Anti-warping structure for injection molding piece

An anti-warping, injection molding technology, applied in electrical components, parts of connecting devices, coupling devices, etc., can solve problems such as unfavorable miniaturization design, increase in mounting surface size, seal failure, etc., to reduce the size of the connector. Volume, reducing the volume of injection molded parts, preventing edge warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the technical means and technical effects adopted by the present invention, the present invention will be described in detail below in conjunction with the examples.

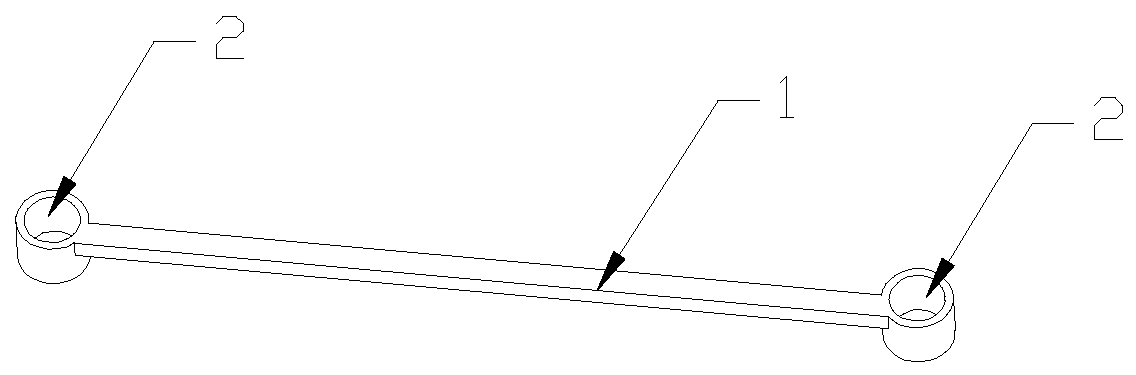

[0020] The anti-warping structure for the injection molded part 3 of the present invention includes a cross bar 1 and through holes I2 arranged at both ends of the cross bar. The through hole I and the cross bar are integrated. The anti-warping structure is made of stainless steel, which is formed as a whole by stamping, and has the characteristics of high hardness and not easy to bend. The surface of the anti-warping structure can also be coated with a layer of coating, which can be nickel-plated layer or zinc-nickel layer or passivation treatment layer to prevent the anti-warping structure from being exposed to the air for a long time or during use The base material is corroded.

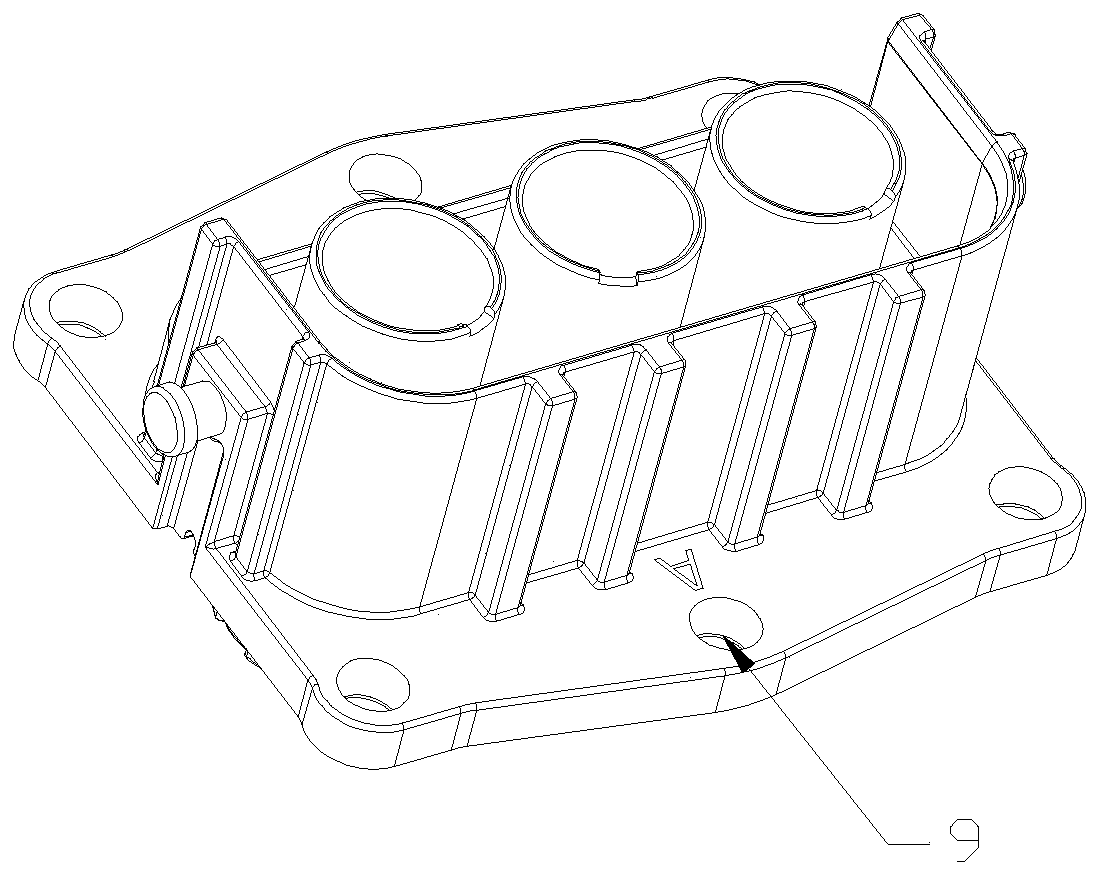

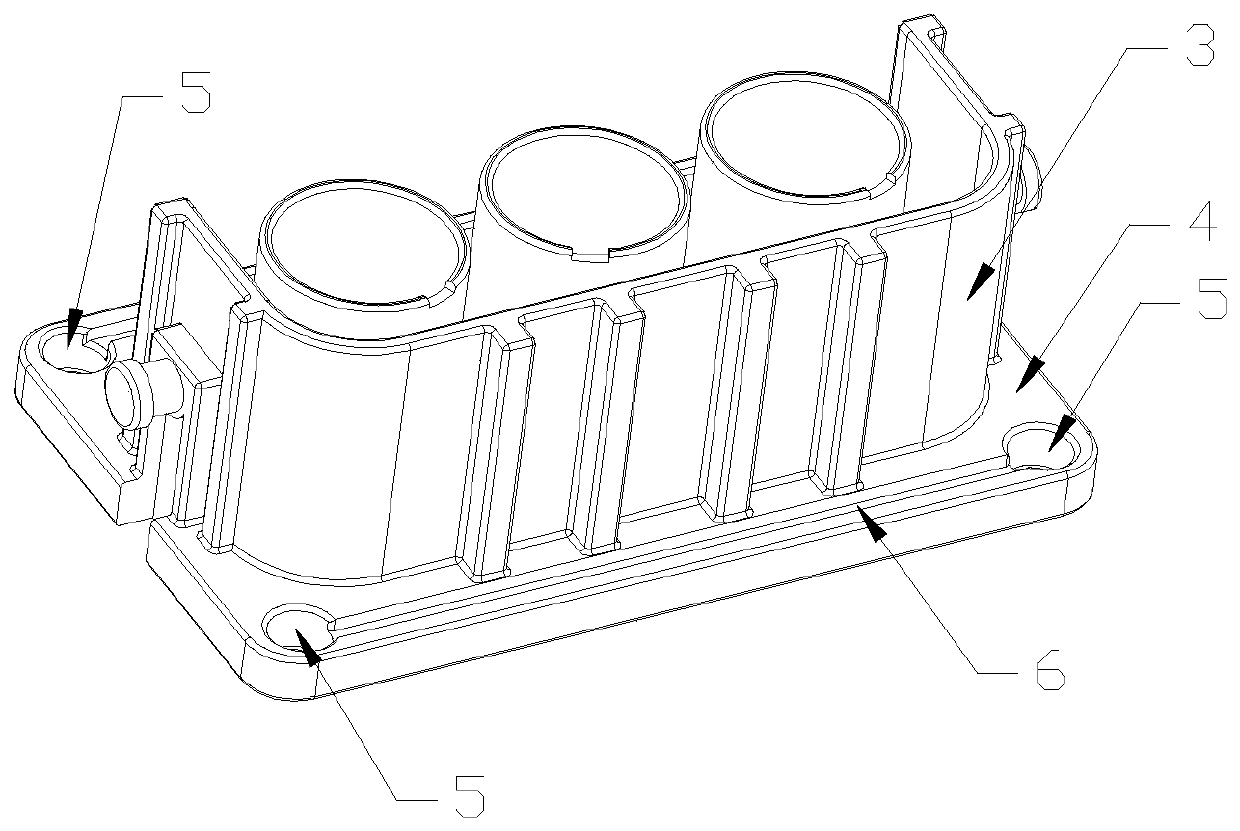

[0021] The injection molded part panel 4 used in conjunction with the anti-warping structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com