Convertible internal and external engraving laser equipment

A laser equipment and transforming technology, applied in the field of laser applications, can solve the problems of difficult clamping of workpieces, poor workbench protection, no laser safety partitions, etc., and achieve the effects of simple structure, convenient replacement and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

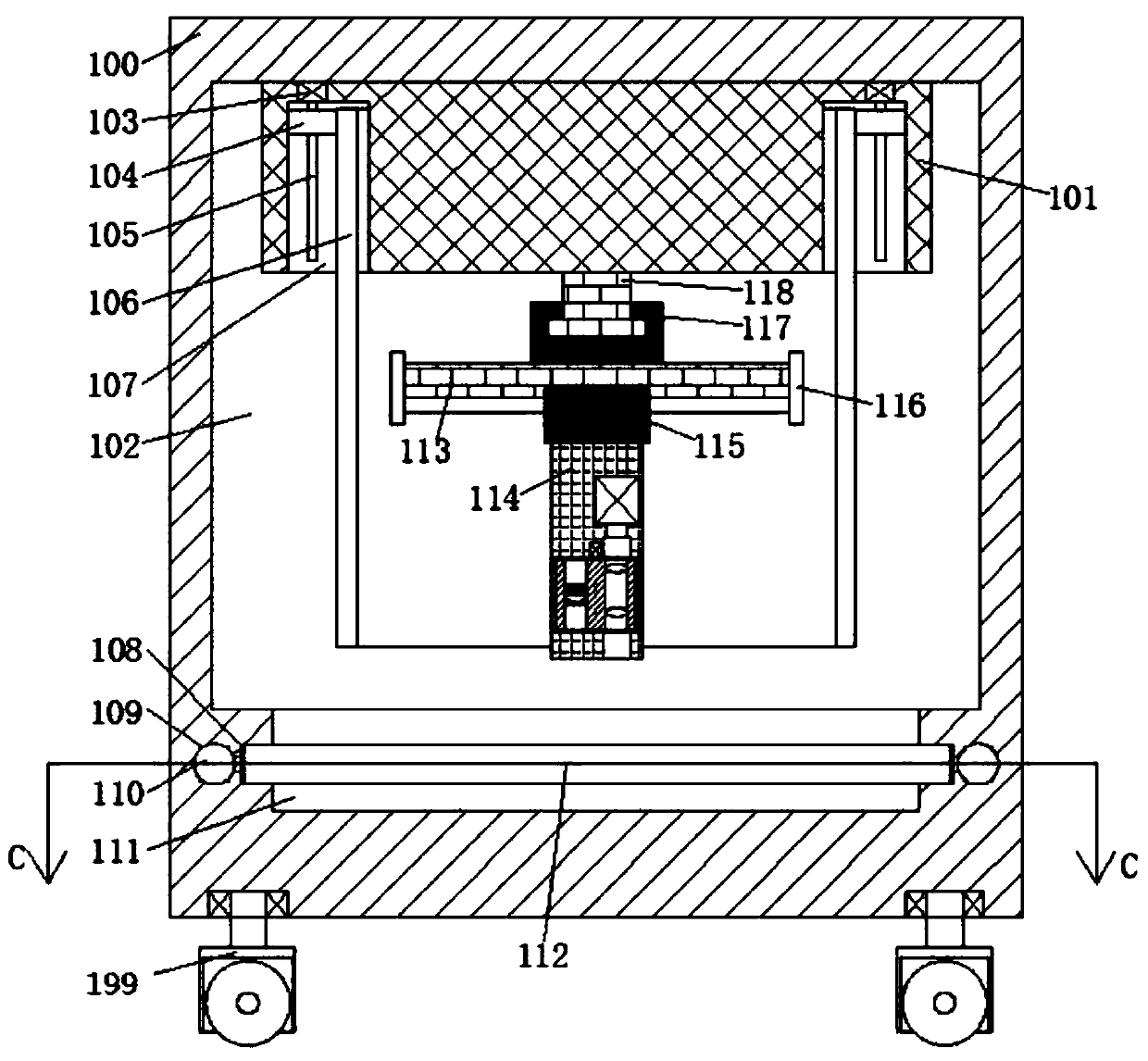

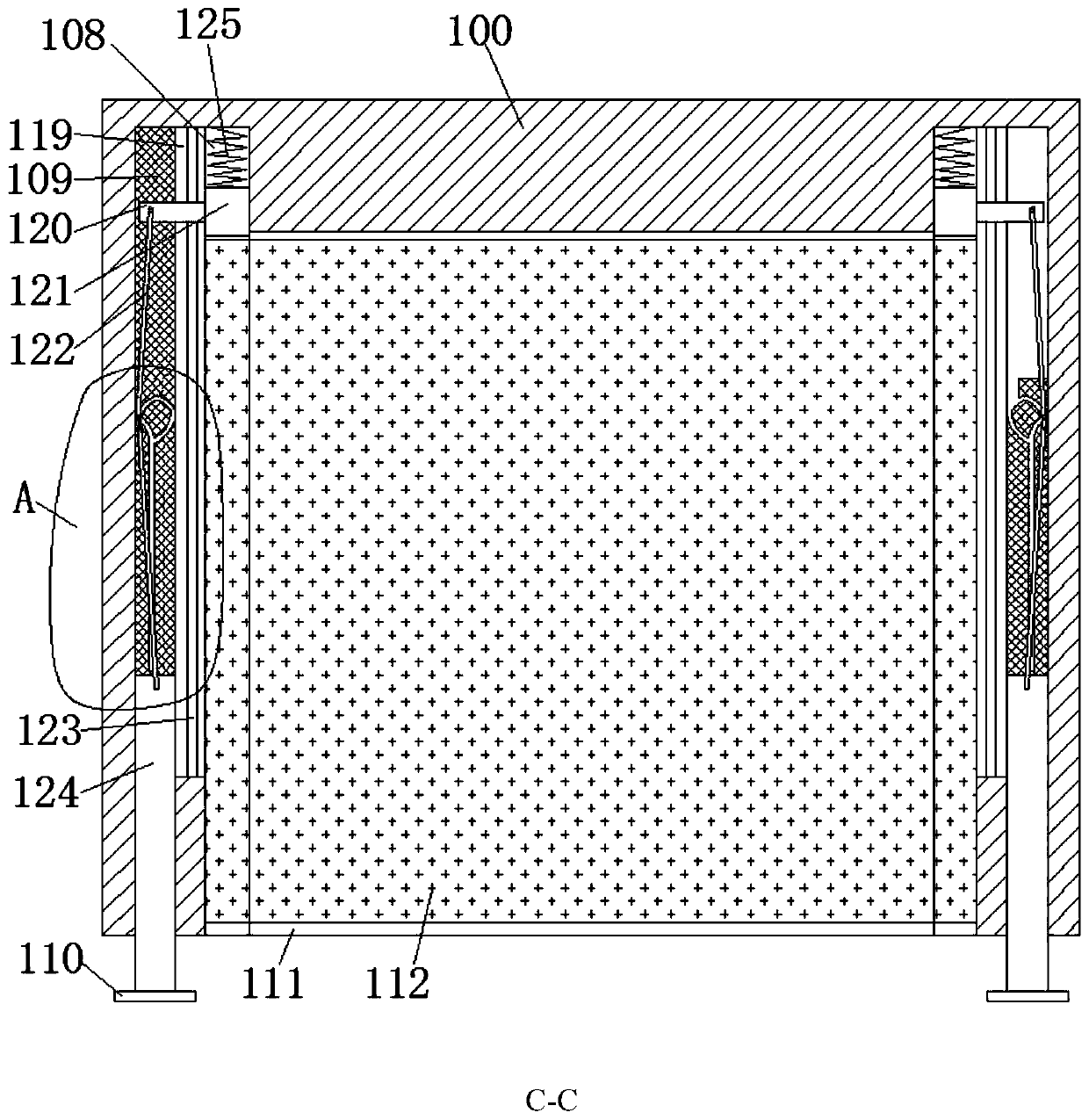

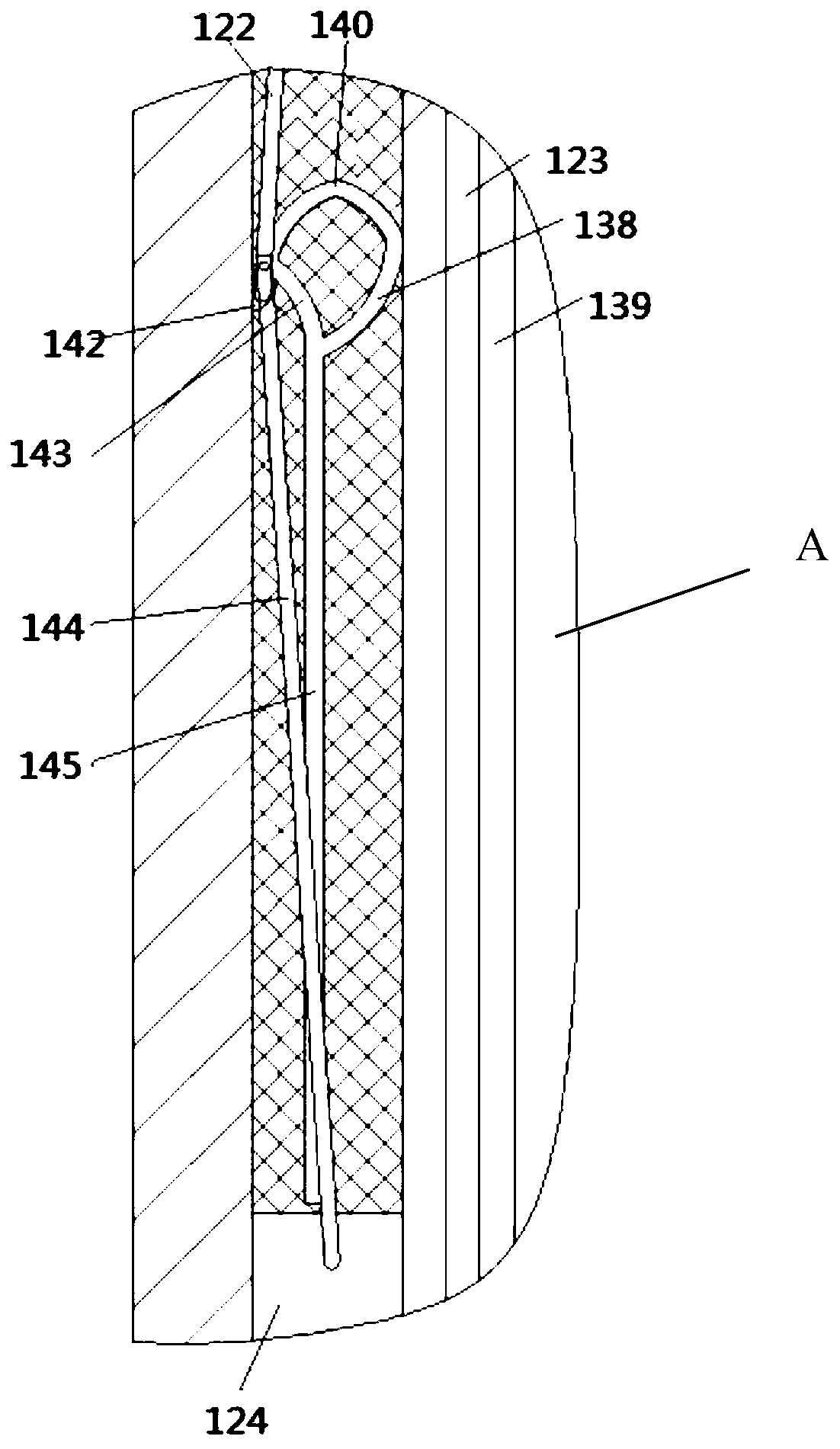

[0032] Convertible internal and external engraving laser equipment of the present invention, such as Figure 1 to Figure 8 As shown, including a working box 100, the working box 100 is provided with a working chamber 102 with an opening forward, and the bottom of the working chamber 102 is connected with a clamping chamber 111 with an opening forward. The moving mechanism, the two-dimensional moving mechanism is provided with a laser emitter 114 . In this embodiment, the two-dimensional moving mechanism includes a forward-backward linear motor and a left-right linear motor connected up and down, and the ceiling body 101 is fixedly connected to the top of the working chamber 102, and the two-dimensional moving mechanism is arranged at the center of the bottom of the ceiling body (101). ; The ceiling body (101) is provided with a workpiece clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com