Green plum processing method for coproducing normal green plum juice and salt-free green plum blanks

A processing method, green plum technology, applied in the confectionary industry, climate change adaptation, confectionery, etc., can solve the problems of long drying time and limited subsequent processing methods of subsequent sugar-containing plum bases, and achieve low pectin content and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

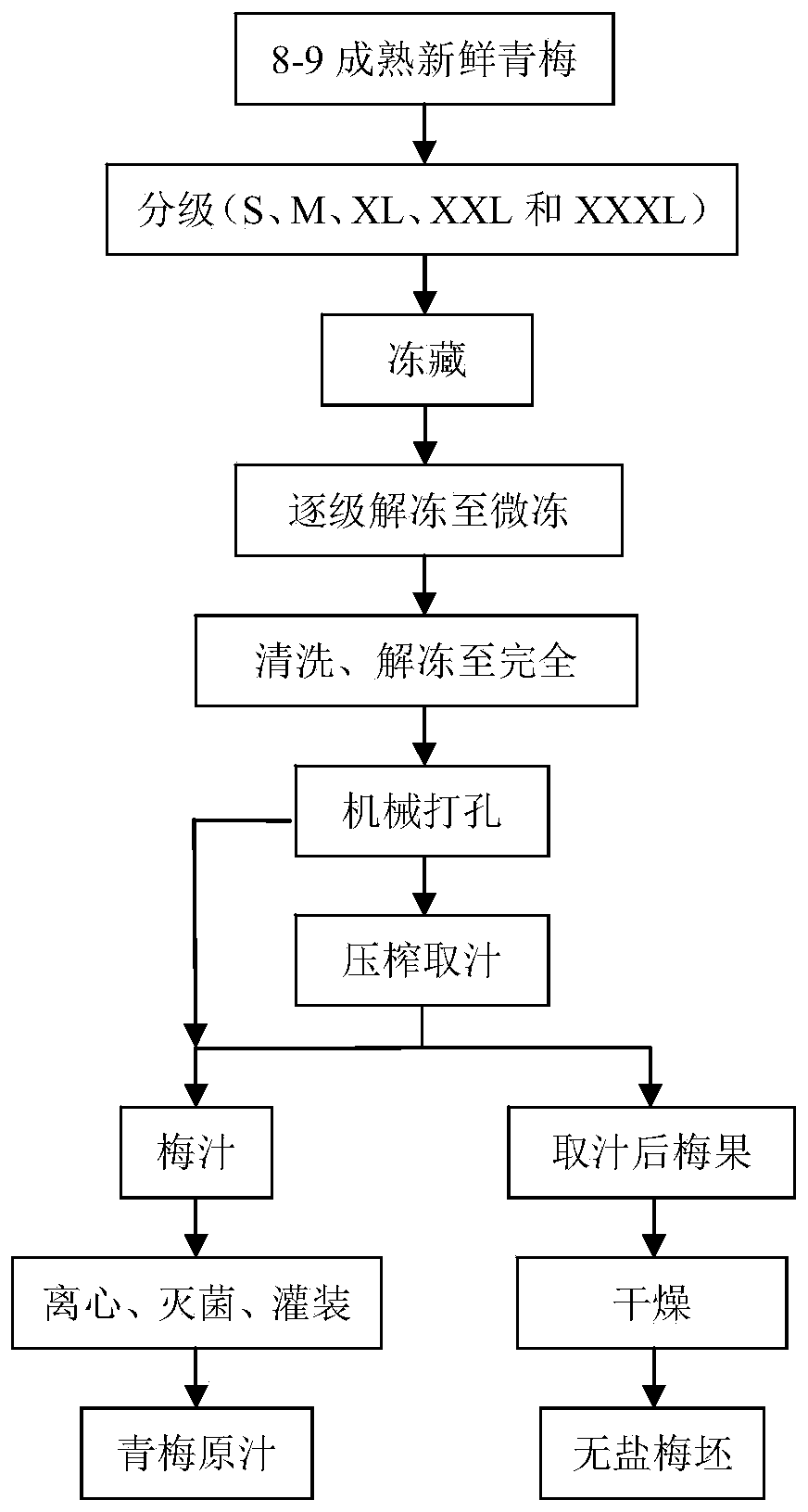

[0033] Such as figure 1 As shown in , the method for utilizing fresh greengage to co-produce greengage juice and unsalted plum base provided by the present embodiment comprises the following steps:

[0034](1) Collect 1 ton of 9 mature fresh greengages, use perforated belt and grid roller grader to grade, and divide them into small (S), medium (M), large (XL), larger (XXL) and extra large (XXXL) There are 5 grades in total, packed in plastic bags of uniform specifications, and then placed in uniform plastic baskets, marked with size and model, transferred to -18°C freezer for storage, until the green plums are completely frozen;

[0035] (2) Transfer completely frozen green plums of different sizes to a 4°C freezer in batches to thaw. It means that there is a little ice slag left on the surface of the greengage, the fruit of the greengage can be separated from each other, and the texture of the greengage is no longer hard;

[0036] (3) Carry out bubbling and cleaning the gre...

Embodiment 2

[0043] Such as figure 1 As shown in , the method for utilizing fresh greengage to co-produce greengage juice and unsalted plum base provided by the present embodiment comprises the following steps:

[0044] (1) Collect 1 ton of 9 mature fresh greengages, use perforated belt and grid roller grader to grade, and divide them into small (S), medium (M), large (XL), larger (XXL) and extra large (XXXL) There are 5 grades in total, packed in plastic bags of uniform specifications, and then placed in uniform plastic baskets, marked with size and model, transferred to -35°C freezer for storage, until the green plums are completely frozen;

[0045] (2) Transfer completely frozen green plums of different sizes to a 4°C freezer in batches to thaw, and when the green plums can be dispersed from each other, transfer to room temperature and continue to thaw to a slightly frozen state;

[0046] (3) Spray and clean the green plum fruit in slightly frozen state;

[0047] (4) air-dry the clean...

Embodiment 3

[0053] Such as figure 1 As shown in , the method for utilizing fresh greengage to co-produce greengage juice and unsalted plum base provided by the present embodiment comprises the following steps:

[0054] (1) Collect 1 ton of 9 mature fresh greengages, use perforated belt and grid roller grader to grade, and divide them into small (S), medium (M), large (XL), larger (XXL) and extra large (XXXL) There are 5 grades in total, put them in plastic bags of uniform specifications, put them in uniform plastic baskets, mark the size and model, and transfer them to -10°C freezer for storage until the green plums are completely frozen;

[0055] (2) Transfer completely frozen green plums of different sizes to a 4°C freezer in batches to thaw, and when the green plums can be dispersed from each other, transfer to room temperature and continue to thaw to a slightly frozen state;

[0056] (3) Spray and clean the green plum fruit in slightly frozen state;

[0057] (4) air-dry the cleaned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com