Instant noodle cake detection system and detection method

A detection system and instant noodle technology, which are used in measuring devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of unguaranteed quality, high labor costs, oil pollution, etc. The detection effect is good, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

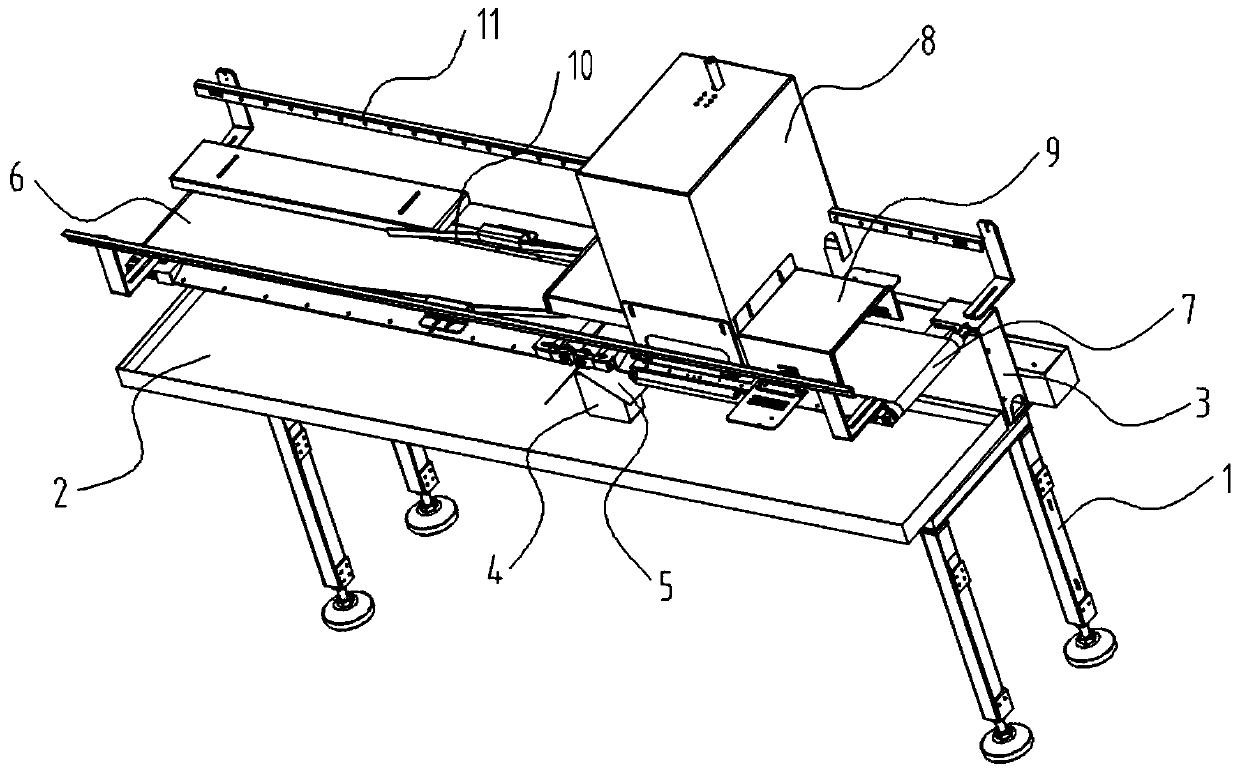

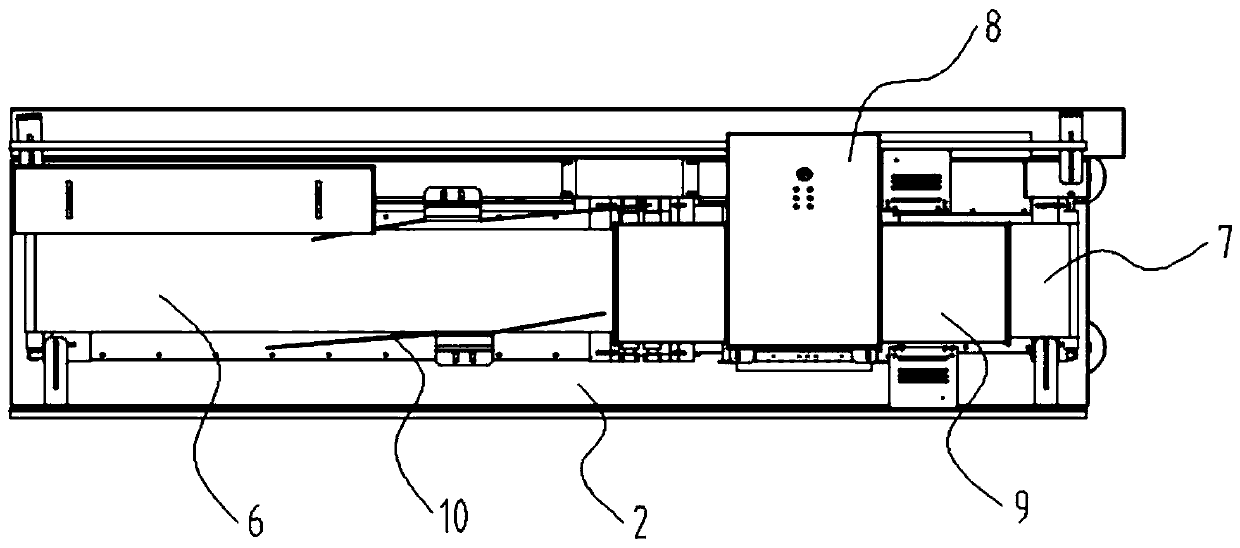

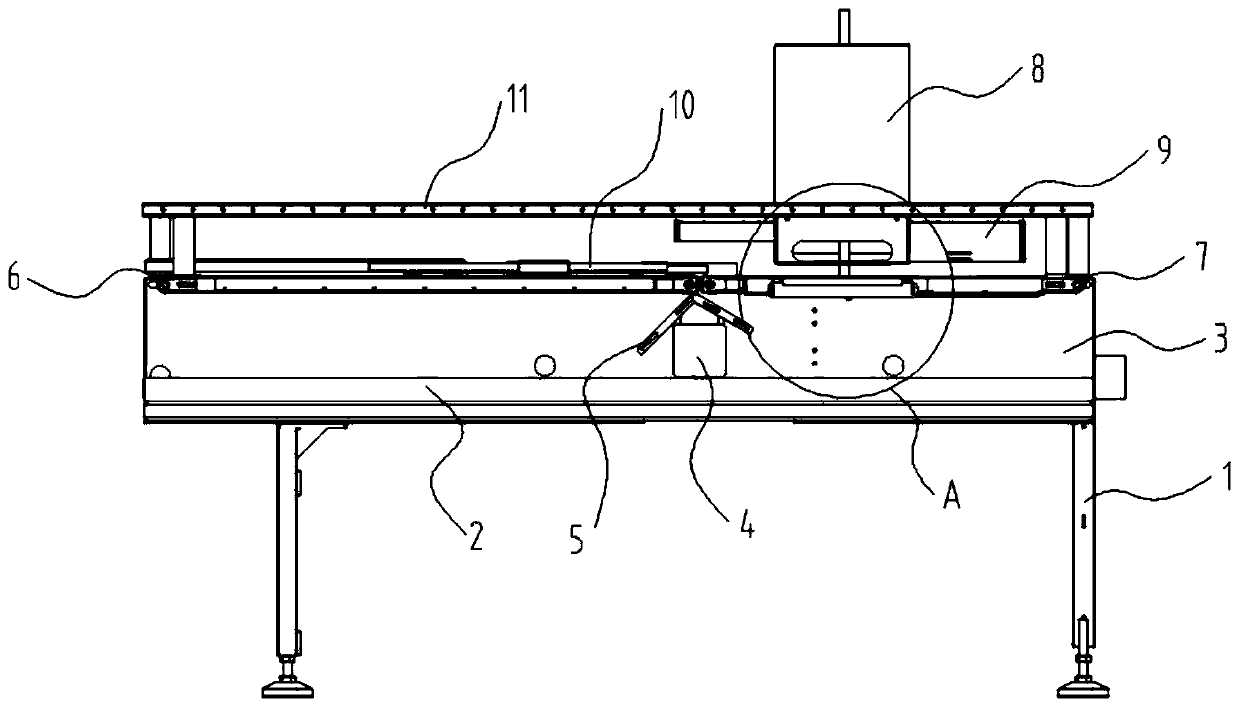

[0069] Such as Figure 1-Figure 3 Shown, a kind of instant noodles noodle detection system comprises the conveying mechanism of the transmission noodle cake installed on the frame: 1 and the camera inspection assembly 8 of detection noodle cake, and said camera inspection assembly 8 comprises the industrial camera 804 of photographing noodle cake And the surface light source 807 that illuminates the bread.

[0070] It can accurately detect defects such as surface oil stains, deep-fried black spots, sandwiched noodles, and severely damaged noodle cakes, and can realize data statistics. The detection speed matches the customer's production line at 140 pieces / minute, and can be adjusted up to 200 pieces / minute. The detection efficiency is high. Reduced labor cost input.

[0071] In one of the examples, as Figure 1-Figure 3 As shown, the conveying mechanism includes a conveying section 6 and a detection section 7, the camera detection assembly 8 corresponds to the position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com