Anti-skid drill cast-in-place pile foundation in high-sensitivity soft soil area and construction method thereof

A bored pile, a high-sensitivity technology, applied in the field of bored pile foundation, can solve the problem of slippage of the underwater anti-slip bored pile foundation, failure of underwater bored piles to form piles, underwater piles Construction platform collapse and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

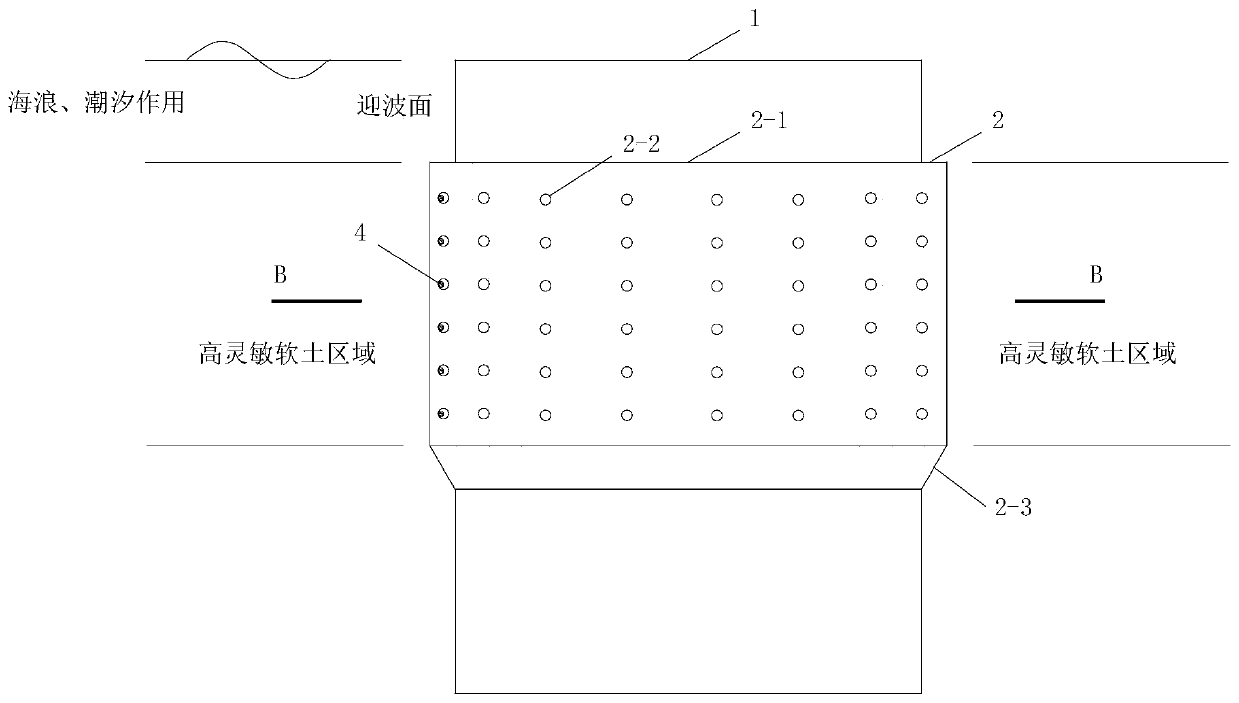

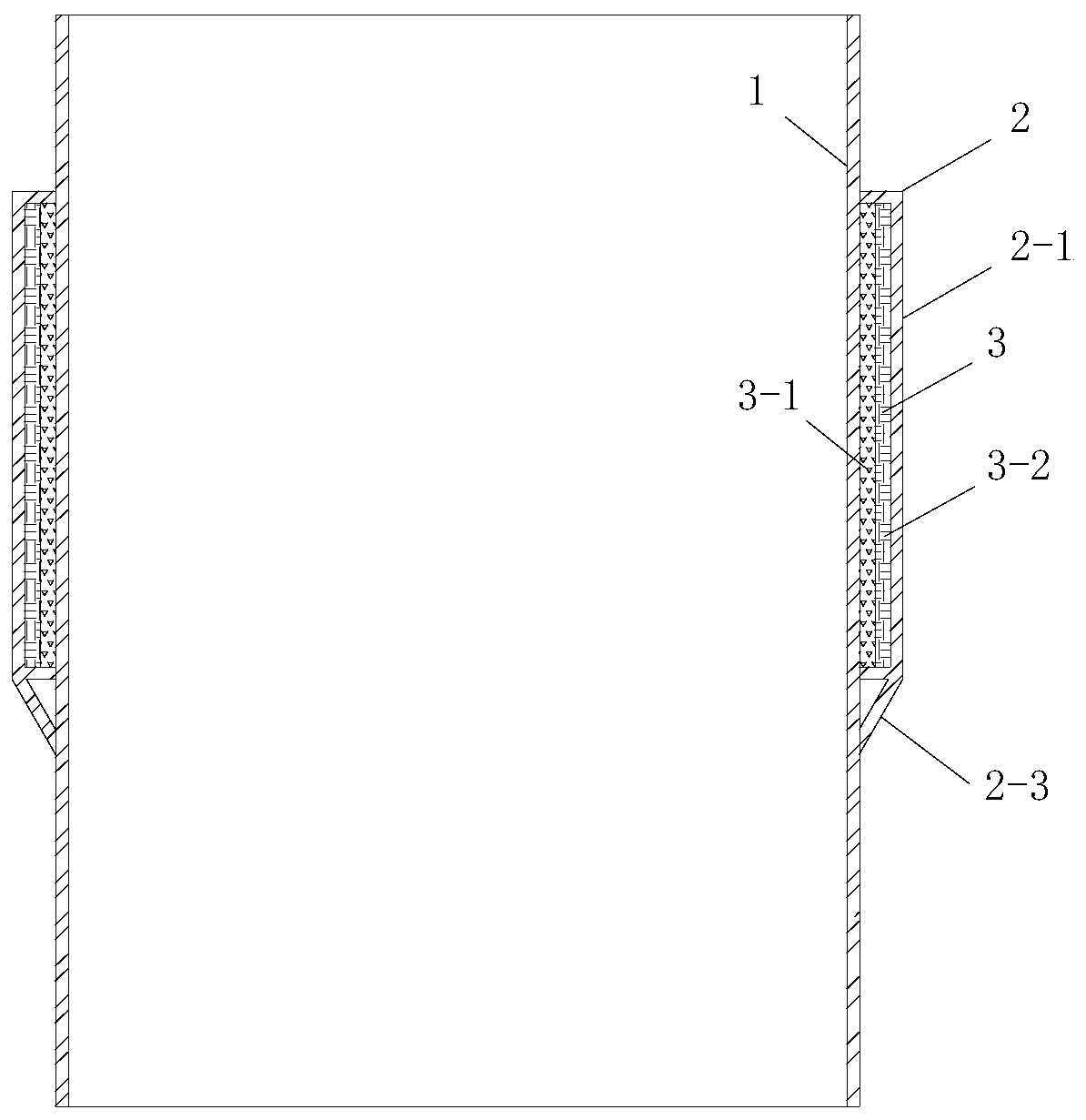

[0082] This embodiment provides a high-sensitivity soft soil area anti-skid bored pile foundation, which is used in river alluvial plains, river estuaries and underwater high-sensitivity soft soil slopes on the continental shelf. The pile foundation includes several new steel casings, several steel casing installation devices 6 and the main body of the bored pile; the main body of the bored pile includes several ordinary steel casings 8, steel cages 9 and concrete 10; all the new steel casings It is sealed and connected with all ordinary steel casings 8 from bottom to top; the new steel casing and the ordinary steel casing 8 are arranged with reinforcement cages 9 and poured with concrete 10;

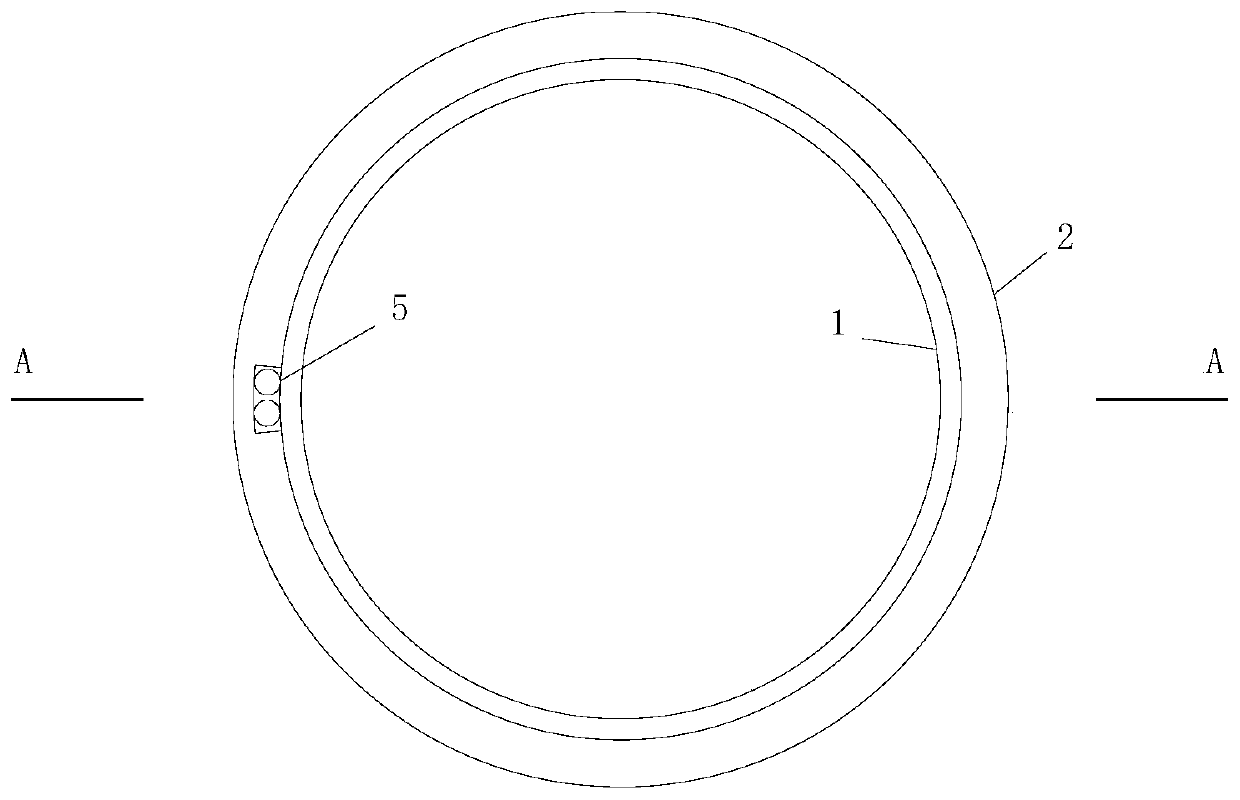

[0083] Such as Figure 1-4 As shown, the new steel casing includes an inner cylinder 1, an outer cylinder 2, a cavity 3 between the inner cylinder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com