High-precision battery discharge management system

A battery discharge and management system technology, applied in battery circuit devices, secondary batteries, secondary battery testing, etc., can solve problems such as hidden safety hazards in battery use, achieve the effect of avoiding dangerous situations and realizing detection and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

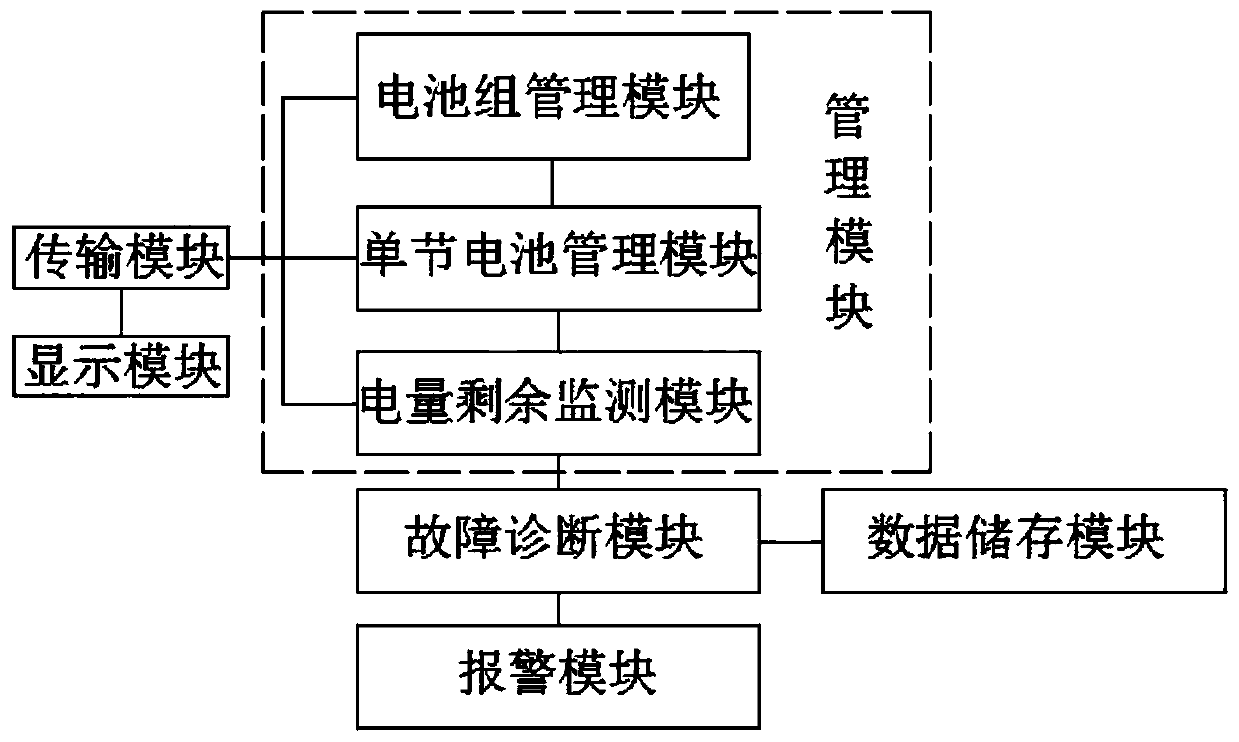

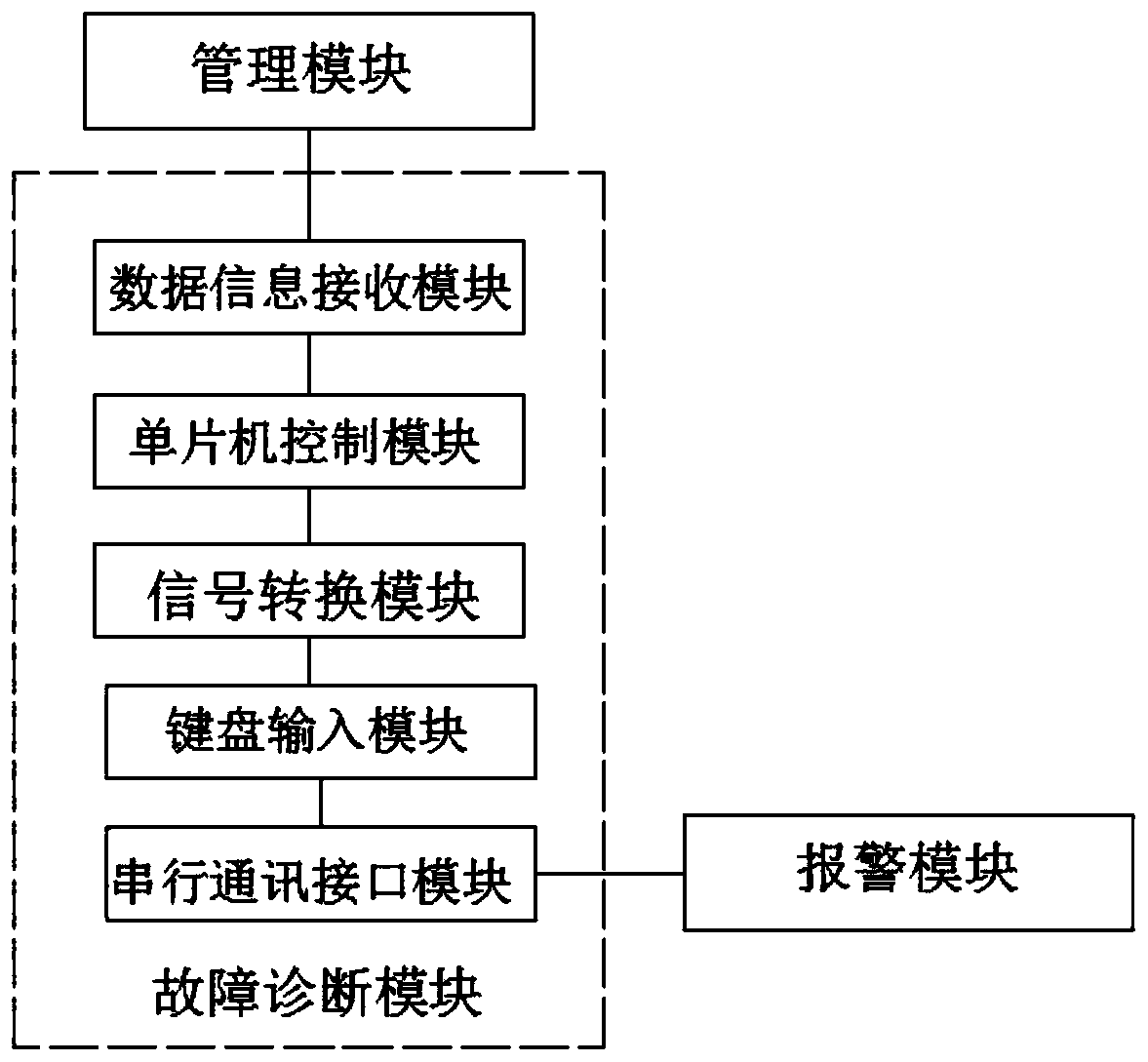

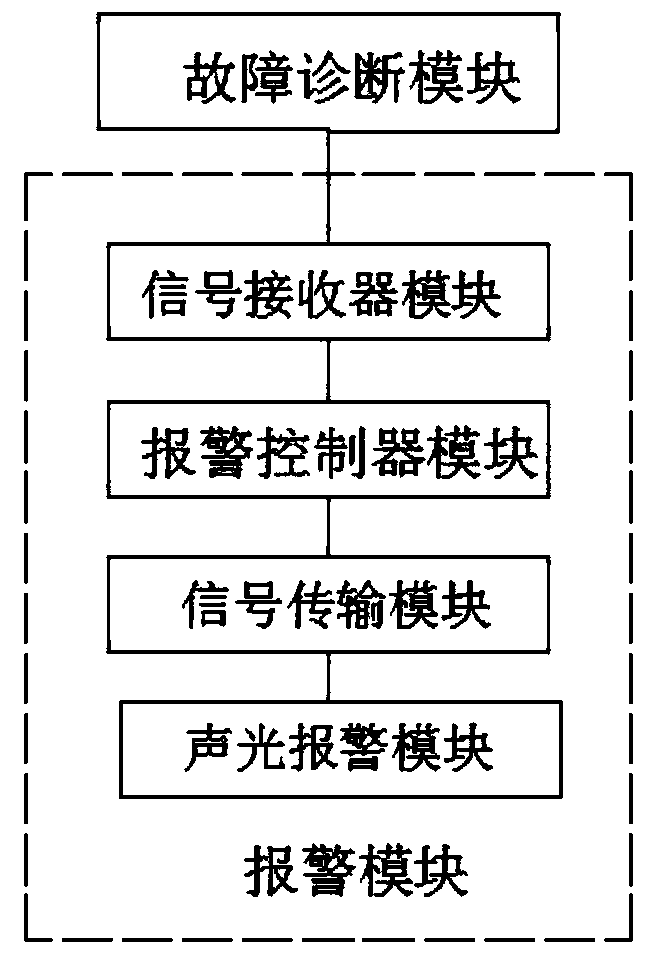

[0023] refer to Figure 1-5 , a high-precision battery discharge management system, including a management module, the management module realizes the signal connection with the display module through the transmission module, and at the same time, the signal connection of the management module is connected with a fault diagnosis module, and the battery is monitored through the fault diagnosis module, and the fault diagnosis module Including the data signal receiving module, the data signal receiving module receives the data monitored in the management module in real time, and transmits the received signal to the single-chip control module for calculation, and passes the calculated data signal through the signal conversion module to make the optical signal conversion It is an electrical signal and transmitted to the keyboard input module, while the keyboard input module is connected to the serial communication interface module, the fault diagnosis module is also connected to the ...

Embodiment 2

[0028] refer to Figure 6-7 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the management module specifically includes a battery pack management module, a single-cell battery management module, and a power remaining monitoring module, and the battery pack management module includes a dynamic voltage detector module, The dynamic current detector module and the dynamic temperature sensor module, the dynamic voltage detector module detects the voltage of the battery pack module, the dynamic current detector module monitors the current of the battery pack, and the dynamic temperature sensor module monitors the temperature of the battery pack module , and the dynamic voltage detector module, dynamic current detector module and dynamic temperature sensor module are all connected to the transmission module through the data signal transmitter module, and the single-cell battery management module specifically includes the dynamic vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com