Coal briquette grinding device for boiler combustion

A boiler combustion and pulverizing technology, which is applied in the field of boilers, can solve the problems of small contact area, insufficient combustion, and time-consuming, and achieve the effect of intense combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

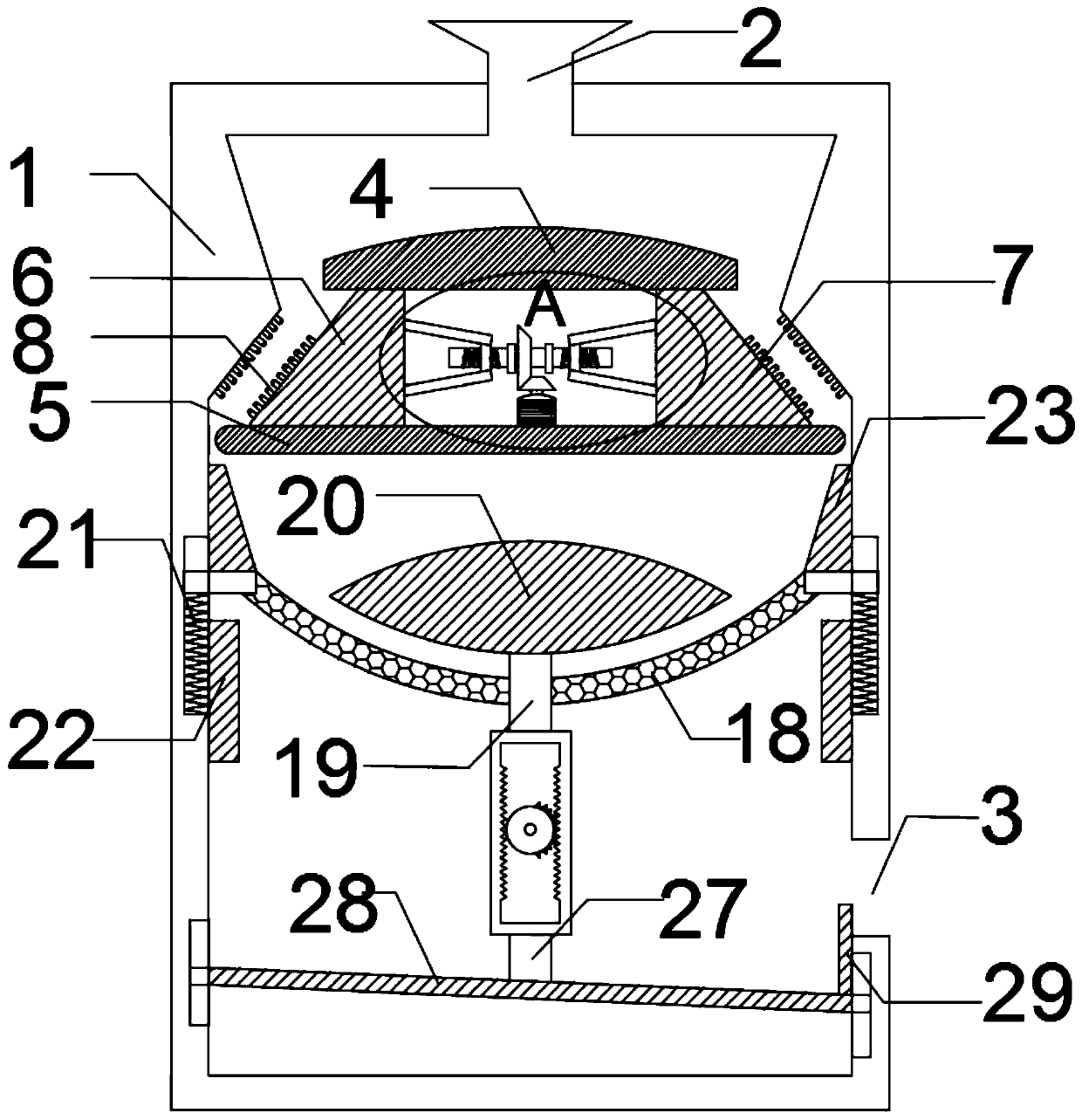

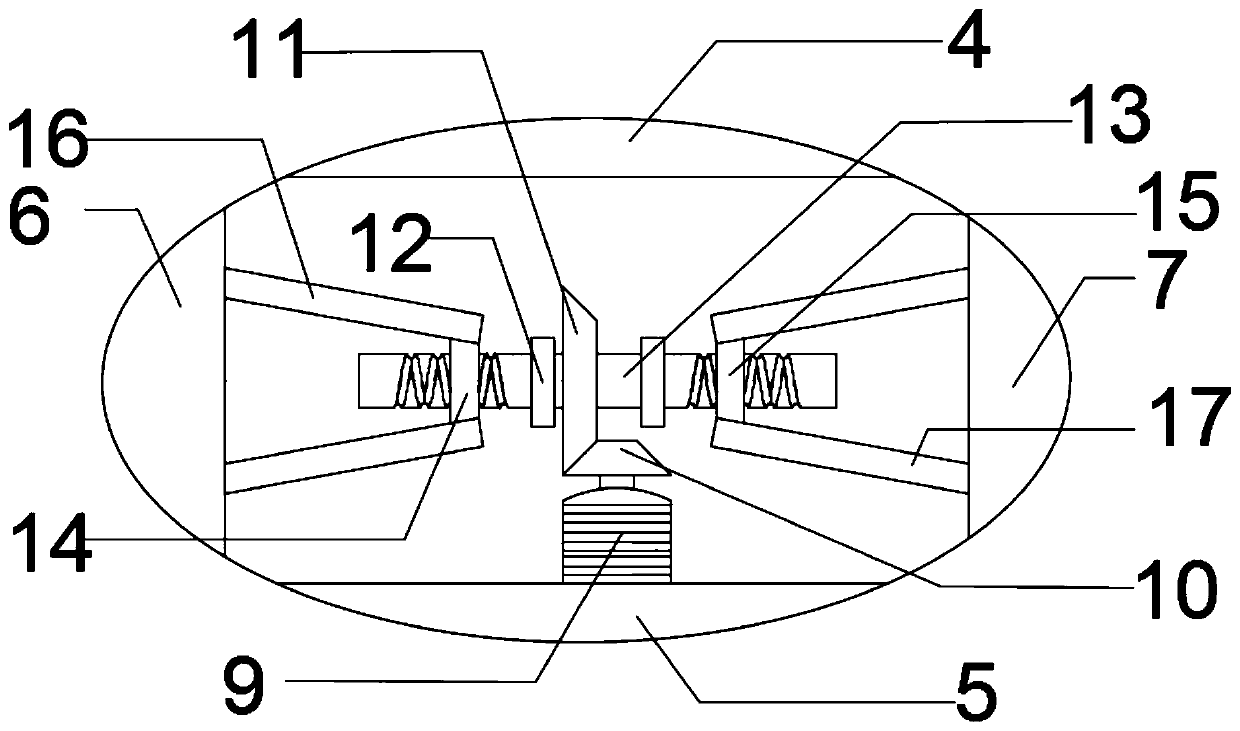

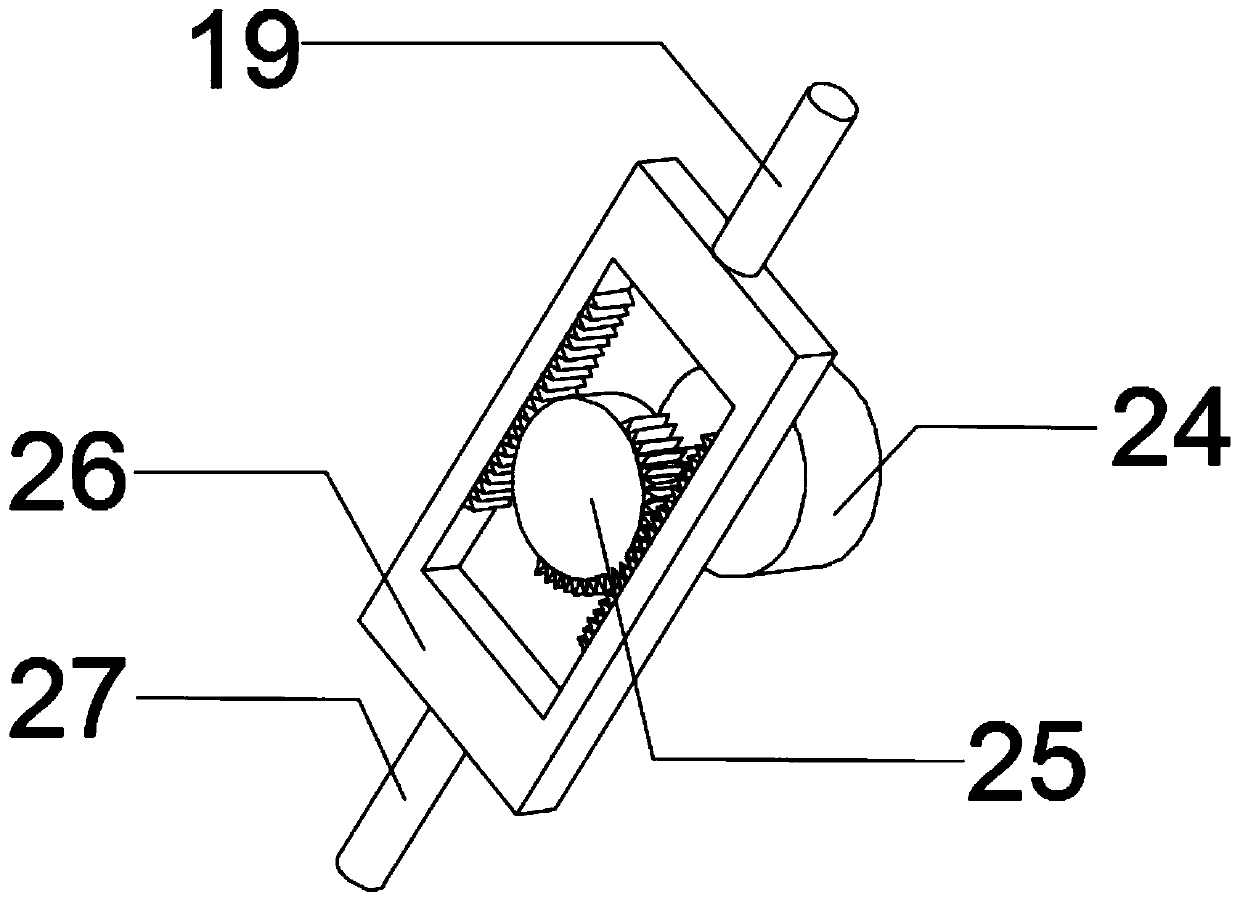

[0020] see Figure 1-4 , the present embodiment provides a coal pulverizing device for boiler combustion, comprising a device shell 1, a feed port 2, a discharge port 3 and a crushing mechanism; the upper and lower ends of the device shell 1 are respectively provided with feed ports 2 and the discharge port 3, and its inside is provided with a crushing mechanism; the crushing mechanism includes an upper fixed plate 4, a lower fixed plate 5, a left crushing sliding block 6, a right crushing sliding block 7 and a crushing drive mechanism; the The inside of the device shell 1 is fixed with an upper fixed plate 4 and a lower fixed plate 5 sequentially from top to bottom, and there is a gap between the left and right ends of the lower fixed plate 5 and the inner wall of the device shell 1, and the width of the gap is the diameter of the block coal; The left and right ends between the upper fixing plate 4 and the lower fixing plate 5 are fitted and slidably provided with a left grin...

Embodiment 2

[0028] This embodiment is further improved on the basis of Embodiment 1. The improvement is: in order to prevent coal lumps and coal powder from falling into the upper sliding groove and the lower sliding groove respectively, causing the grinding surface 18 and the discharge plate 28 to be unable to Movement; the two ends of the milling surface 18 are fixed with an upper sliding groove baffle 23, and the upper sliding groove baffle 23 fits with the inner wall of the device housing 1, and seals the upper sliding groove above the milling surface 18; The lower side of the discharge plate 28 is fixed with a lower sliding groove baffle 29 , and the lower sliding groove baffle 29 fits the inner wall of the device housing 1 and seals the lower sliding groove above the discharge plate 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com