A kind of photocurable 3D printing resin material and preparation method thereof

A technology of 3D printing and resin materials, applied in the direction of additive processing, etc., can solve the problems affecting the dimensional accuracy and surface state of cured materials, the reduction of material performance and stability, and the difficulty of releasing internal stress, etc., to improve printing efficiency, Effects of reduced volume shrinkage and improved tensile strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Correspondingly, the present invention also provides a method for preparing the photocurable 3D printing resin material described in the above technical solution, which comprises the following steps in parts by weight: mixing 1-10 parts of polyvinyl butyral and 30-70 parts Mix the active diluent at room temperature, heat to 50-80°C, keep it warm for 30-90 minutes, then stir at high speed for 30-60 minutes at room temperature to obtain a mixed solution; add 20-50 parts of acrylate, 1- 10 parts of free radical photoinitiator and 0.5-5 parts of additives, stirred at high speed for 60-90 minutes, after being uniformly dispersed, ultrasonically oscillated until defoaming, and a light-cured 3D printing resin material was obtained.

[0026] As a preferred solution, the polyvinyl butyral is preferably 3-7 parts, and the reactive diluent is preferably 40-60 parts. In the step of obtaining the mixed solution, the heating temperature is preferably 70° C.; the time for standing at ...

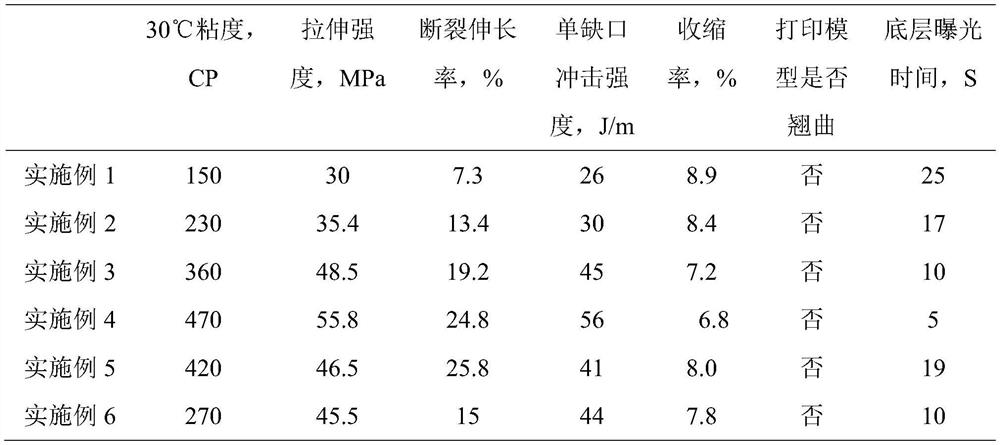

Embodiment 1-6

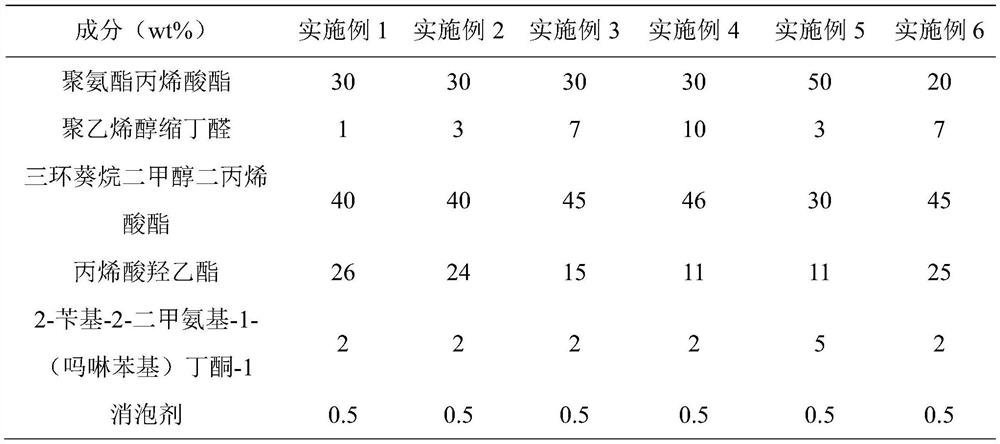

[0032] A photocurable 3D printing resin material based on digital projection technology, which is composed of polyurethane acrylate, polyvinyl butyral, tricyclodecane dimethanol diacrylate, hydroxyethyl acrylate, bis(2,4,6- Trimethylbenzoyl) phenyl phosphine oxide, defoamer, leveling agent mixed. Wherein each raw material and its weight percentage are shown in Table 1.

[0033] The preparation method of described photocuring 3D printing resin material comprises the following steps:

[0034] (1) Take polyvinyl butyral and tricyclodecane dimethanol diacrylate respectively, mix them at room temperature, heat to 70°C, keep the temperature for 60 minutes, and then stir at room temperature for 60 minutes at high speed to obtain a transparent and uniform liquid.

[0035](2) Add polyurethane acrylate, hydroxyethyl acrylate, 2-benzyl-2-dimethylamino-1-(morpholine phenyl) butanone-1, defoamer, leveling agent in the obtained liquid, After mixing at room temperature, stir at a high spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com