A powerful mixing-granulation method for strengthening the sintering of high-proportion fine-grained raw materials

A fine-grained, high-proportion technology, applied in the field of iron and steel metallurgy, can solve the problems affecting the output of sintered ore, quality indicators, mixing, and difficulty in granulation, so as to improve the granulation effect, achieve efficient utilization, and reduce ineffective water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

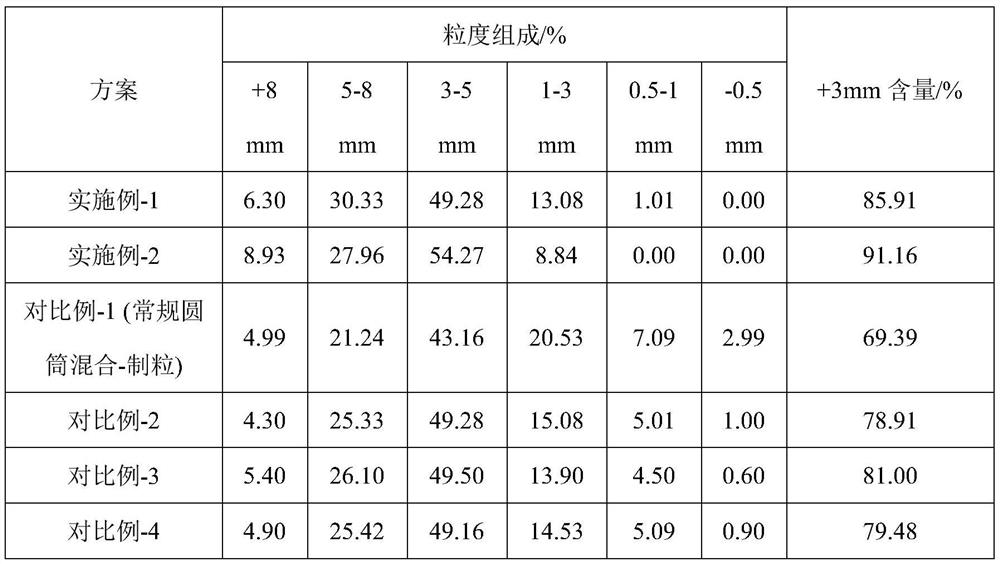

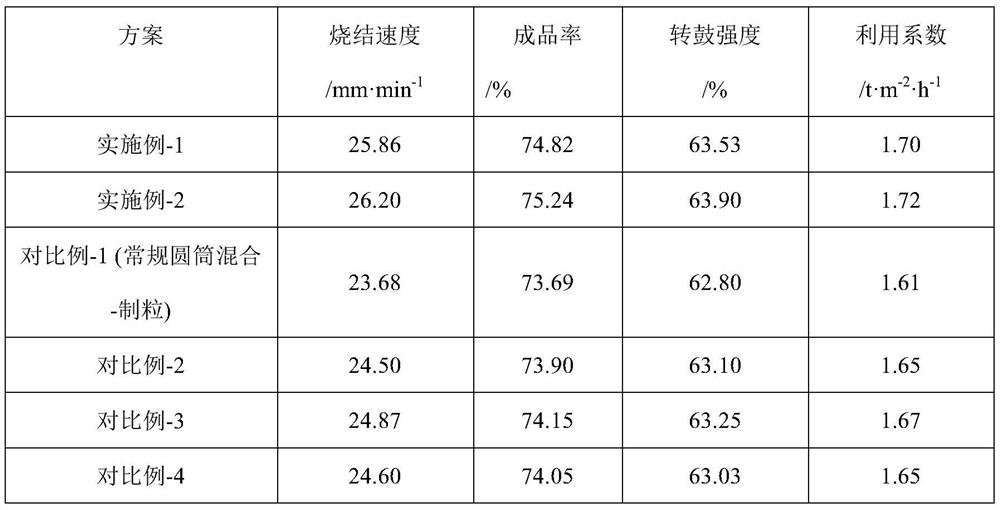

Embodiment 1

[0042] Weigh iron concentrate, iron ore powder, iron-containing dust, coke powder, quicklime, limestone, dolomite, fine-grained returned ore (particle size≤3mm), and coarse-grained returned ore (granularity>3mm), according to mass percentage, As shown in Table 1, the relative proportions of iron concentrate, iron ore powder, and iron-containing dust are shown in Table 2. Mix iron concentrate, iron ore powder, fuel, flux, and fine-grained return ore through the first cylinder, and spray water accounting for 50% of the total added water mass percentage, and the particle size of water droplets is controlled at 0.3-0.5mm ; Spray 1.5% sodium carboxymethyl cellulose solution in the iron-containing dust, the concentration is controlled at 0.2%, and the particle size of the atomized liquid beads is 0.1-0.15mm, and then it is mixed with the cylinder The mixed materials are sent to a strong mixer together, and water is sprayed to account for 20% of the total added water mass percentage,...

Embodiment 2

[0044] Iron concentrate, iron ore powder, iron-containing dust, coke powder, quicklime, limestone, dolomite, fine-grained and coarse-grained returned ore were weighed according to mass percentage, as shown in Table 1, where iron concentrate, iron The relative ratio of ore powder and iron-containing dust is shown in Table 2. Mix iron concentrate, iron ore powder, fuel, flux, and fine-grained return ore through the first cylinder, and spray water accounting for 50% of the total added water mass percentage, and the particle size of water droplets is controlled at 0.3-0.5mm ; Spraying 2.0% sodium carboxymethyl cellulose solution in the iron-containing dust, the concentration is controlled at 0.3%, and the particle size of the atomized liquid beads is 0.05-0.10mm, and then it is mixed with the cylinder The mixed materials are sent to a strong mixer together, and water is sprayed to account for 20% of the total added water mass percentage, and the water droplet size range is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com