A fluorescent ceramic and its preparation method, light source device and projection device

A fluorescent ceramic and fluorescent technology, applied in projection devices, chemical instruments and methods, optics, etc., can solve the problems of low blue light absorption rate, insufficient bonding strength, weak luminous performance, etc., and achieve high luminous intensity and improved structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

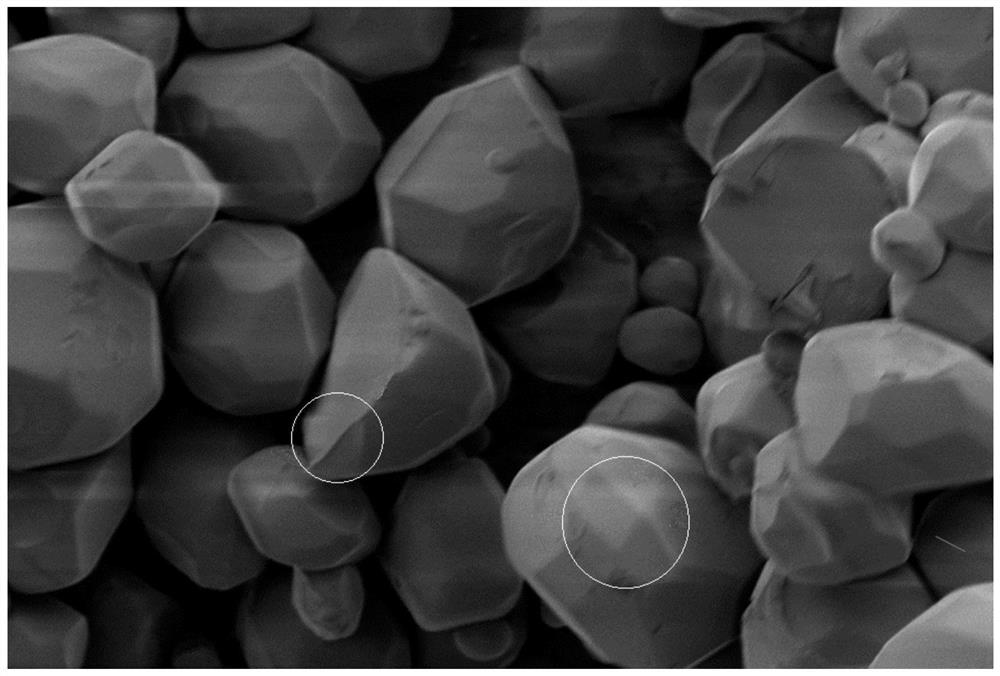

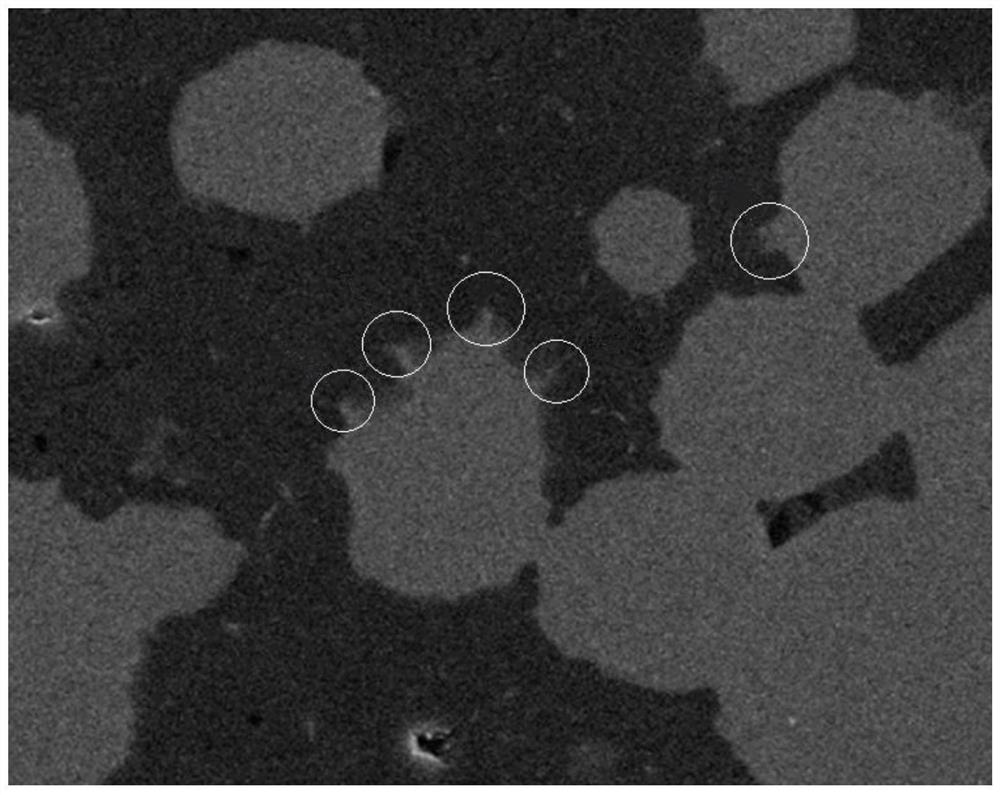

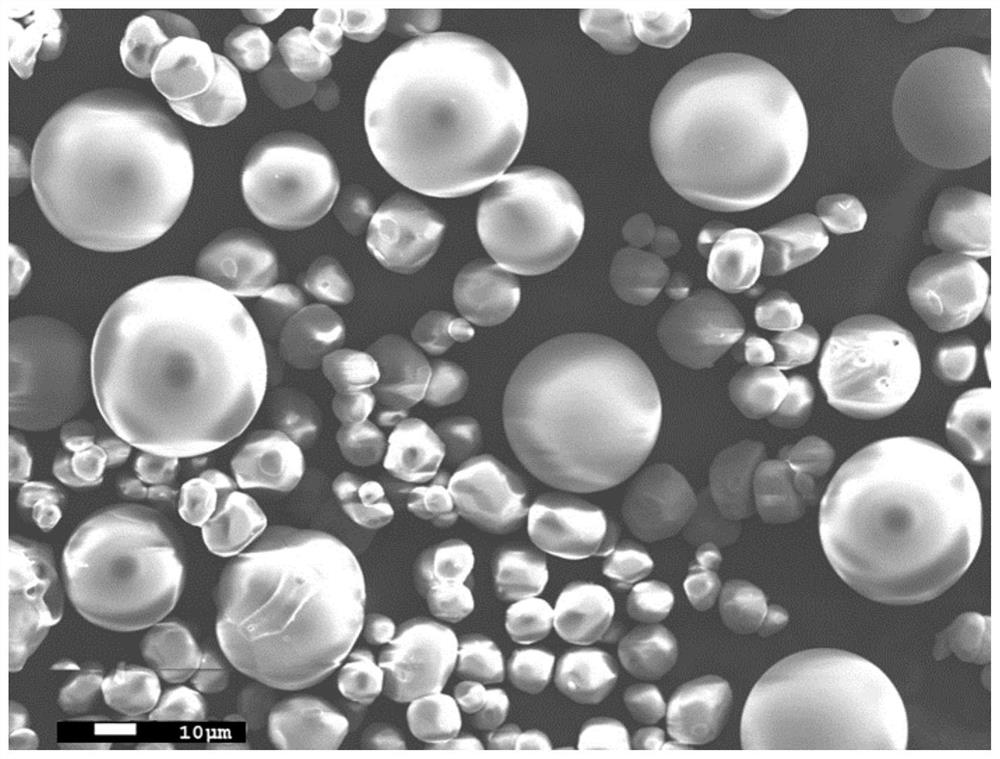

[0040] The preparation method and equipment of the spherical fluorescent single crystal particles of the present invention are described below, specifically as Figure 9 As shown, the present invention adopts the hydrogen flame melting method to prepare spherical fluorescent single crystal particles. The equipment used includes a barrel and a reaction barrel. The barrel is mainly used to accommodate raw material powder for phosphor powder. The barrel includes a powder outlet. Specifically , The particle size range of phosphor raw material powder is 2-20um. The above-mentioned reaction cylinder includes a powder feed port docked with the powder discharge port of the barrel, so that the phosphor raw material powder in the barrel enters through the powder feed port of the reaction barrel; the reaction barrel also includes an oxygen inlet and a hydrogen inlet. Oxygen and hydrogen in the reaction cylinder react in the combustion zone, providing temperature conditions for the liquef...

Embodiment 1

[0052] Prepare the YAG-Al of this embodiment according to the following steps 2 o 3 Fluorescent ceramics.

[0053] S1: Preparation of spherical fluorescent single crystal particles

[0054] It should be noted that the degree of powder liquefaction and the size of droplets can be controlled by controlling the temperature of the combustion zone and by controlling the injection quantity and injection speed of the raw material powder into the combustion zone, so as to control the particle size of the spherical fluorescent single crystal particles. size.

[0055] S2: Preparation of raw material powder for fluorescent ceramics

[0056] Raw materials: high-purity ultra-fine Al 2 o 3 Nano powder, the powder particle size is 0.05-1um, preferably 0.08-0.2um; select high-purity ultra-fine Y 2 o 3 Nano-powder with a particle size of 0.05-0.1um; high-purity ultra-fine MgO nano-powder with a particle size of 0.05-0.1um; YAG: Ce spherical fluorescent single crystal particles prepared ...

Embodiment 2

[0064] Prepare the YAG-Al of this embodiment according to the following steps 2 o 3 Fluorescent ceramics.

[0065] S1: Prepare YAG:Ce spherical fluorescent single crystal particles according to the method for preparing spherical fluorescent single crystal particles in step S1 in Example 1, preferably with a particle size of 30-50um.

[0066] S2: Preparation of raw material powder for fluorescent ceramics

[0067] Weigh Al 2 o 3 Powder, preferably high-purity Al with a particle size of 0.05-1um 2 o 3 Powder, in this embodiment, the commercial Al with a particle size of 0.1-0.2um can be selected as TM-DAR 2 o 3 The powder is selected from the YAG:Ce spherical fluorescent single crystal particles prepared in step S1, wherein Al 2 o 3 The volume ratio of powder to YAG:Ce spherical fluorescent single crystal particles is Al 2 o 3 :YAG=6:4. Will Al 2 o 3The powder and YAG:Ce spherical fluorescent single crystal particle powder are put into a polytetrafluoroethylene bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com