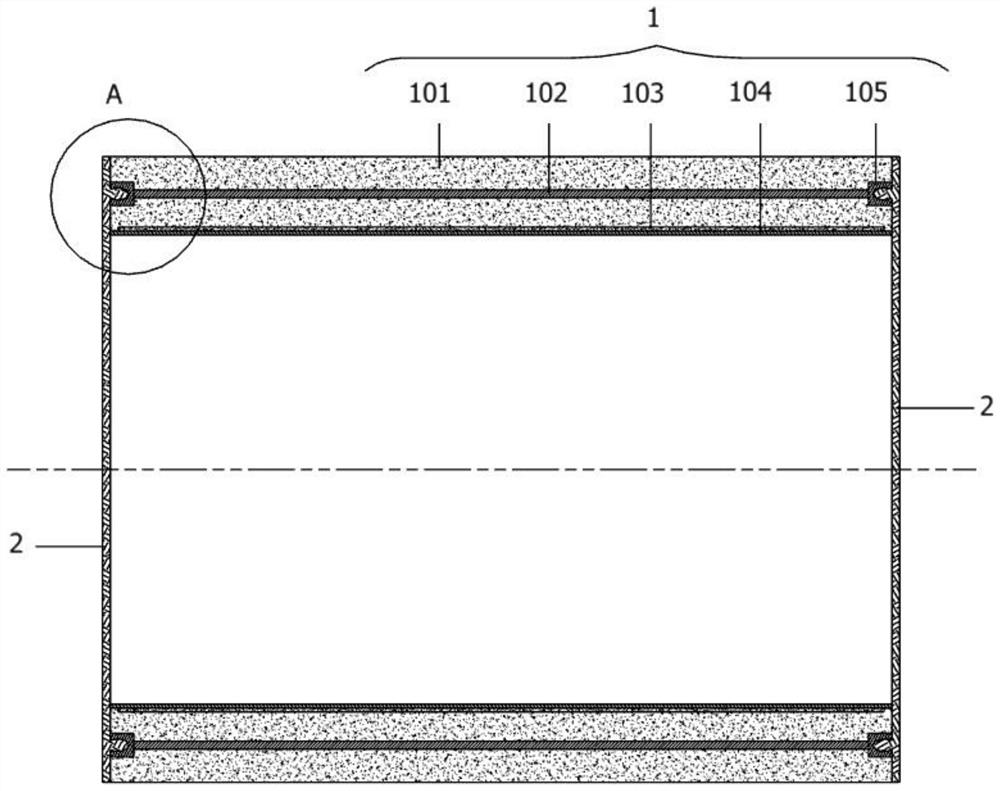

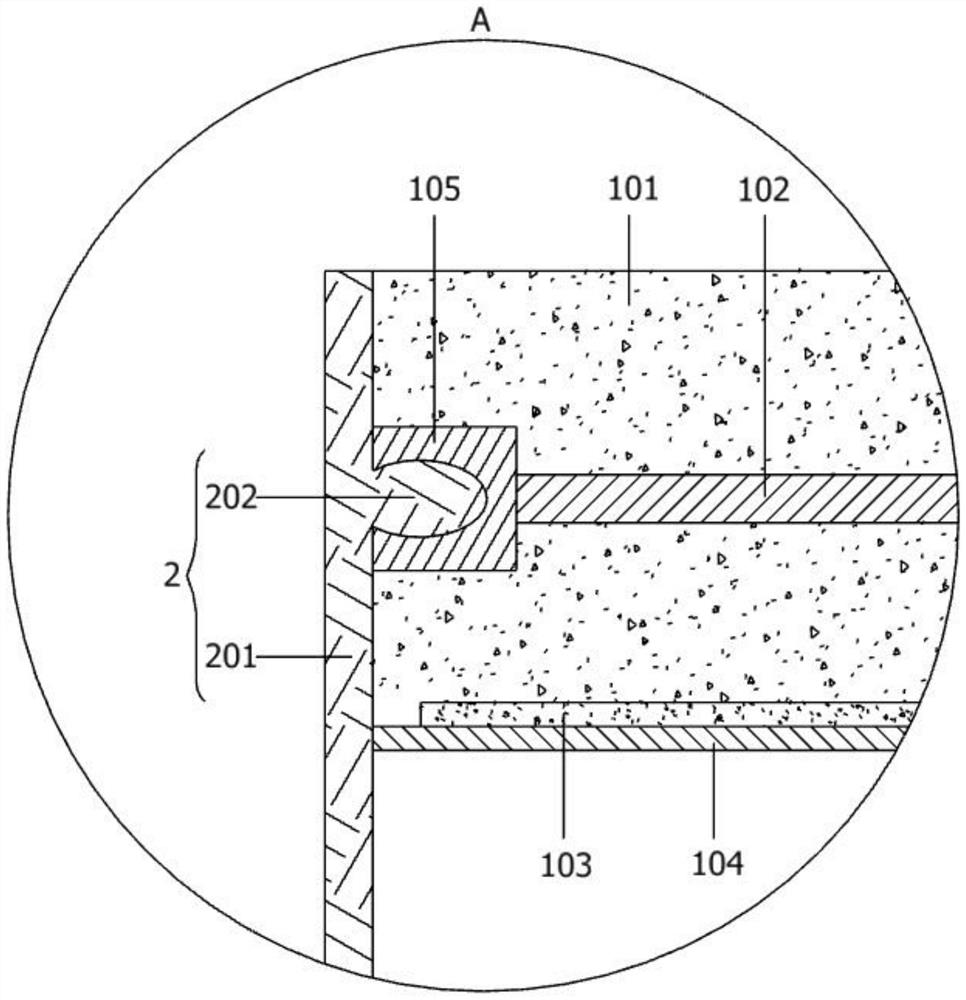

[0035] as attached figure 1 To attach Figure 6 Shown:

[0036] The invention provides a high-durability concrete drainage pipe and its production process, comprising: a concrete drainage pipe 1, and a set of rubber isolation mechanisms 2 are sealed and fastened to the open ends of the left and right sides of the concrete drainage pipe 1 .

[0037] Among them, the concrete drainage pipe 1 includes a concrete pipe body 101, a steel skeleton 102, a pigment filling layer 103, an SBS leak-proof coiled material layer 104, a ring-shaped nylon reserved block 105, a ring-shaped elliptical limit embedding groove 106, and the concrete pipe The inside of the body 101 is pre-wrapped with a steel skeleton 102, and the left and right ends of the steel skeleton 102 are fixedly connected with a ring-shaped nylon reserved block 105. The surface is at the same level, the right end face of the ring-shaped nylon reserved block 105 on the right side is at the same level as the right end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com