Axial surface oil seal used for high-speed motor

A technology of high-speed motors and oil seals, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as grease smoke in bearing chambers, easy-to-burn bearing safety, and V-rings are easy to fall off, etc., to solve arch warping and cost The effect of low cost and no safety hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

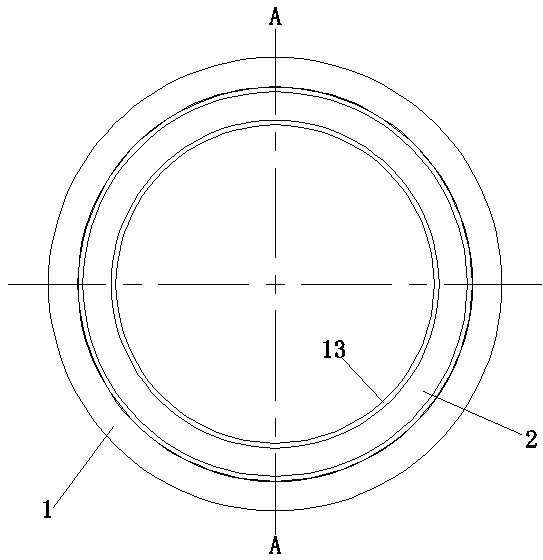

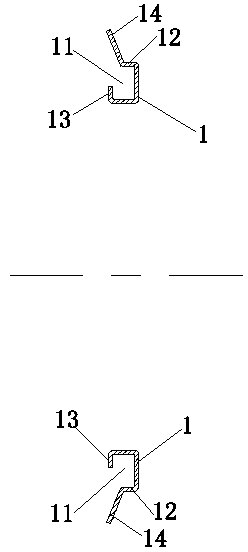

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 The shaft surface oil seal for high-speed motors shown in the figure has a casing shape that is compatible with the motor shaft surface. Its shape is a ring-shaped metal casing (1). The inner diameter of the ring-shaped metal casing matches the motor shaft. Circumferentially arranged grooves (11), the inner diameter of the ring-shaped metal shell extends vertically upward for a period and then extends horizontally outward to form a buckle structure (13), the outer edge of the bottom of the groove is vertically upward extending in one direction to form a vertical groove outer wall (12), and the outer edge of the top of the groove outer wall extends obliquely outward to form the sealing part protection structure (14) of the rubber ring;

[0020] The rubber ring (1) of the oil seal includes a positioning part (22) and a sealing part (21). The positioning part of the rubber ring is in the shape of a ring, and the height...

Embodiment 2

[0022] Such as Figure 5 The shown embodiment 2 is an oil seal for the shaft end face of a high-speed motor. The shape of its shell is adapted to the end face of the motor shaft. The structure of its rubber ring is consistent with that of embodiment 1. The bending mechanism (15), that is, an L-shaped bending structure (15) is provided extending outward from the outer edge of the sealing portion protection structure of the annular metal casing in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com