Flat plate type sander connected to dust collection device

A technology of dust collection device and flat plate, which is applied in the field of sanding machines, can solve the problems of dust environment, human hazards, poor dust collection effect, etc., and achieve the effects of improving the use environment, saving costs, and high dust collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

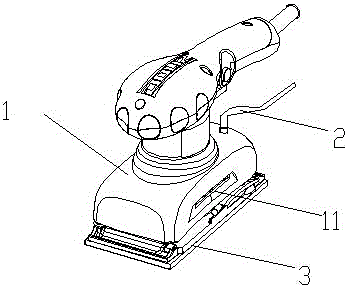

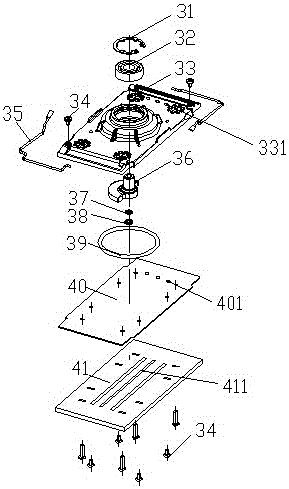

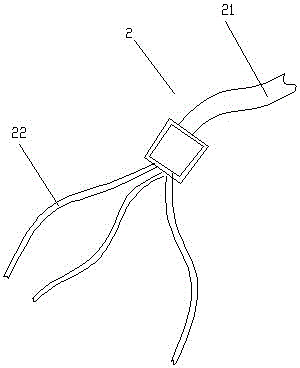

[0026] Such as Figure 1-3 As shown, a flat sand connected with a dust suction device includes a bottom plate assembly 3, a casing 1, a drive assembly and an eccentric assembly located in the casing 1, and the drive assembly drives the bottom plate assembly 3 to swing eccentrically through the eccentric assembly. , the base plate assembly 3 includes a base plate 33 and a base pad 41 arranged up and down, the base pad 41 is provided with a dust removal groove 411, and there are three dust removal grooves 411, and the base plate 33 has a first through hole 331 communicating with the dust removal groove 411, The number of the first through holes 331 is also 3, and the sander also has a gas pipe passing through the first through holes 331 or the end is flush with the bottom of the first through holes 331, and the gas pipe has a main pipe 21 and is connected with the bottom of the first through hole 331. The main pipe 21 communicates with the branch pipes 22 , the number of the bra...

Embodiment 2

[0032] Such as Figure 4 As shown, in Embodiment 2, the strip-shaped dust removal groove 411 is arranged side by side in the floor pad 41 along the length direction of the bottom pad 41, the first through hole 331, the fourth through hole 401 in the bottom plate assembly 3, and the second through hole on the sandpaper. The hole and the third through hole are adjusted accordingly with the change of the position of the dust removal groove 411, and the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

[0034] Such as Figure 5 As shown, in Embodiment 3, the dust removal grooves 411 are arranged in an umbrella-shaped manner in the bottom plate pad 41, the first through hole 331, the fourth through hole 401 in the bottom plate assembly 3, and the second through hole and the third through hole on the sandpaper Corresponding adjustments are made as the position of the dust removal tank 411 changes, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com