Cast-rolling coil stripping trolley with elastic support

A technology of elastic support and trolley, which is applied in the field of casting and rolling coil unloading trolley, can solve problems such as scratching the inner ring of the coil, increasing the detection of quality defects, and affecting the quality of the casting and rolling coil surface, so as to prevent crushing and reduce inspection. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

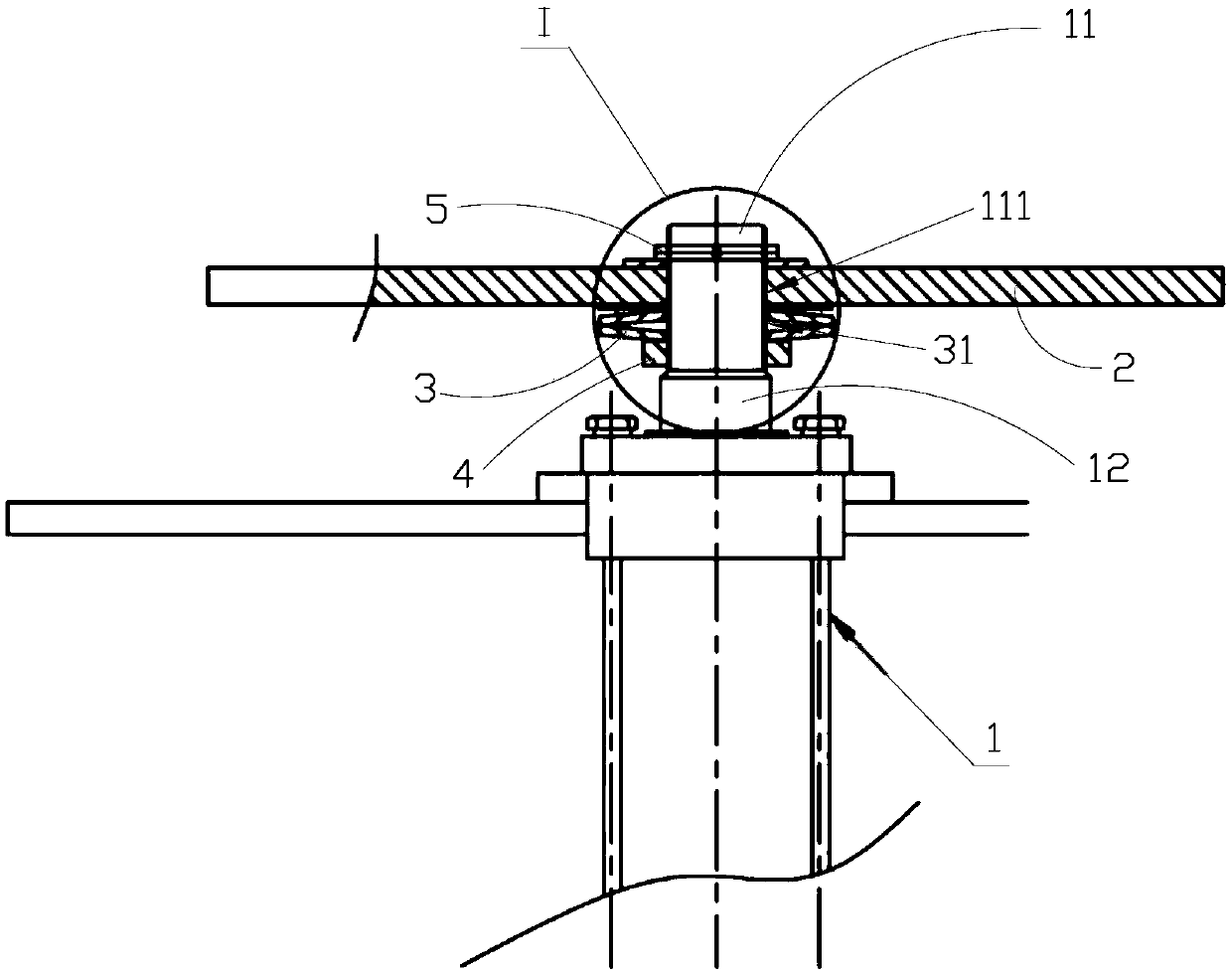

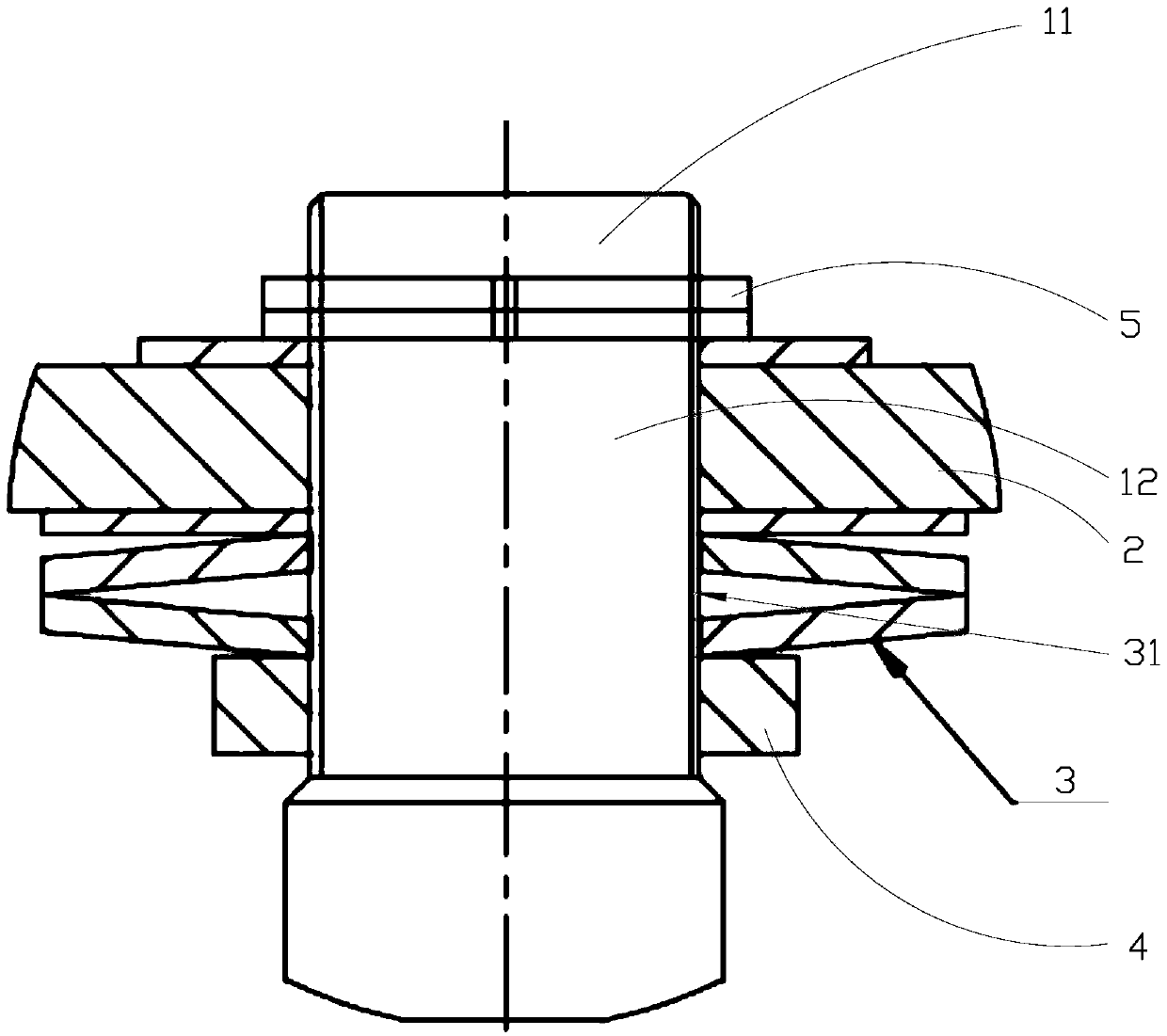

[0022] See attached Figure 1-2 , a casting and rolling unloading trolley with elastic support, comprising: an unloading trolley lifting cylinder 1, an unloading trolley tray 2, an elastic buffer 3 is arranged between the unrolling trolley lifting cylinder 1 and the unloading trolley tray 2.

[0023] The elastic buffer 3 is a disc spring.

[0024] The unloading trolley lift cylinder 1 comprises a piston rod, and the piston rod comprises a connected first rod 11 and a second rod 12, and the diameter of the first rod 11 is smaller than the diameter of the second rod 12;

[0025] The outer wall of the first rod 11 is provided with a connecting thread 111;

[0026] One end of the first bar 11 near the second bar 12 is provided with a support member 4, and the support member 4 is fixedly connected with the first bar 11 through a connecting thread 111; the disc spring is provided with a disc spring mounting hole 31 passing through it, and the disc spring The spring is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com