Parabolic grinding device

A parabola-shaped, grinding technology, applied in the direction of grain processing, etc., can solve the problems of large motor torque, large motor load, damage to the rotating shaft, etc., and achieve the effect of simple structure and sufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

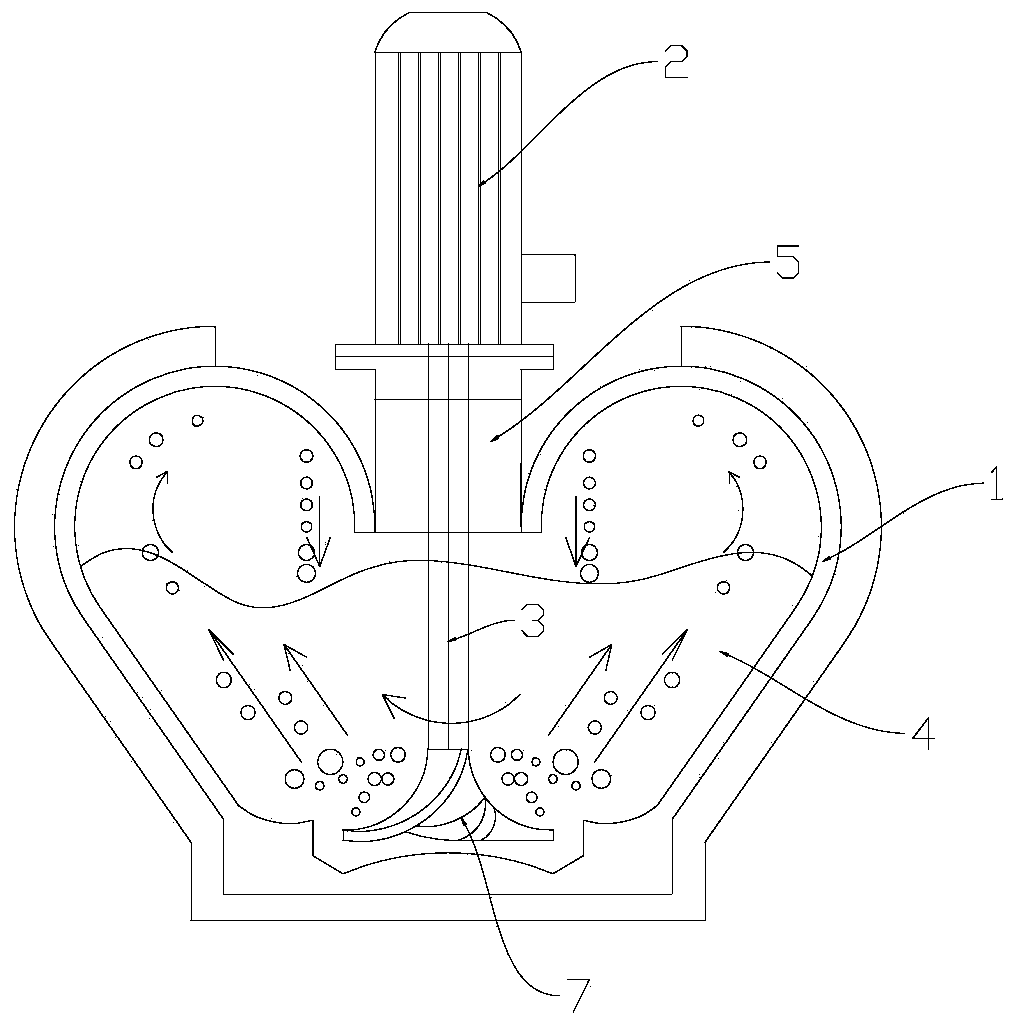

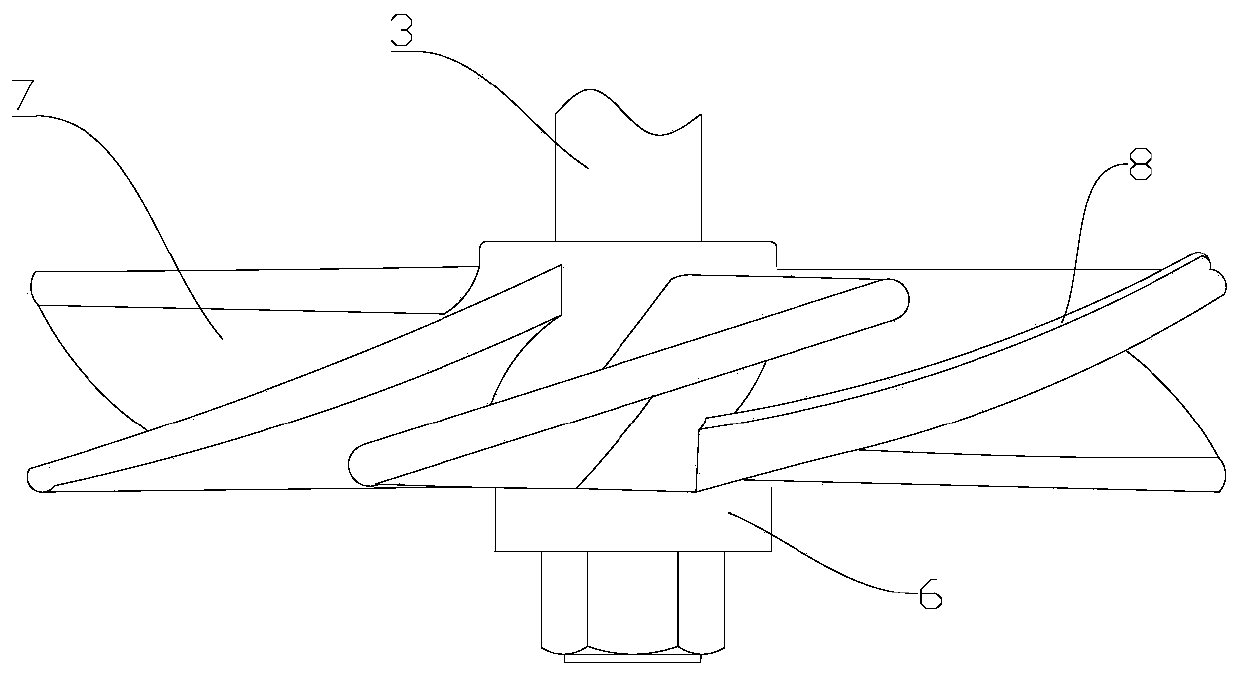

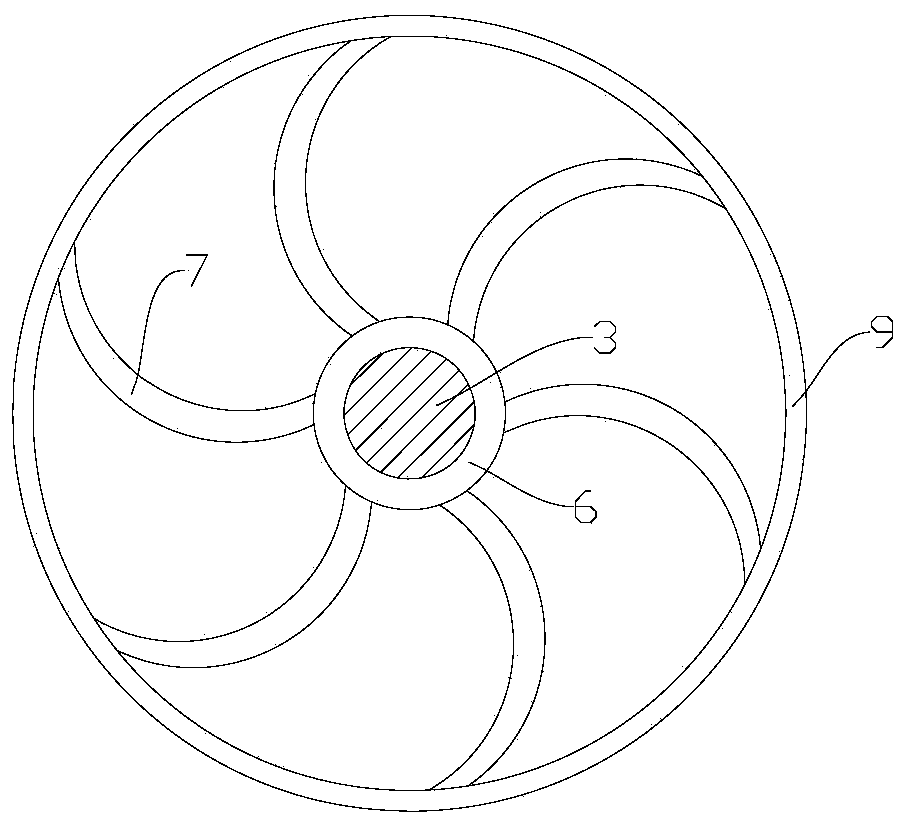

[0027] Please refer to Figure 1 to Figure 3 As shown, the present embodiment provides a parabolic milling device, including a grinding chamber 1, a motor 2 and a rotating shaft 3, the milling chamber 1 has a grinding chamber 4, and the milling chamber 4 has a parabolic parabolic wall surface, and the milling chamber 4 has a parabolic wall. Grinding chamber 4 is filled with granular grinding media. Grinding chamber 1 is provided with a feed inlet and a discharge outlet (not shown in the figure), and a filter screen is provided at the discharge outlet, and the feed inlet is higher than The discharge port and the grinding chamber 4 are made of wear-resistant materials such as wear-resistant alloys. The motor 2 is installed on the top of the grinding chamber 1. The output shaft of the motor 2 is connected to the rotating shaft 3 through a coupling 5, and the rotating shaft 3 extends to the bottom of the grinding chamber 4, the bottom end of the rotating shaft 3 is interference-fi...

Embodiment 2

[0033] Please refer to Figure 1 to Figure 5 As shown, this embodiment provides a parabolic mill, except for having all the technical features in Embodiment 1, the difference lies in that the outer wall of the grinding chamber 1 is provided with a cooling system. The cooling system includes a cooling jacket 10, a power supply 11, a cold water tank 12, a first U-shaped pipe 13 and a second U-shaped pipe 14, and the cold water tank 12 is sealed and connected to the cooling jacket 10 through a water delivery pipe 15. The water pipe 15 is provided with a solenoid valve 16, and the cooling jacket 10 is connected to the cold water tank 12 through the return pipe 17, and the water return pipe 17 is provided with a water pump 18, and the cooling jacket 10 is coated on the outer wall of the grinding chamber 1 to cool The sleeve 10 is made of a material with good thermal conductivity, such as a copper sleeve, an aluminum sleeve, and the like. Two sets of four holes are arranged symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com