An Improved Ribbon Loom with Stable Weft Insertion

A ribbon weaving machine and weft insertion technology, which is applied to looms, small looms, textiles, etc., can solve the problems of pulling out yarn bobbins, hitting nearby operators, and insufficient technical considerations, etc., to achieve increased resistance and improved The effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

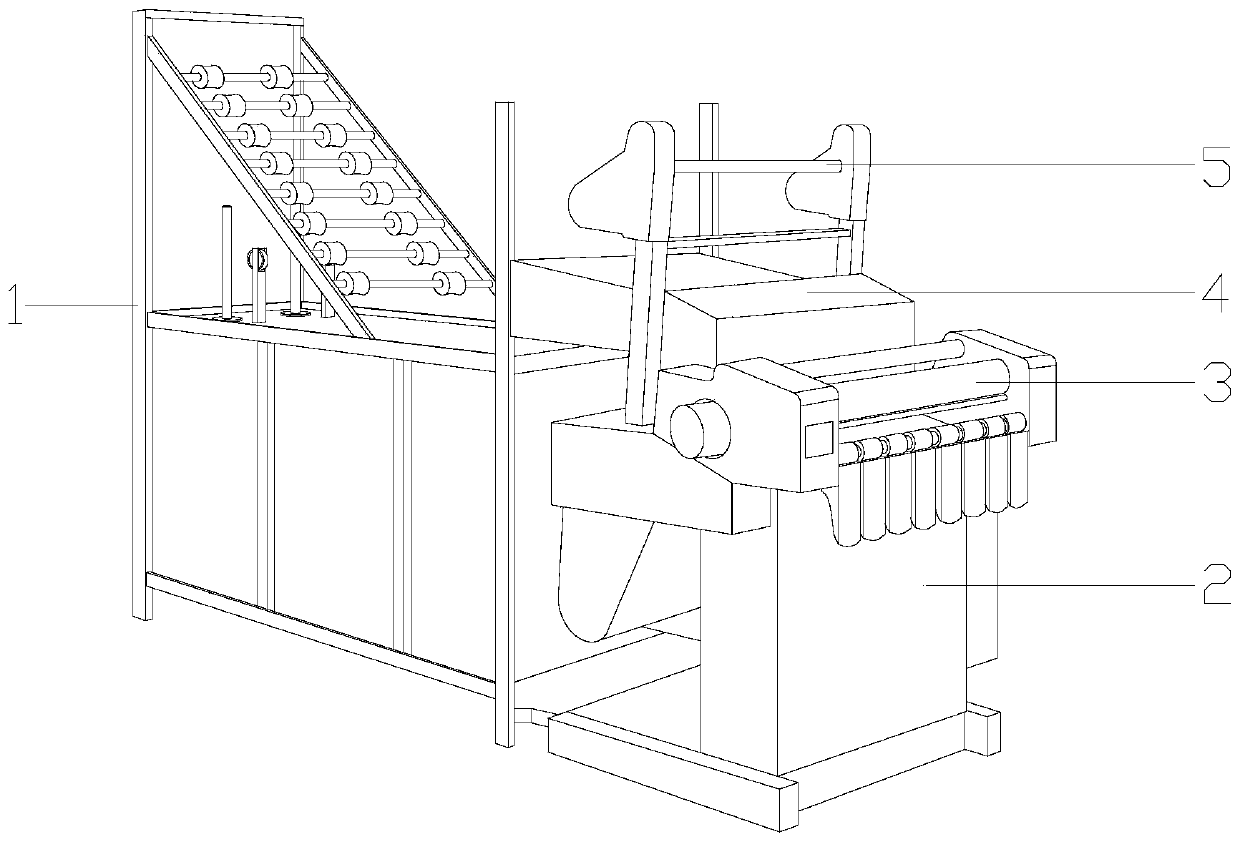

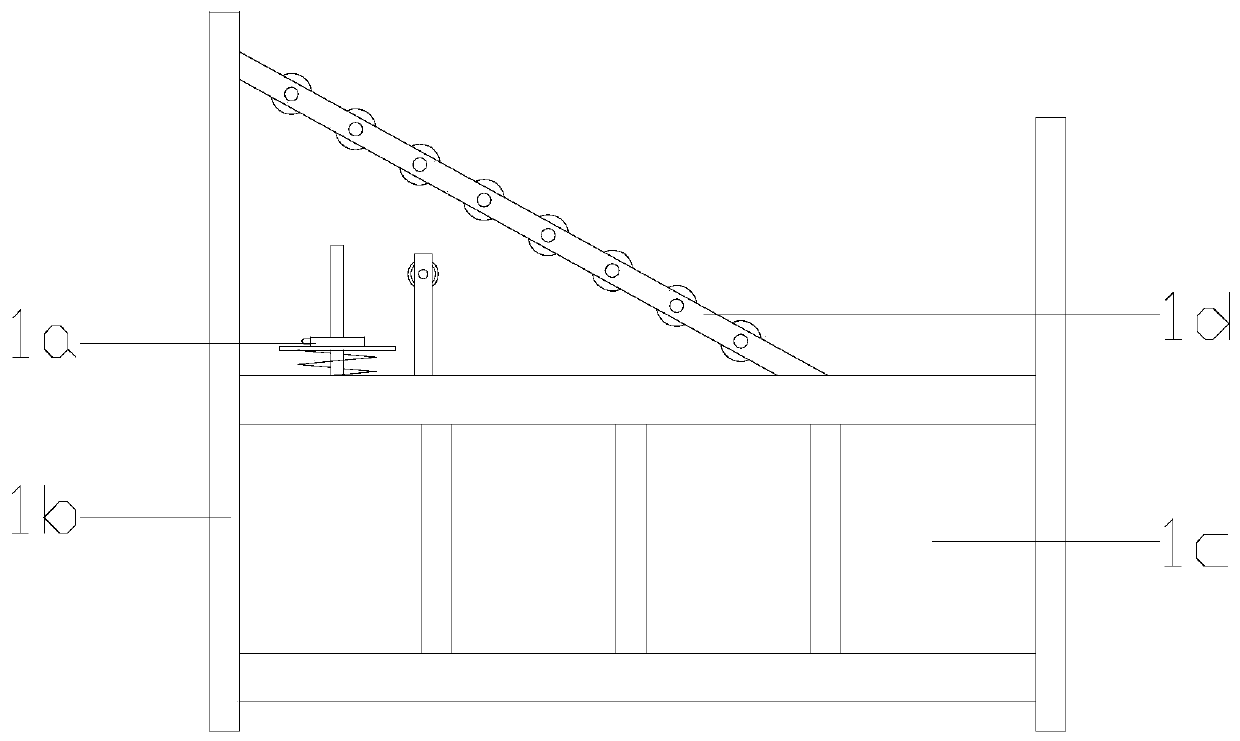

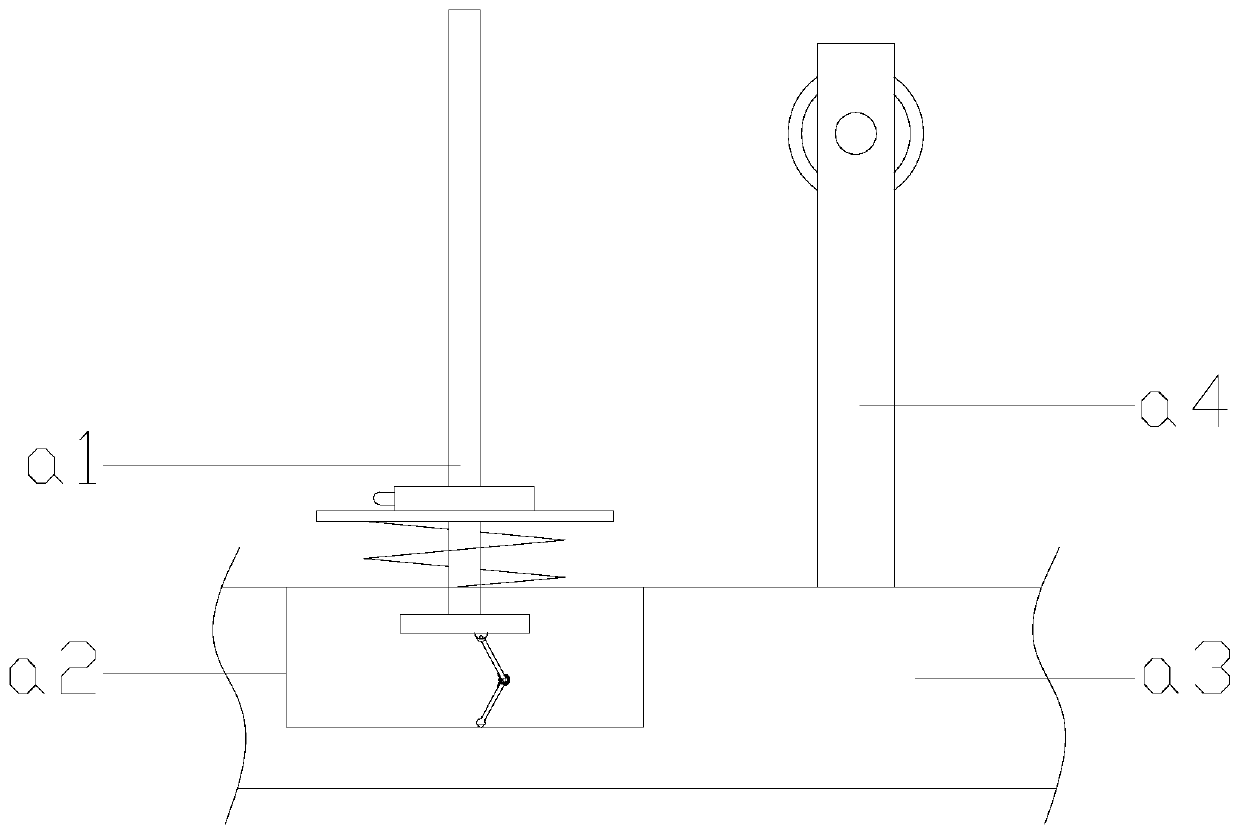

[0031] see Figure 1-Figure 3 , the present invention provides an improved loom for weft insertion, the structure of which includes a pay-off mechanism 1, a loom body 2, a ribbon delivery mechanism 3, a textile mechanism 4, and a directional yarn feeder 5, and the loom body 2 is vertically Installed in the textile workshop, the ribbon conveying mechanism 3 is located at the front top of the ribbon machine main body 2, the textile mechanism 4 is located behind the ribbon conveying mechanism 3 and is mechanically connected to the ribbon conveying mechanism 3, and the bottom of the directional yarn feeder 5 is connected to the textile The left and right sides of the mechanism 4 are fixed together by bolts. The pay-off mechanism 1 is located on the left side of the main body 2 of the loom. The thread guide roller 1d is composed of the right end of the three-dimensional fixed frame 1b and the main body of the loom 2 through bolts. Below the bobbin holder 1a inside the frame 1b, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com