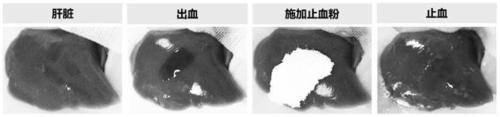

Preparation method of hemostatic agent with rapid diffusion mixing function

A diffusion mixing and hemostatic agent technology, applied in surgical adhesives, pharmaceutical formulations, applications, etc., can solve the problems of not having rapid diffusion and rapid coagulation, easy to be washed away by blood, and unsatisfactory hemostasis effect, etc., to achieve good bioavailability Effects of degradability, coagulation phase and kinetic phase stabilization, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

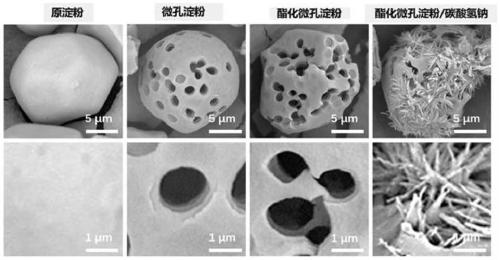

[0043] A rapid diffusion mixed function hemostatic agent, its preparation method comprises the following steps:

[0044] S1: Add 40g of cornstarch to 200ml of sodium acetate buffer solution with a pH of 4.6 containing α-amylase and glucoamylase for reaction, heat at 40°C and stir at a speed of 250r / m for 10h, filter after the reaction is completed, wash the filter residue, and vacuum Dry for 24 hours to obtain microporous starch; then add 20 g of the obtained microporous starch to deionized water containing 0.6 g of sodium carbonate and 1.2 g of sodium trimetaphosphate, heat at 50°C for 24 hours, and add sodium hydroxide solution during the reaction to maintain the solution The pH value is 11, after the reaction is completed, add hydrochloric acid, filter, wash and dry to obtain esterified microporous starch; wherein, the ratio of α-amylase to glucoamylase is 1:4, and the ratio of amylase to cornstarch is 2: 100.

[0045] S2: Stir 10 g of the esterified microporous starch obt...

Embodiment 2

[0049] A rapid diffusion mixed function hemostatic agent, its preparation method comprises the following steps:

[0050] S1: Add 40g of tapioca starch to 200ml of sodium acetate buffer solution containing α-amylase and glucoamylase at a pH of 4.6 to react, heat at 35°C and stir at a speed of 250r / m for 12h, filter after the reaction is completed, wash the filter residue, and vacuum Dry for 24 hours to obtain microporous starch; then add 20 g of the obtained microporous starch to deionized water containing 0.2 g of sodium carbonate and 0.8 g of sodium hexametaphosphate, heat at 50°C for 24 hours, and add sodium hydroxide solution during the reaction to maintain the solution The pH value is 11, after the reaction is completed, add hydrochloric acid, filter, wash and dry to obtain esterified microporous starch; wherein, the ratio of α-amylase and glucoamylase is 1:4, and the ratio of amylase and tapioca starch is 2: 100.

[0051] S2: Stir and mix 10 g of the esterified microporo...

Embodiment 3

[0055] A rapid diffusion mixed function hemostatic agent, its preparation method comprises the following steps:

[0056] S1: Add 40g of wheat starch to 200ml of sodium acetate buffer solution with a pH of 4.6 containing α-amylase and glucoamylase for reaction, heat at 55°C and stir at a speed of 250r / m for 6h, filter after the reaction is completed, clean the filter residue, and vacuum Dry for 24 hours to obtain microporous starch; then add 20 g of the obtained microporous starch to deionized water containing 2 g of sodium carbonate and 4 g of sodium tripolyphosphate, heat at 50°C for 24 hours, and add sodium hydroxide solution during the reaction to maintain the pH value of the solution After the reaction is completed, add hydrochloric acid, filter, wash and dry to obtain esterified microporous starch; wherein, the ratio of α-amylase to glucoamylase is 1:4, and the ratio of amylase to wheat starch is 2:100.

[0057] S2: Stir and mix 10g of the esterified microporous starch ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com