Light-gauge steel joist partition wall with stone-plastic wallboards

A light steel keel and wall panel technology, applied in the field of architectural decoration, can solve problems such as complex construction procedures, insufficient rigidity, and environmental pollution, and achieve the effects of compact structure, improved sound insulation performance, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

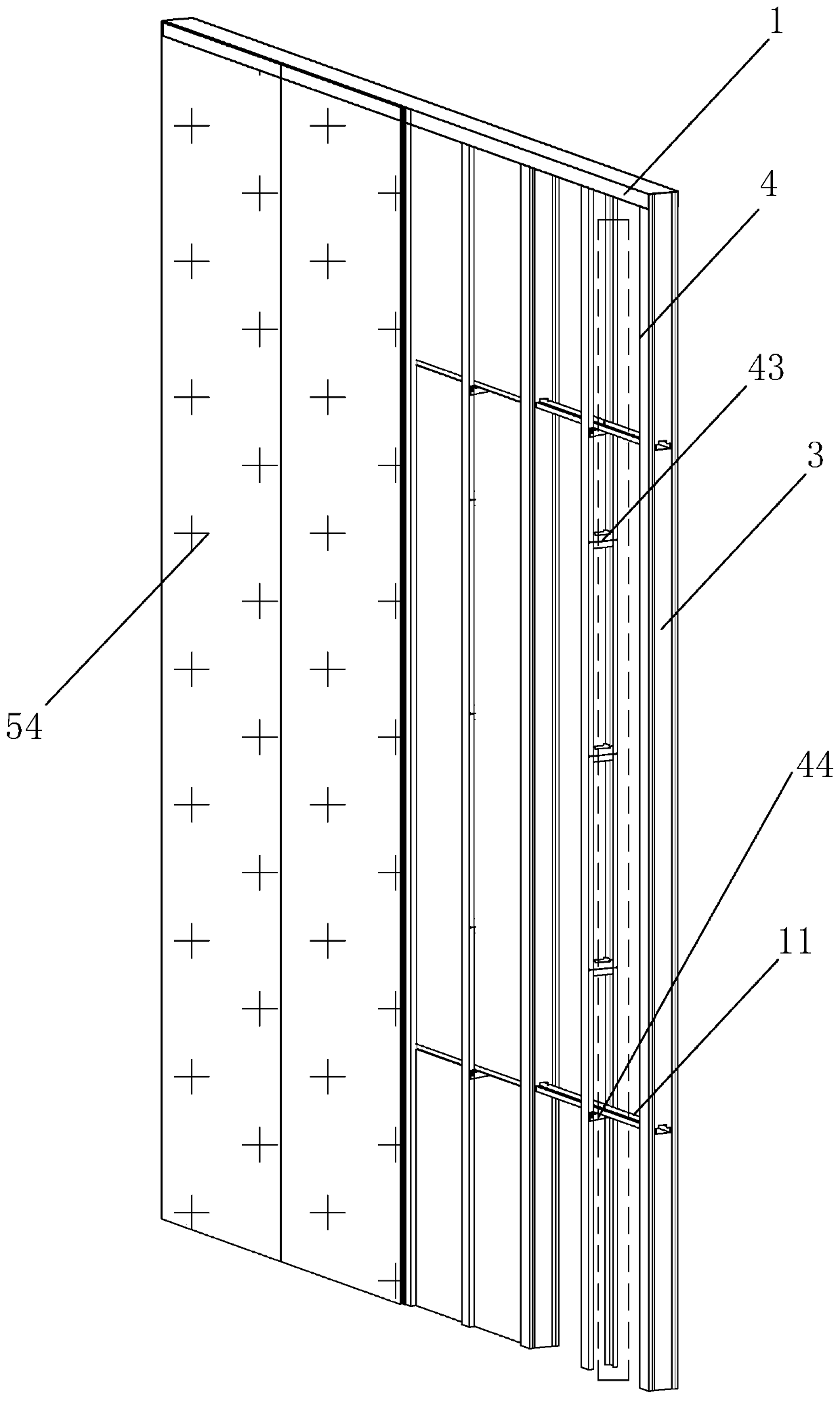

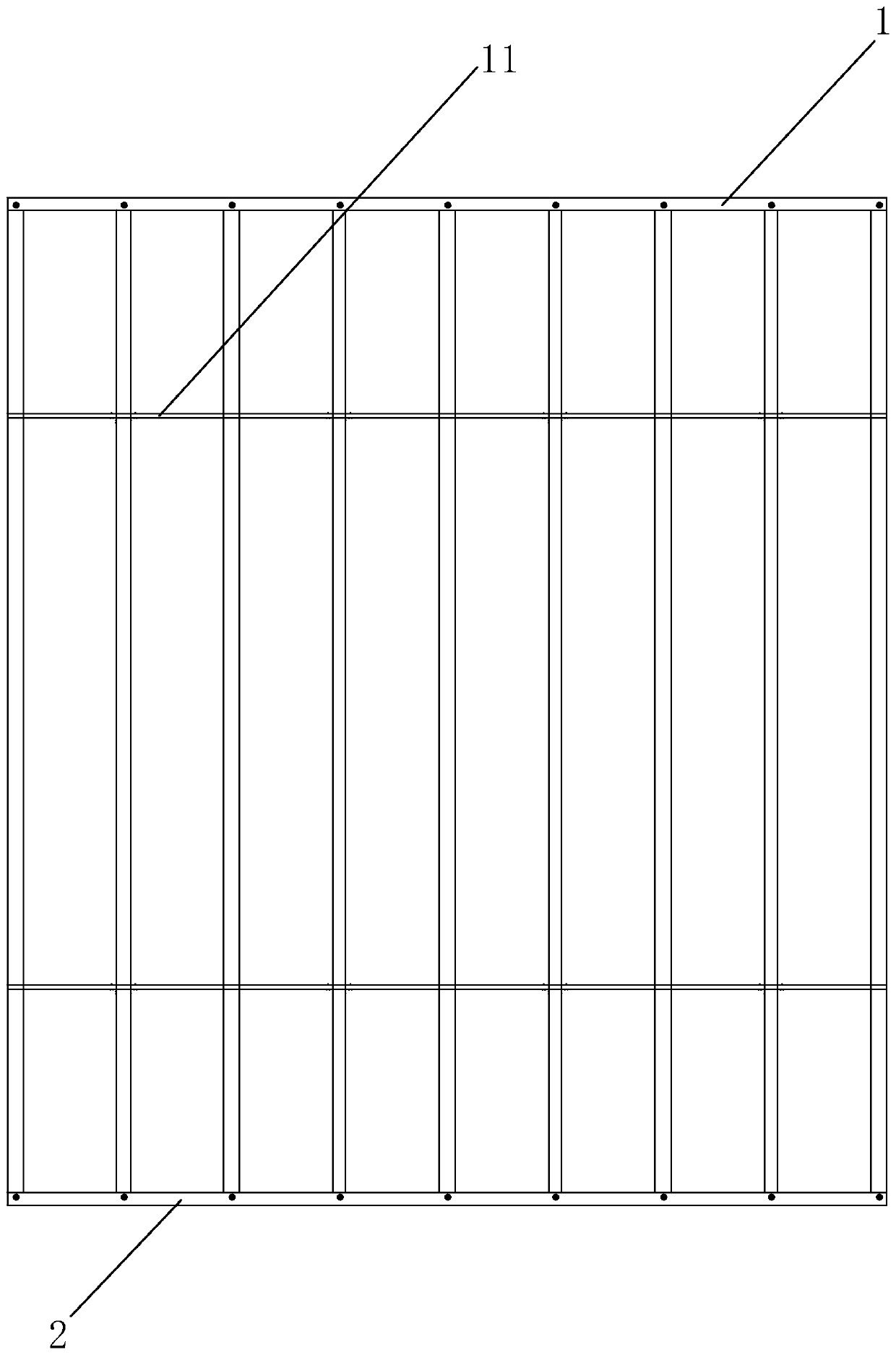

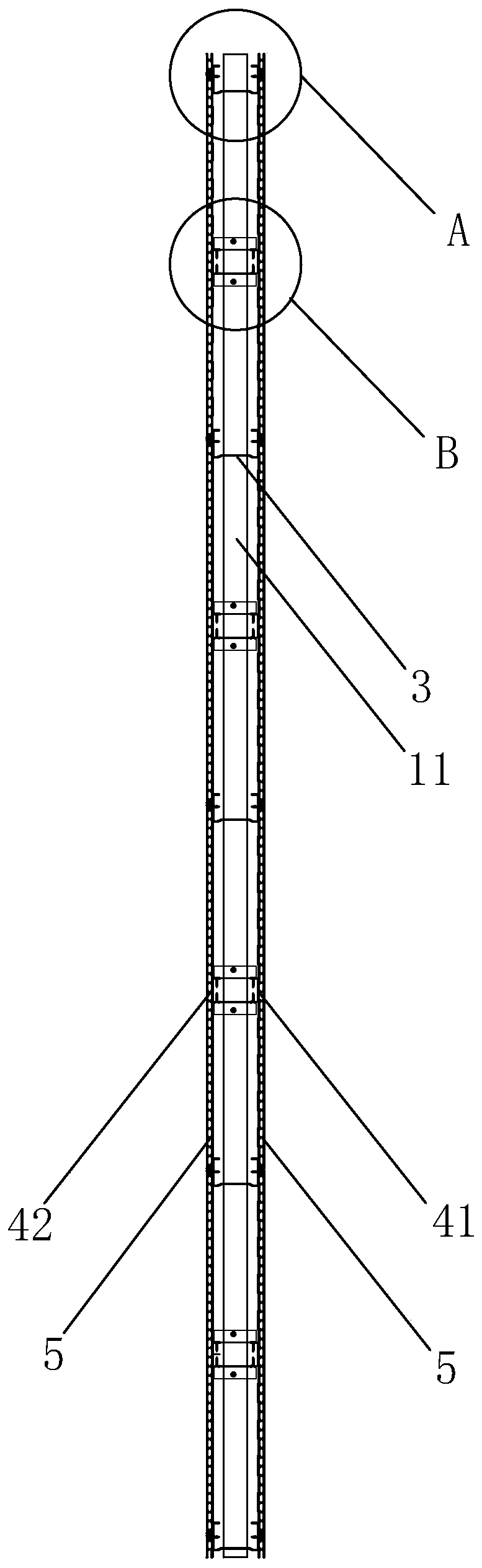

[0026] Such as figure 1 , 2As shown, a stone-plastic wallboard light steel keel partition wall includes a top keel 1 and a ground keel 2, and a number of connected vertical keels 3 are uniformly arranged between the top keel 1 and the ground keel 2. A truncated sound bridge vertical keel group 4 is arranged between the adjacent connected vertical keels 3, and a porous stone-plastic wallboard 5 is arranged on the outside of the cut-off sound bridge vertical keel group 4, and the porous stone-plastic wallboard 5 and the Connected vertical keel 3 connection. The top keel 1 and the ground keel 2 are respectively fixed on the ceiling and the floor to position the partition wall as a whole. The connected vertical keel 3 is the main support component of the light steel keel partition wall. 1 is connected with the keel 2 along the ground, the connected vertical keels 3 are evenly arranged with a spacing of 600mm, and the middle position between the two connected vertical keels 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com