Tail gas treatment method and system for DMF wastewater

A technology of wastewater treatment and treatment method, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems that formic acid and odor cannot be effectively removed, and the removal rate of tail gas treatment is not high, and can reduce the odor index and VOCs concentration, enhancement effect, effect of improving air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

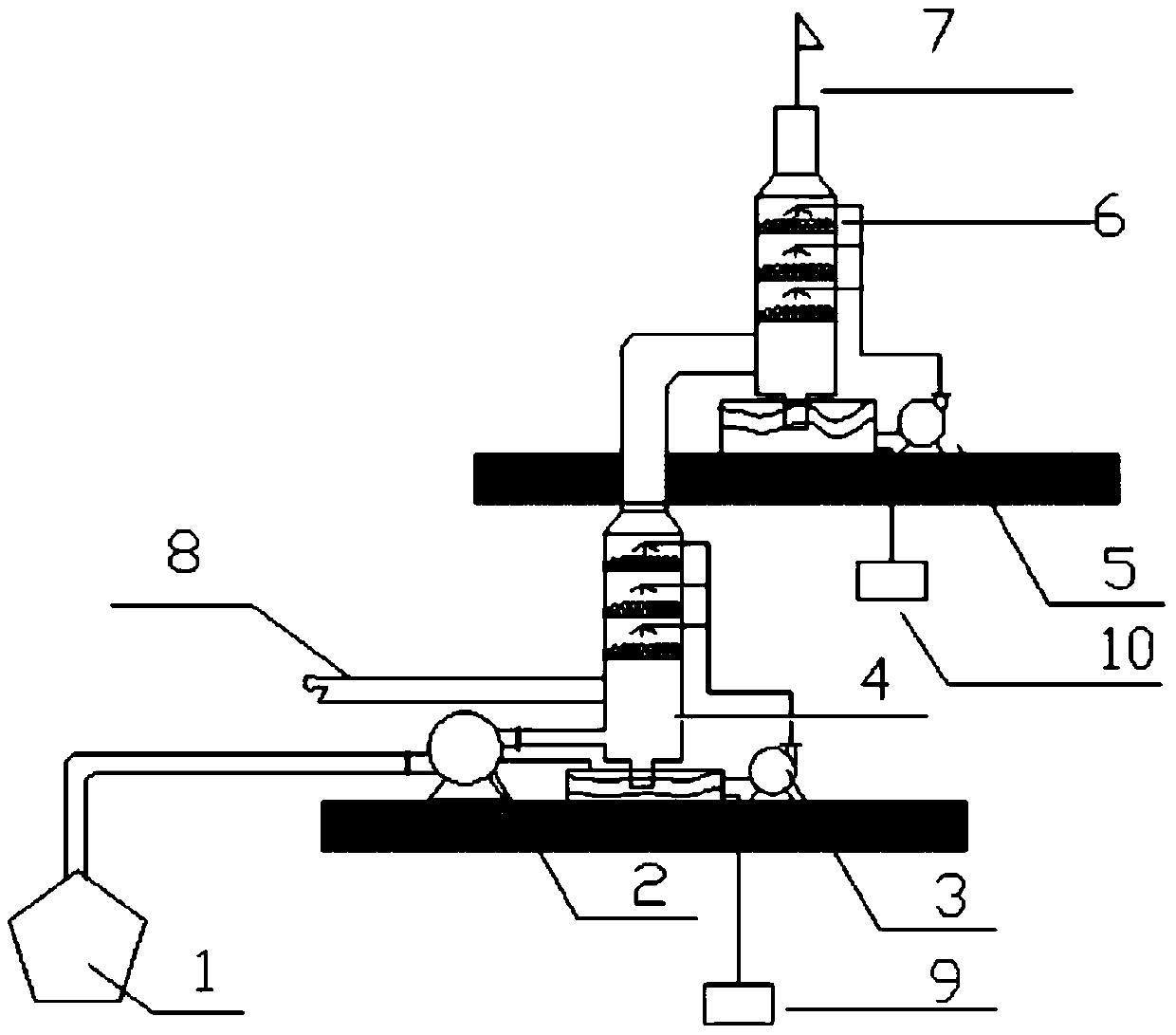

[0029] Such as figure 1 As shown, the present invention provides a kind of comprehensive treatment system for the tail gas that DMF waste water treatment process produces, the tail gas that synthetic leather contains DMF waste water treatment process system to produce is collected and mixed and enters tail gas pickling tower and alkali washing tower successively, and the tail gas in the tail gas is collected and mixed. The dimethylamine and formic acid are fixed in the form of dimethylamine sulfate and formic acid sodium salt respectively, and then concentrated for resource utilization, and the qualified tail gas after washing is discharged into the atmosphere. Specifically include the following plans:

[0030] A treatment system for tail gas generated in DMF wastewater treatment, the generated tail gas is firstly removed by acid wash tower to remove dimethylamine, and then by alkali wash tower to remove formic acid;

[0031] The pickling tower includes a multi-stage packed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com