Active feeding hopper and feeding method

A feeding and hopper technology, which is applied to the hopper and feeding field of active feeding, can solve the problems of poor stirring uniformity, low success rate of nail suction, affecting the production rhythm of the nail taking mechanism, etc., and achieves convenient maintenance, high feeding efficiency, and reduced design. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

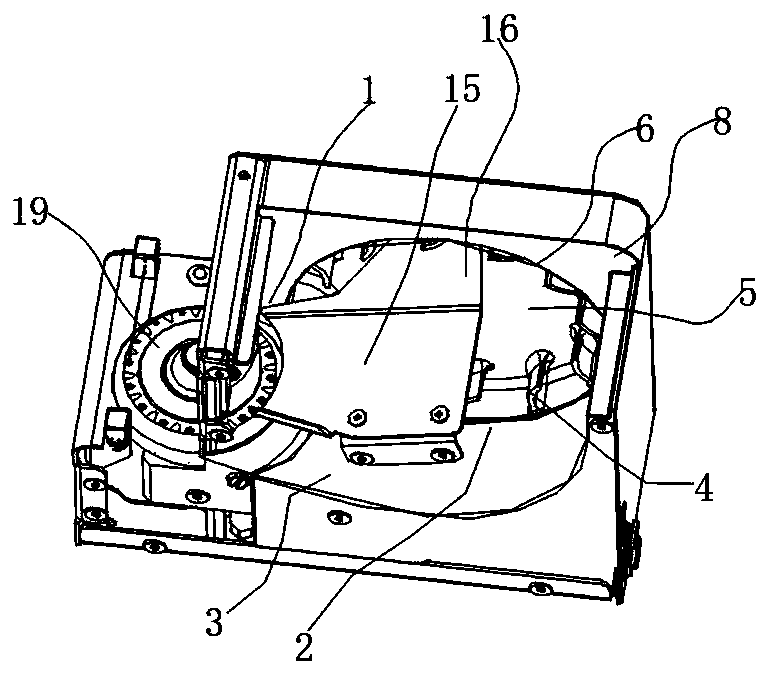

Embodiment 1

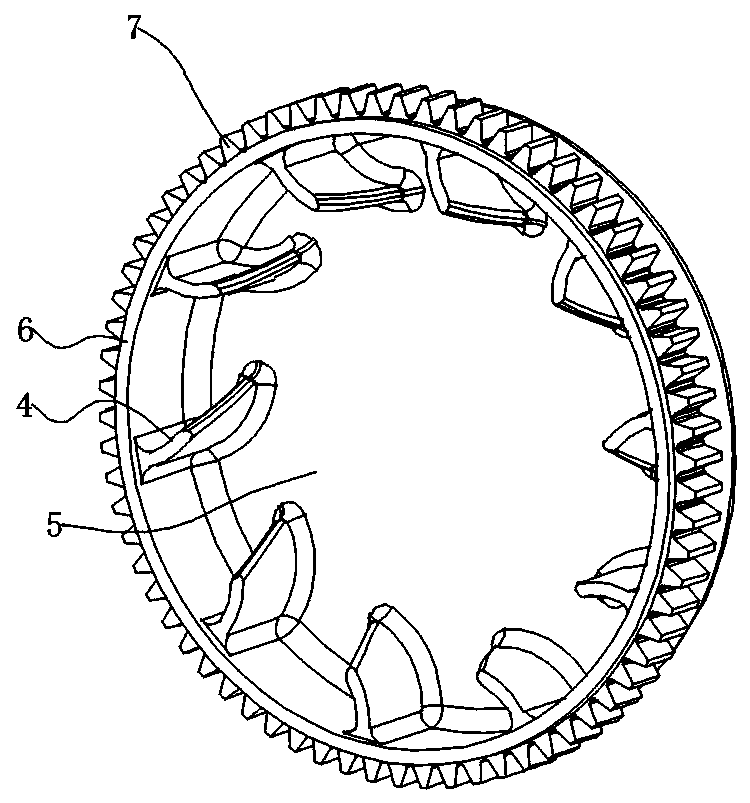

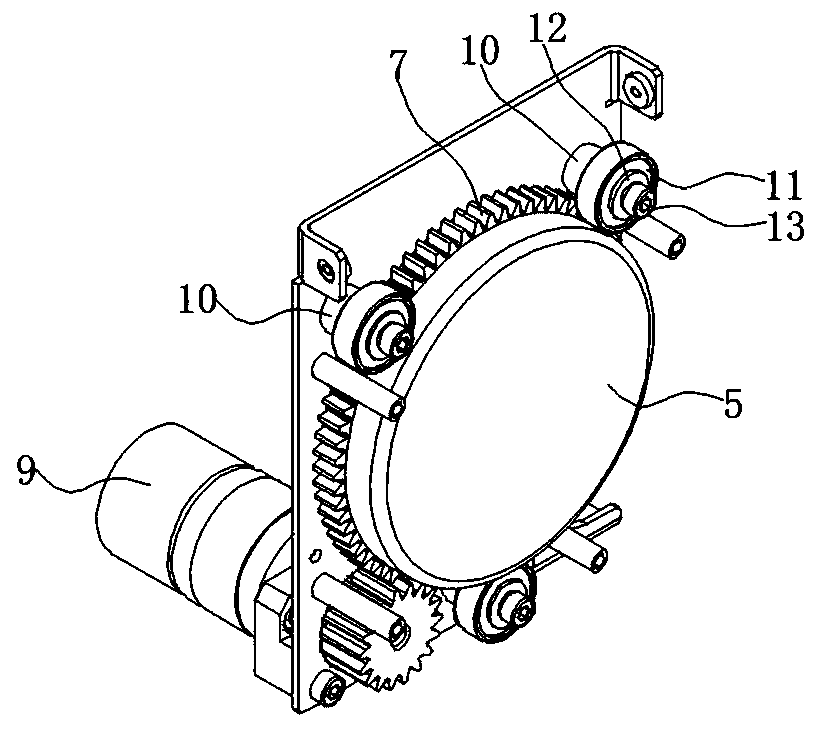

[0036]An active feeding hopper, which is characterized by including a silo, a collecting wheel and a first driving mechanism 9; the silo includes a blanking area 1, a collecting area 2 and an inclined plane 3, and the dropping area 1 is higher than the collecting area 2. The inclined plane 3 connects the blanking area 1 and the collecting area 2; the collecting wheel is connected to the silo at a vertical or inclined predetermined angle, and the collecting wheel is connected to the first driving mechanism 9; the circumferential wall of the collecting wheel 6 The lower edge of the lower edge is arranged in the collecting area 2, and is connected with the edge at the lowest point of the inclined plane 3; several blades 4 are arranged on the circumferential wall 6 of the collecting wheel.

[0037] The aggregate runner includes a bottom surface 5, a peripheral wall 6 connected to the bottom surface 5, a toothed disc 7 is arranged on the outside of the peripheral wall 6; a blade 4 i...

Embodiment 2

[0045] On the basis of embodiment 1, the collection area 2 and the blanking area 1 are set along the axial direction of the collection runner, and the inclined surface 3 is a cylindrical arc surface. At this time, the conveying mechanism 19 is in the axial direction of the collection runner. , the distance from the aggregate runner is relatively long. One end of the feeding slide 15 extends into the collecting wheel, and the other end is arranged above the blanking area 1 close to the conveying mechanism 19. The feeding sliding plate 15 is provided with a number of chutes 18 along the blanking direction. Drop to some chutes 18 on the feeding slide plate 17, drop on the conveying mechanism along the chute 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com