Cobaltosic oxide in-situ coated silicon dioxide mesoporous sphere surface loaded noble metal catalyst, and preparation method and application thereof

A noble metal catalyst, cobalt tetroxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic activity and poor stability of methane, and achieve high activity High, low cost, excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

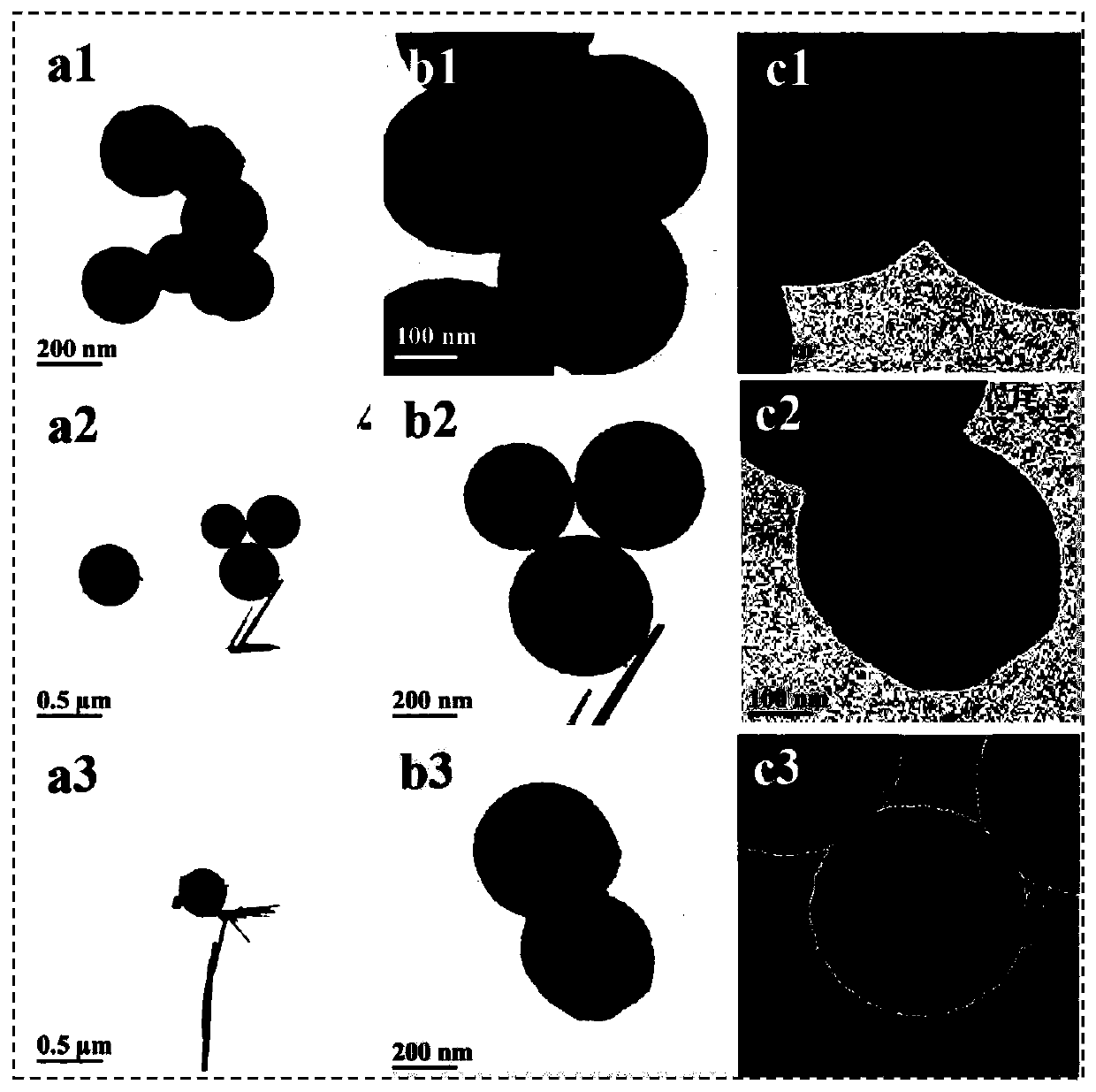

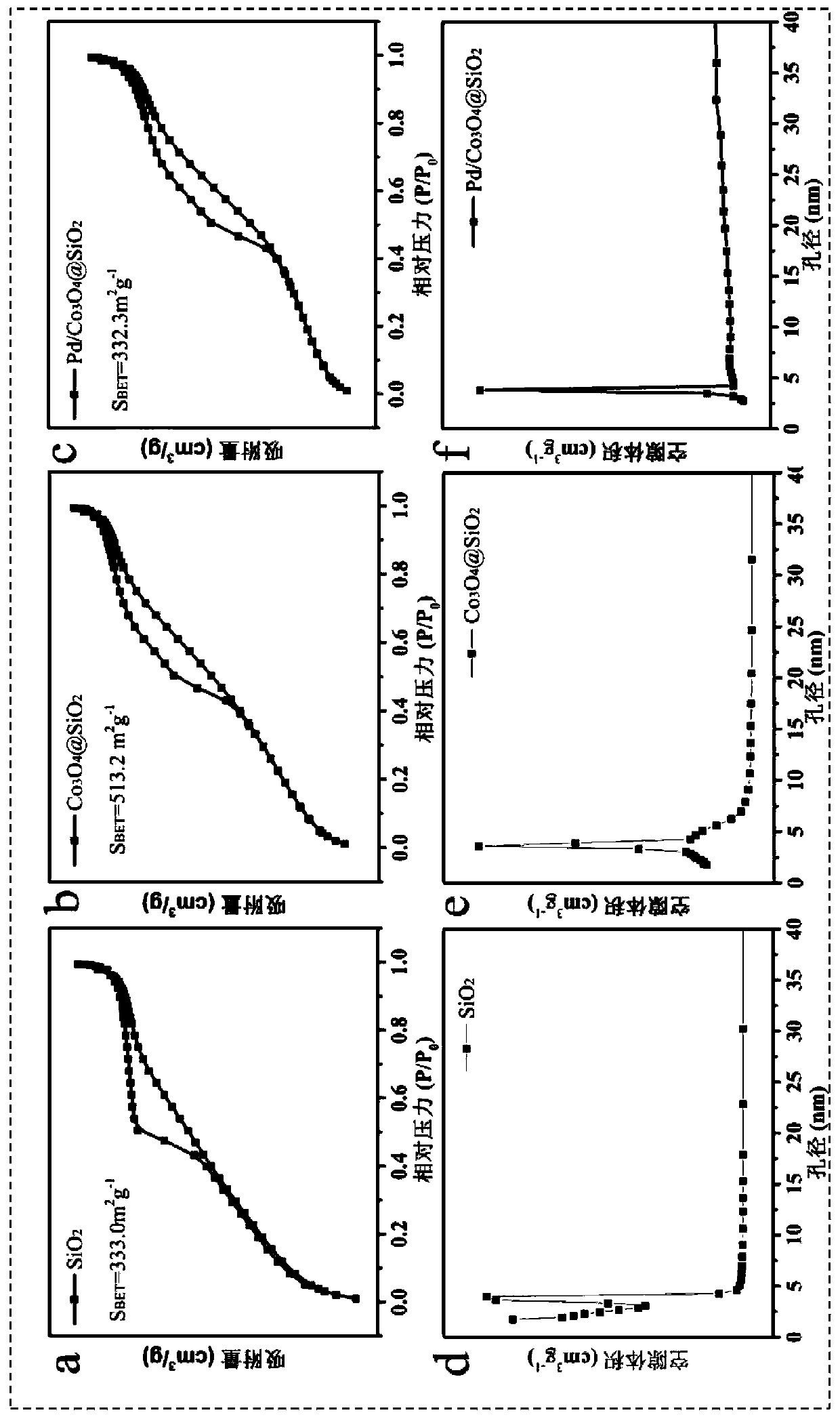

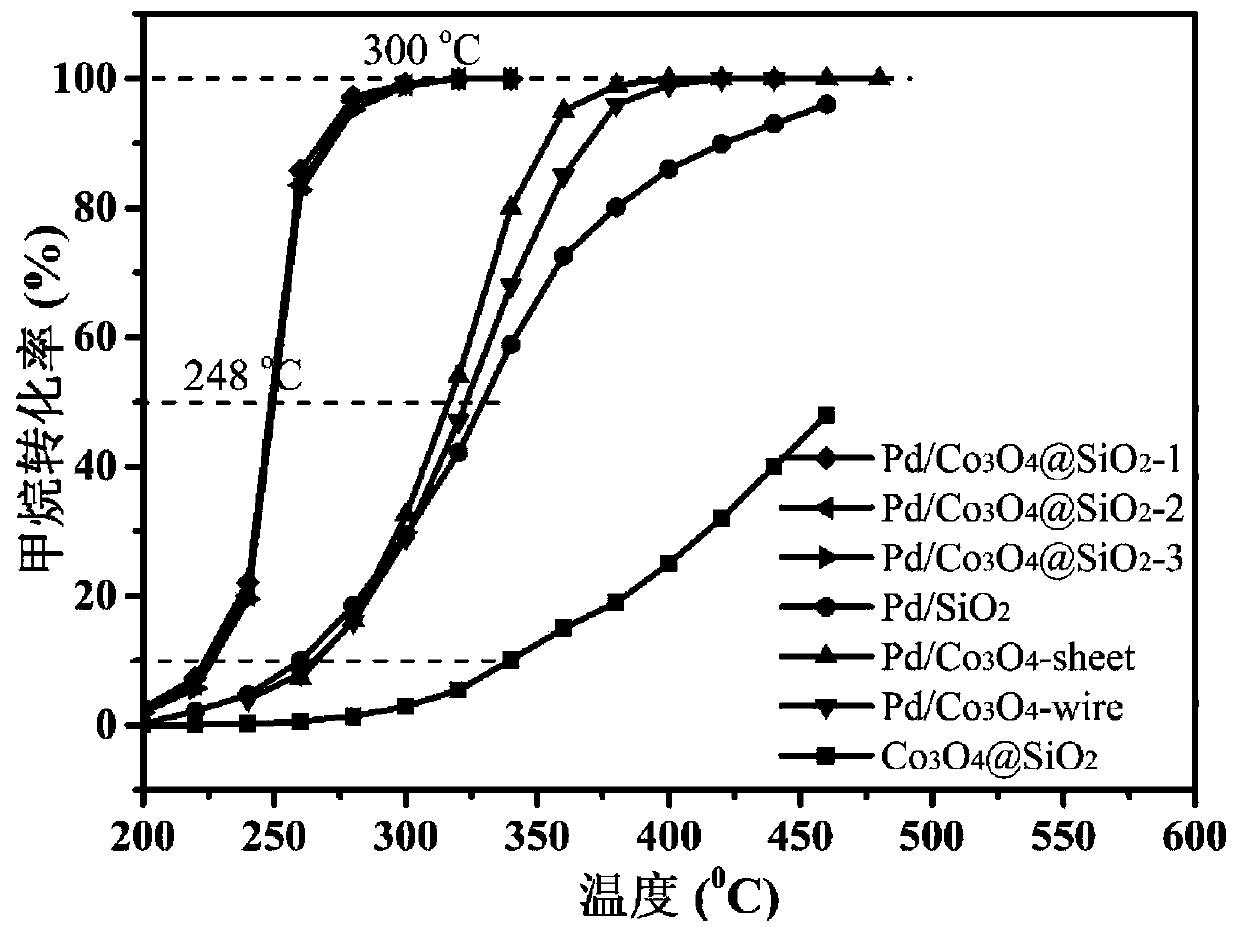

[0061] A preparation method of in-situ coated silica mesoporous spheres with cobalt tetroxide supporting precious metal catalysts includes the following steps:

[0062] (1) Mix 24mL of absolute ethanol, 1.0mL of ammonia (25wt%) and 80mL of water evenly, stir at 200rpm for 10min, add 0.4g of dopamine hydrochloride and 1mL of tetraethyl silicate, the clear solution gradually becomes turbid After 5 minutes, the solution gradually became black and turbid, then stirred for 6 hours at a rate of 600 rpm; filtered the precipitate, washed the precipitate with deionized water 3 times, centrifuged (8000r / min), and then dried at 80°C Dry in a box for 2 hours, and finally put the product in a tube furnace, bubbling with nitrogen, and calcining at 800℃ for 4 hours to prepare SiO containing carbon nitride 2 Microsphere, named NC-SiO 2 ;

[0063] (2) Weigh 1.0g of SiO containing carbon nitride described in step (1) 2 The microspheres were dissolved in 100 mL of water and stirred uniformly to obtai...

Embodiment 2

[0069] A preparation method of in-situ coated silica mesoporous spheres with cobalt tetroxide and a noble metal catalyst supported on the surface thereof includes the following steps:

[0070] (1) Mix 24mL of absolute ethanol, 1.0mL of ammonia (25wt%) and 80mL of water evenly. After stirring for 10min at 200rpm, add 0.4g of dopamine hydrochloride and 2mL of tetraethyl silicate, the clear solution gradually becomes turbid. After 5 minutes, the solution gradually became black and turbid, and then stirred for 6 hours at a rate of 600 rpm; the precipitate was filtered, washed with deionized water for 3 times, then centrifuged (8000r / min), and then placed in a drying cabinet at 80°C Dry for 2h in the medium, and finally put the product in a tube furnace, bubbling with nitrogen, and calcining at 800℃ for 5h to prepare SiO containing carbon nitride. 2 Microspheres, named NC-SiO 2 ;

[0071] (2) Weigh 1.0 g of SiO containing carbon nitride described in step (1) 2 The microspheres were diss...

Embodiment 3

[0076] A preparation method of in-situ coated silica mesoporous spheres with cobalt tetroxide supporting precious metal catalysts includes the following steps:

[0077] (1) Mix 24mL of absolute ethanol, 1.0mL of ammonia (25wt%) and 80mL of water evenly. After stirring for 10 minutes at 200rpm, add 0.4g of dopamine hydrochloride and 3mL of tetraethyl silicate, the clear solution gradually becomes turbid. After 5 minutes, the solution gradually became black and turbid, and then stirred for 6 hours at a rate of 600 rpm; the precipitate was filtered, washed with deionized water for 3 times, and then centrifuged (8000r / min), and then placed in a drying cabinet at 80°C Dry for 2h in the medium, and finally put the product in a tube furnace, bubbling with nitrogen, and calcining at 800℃ for 6h to prepare SiO containing carbon nitride. 2 Microsphere, named NC-SiO 2 ;

[0078] (2) Weigh 1.0 g of SiO containing carbon nitride described in step (1) 2 The microspheres were dissolved in 100 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com