Hydrostatic plain bearing arrangement

A hydrostatic sliding bearing and sliding bearing technology, which is applied to bearing components, bearings, linear motion bearings, etc., can solve problems such as energy efficiency problems of hydrostatic sliding bearing assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

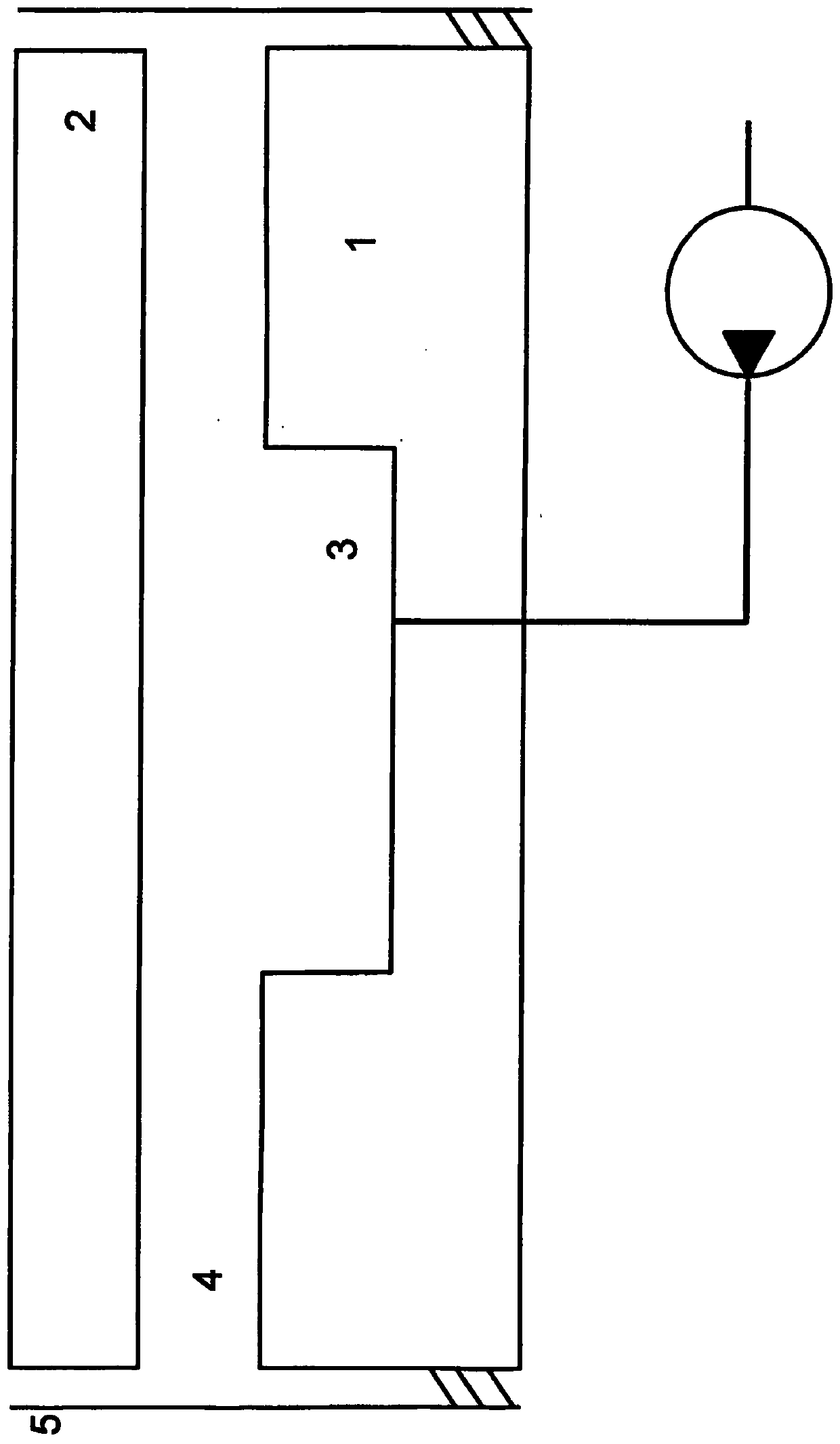

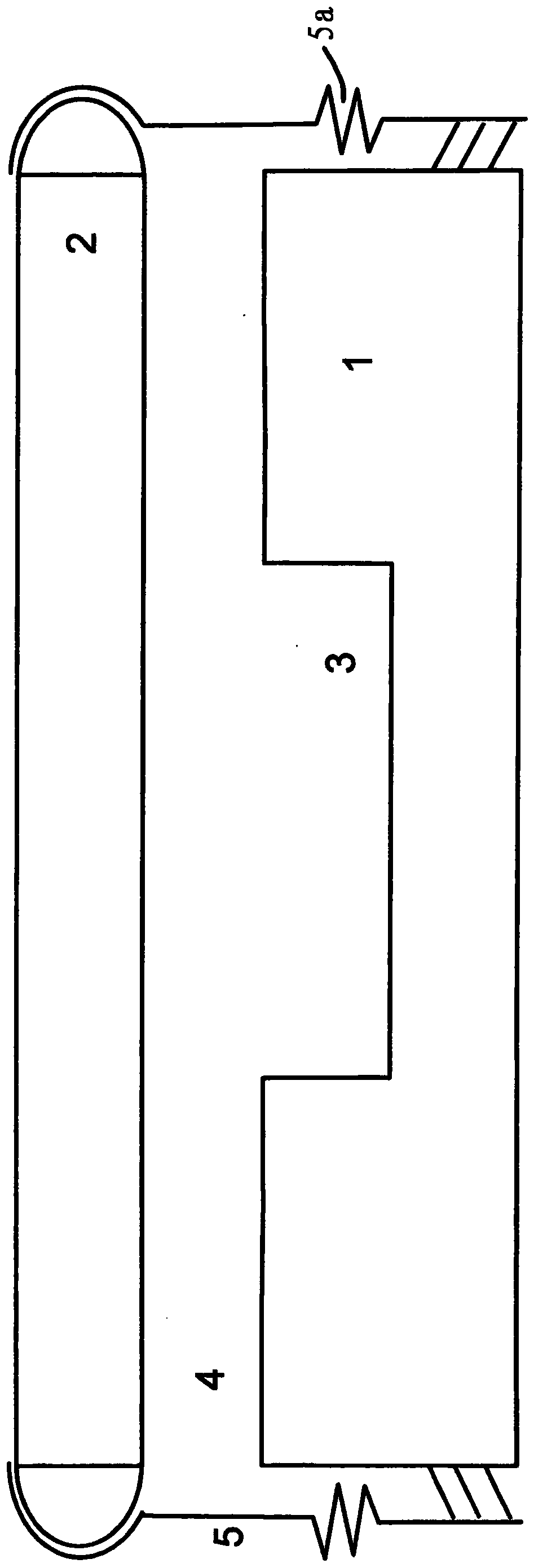

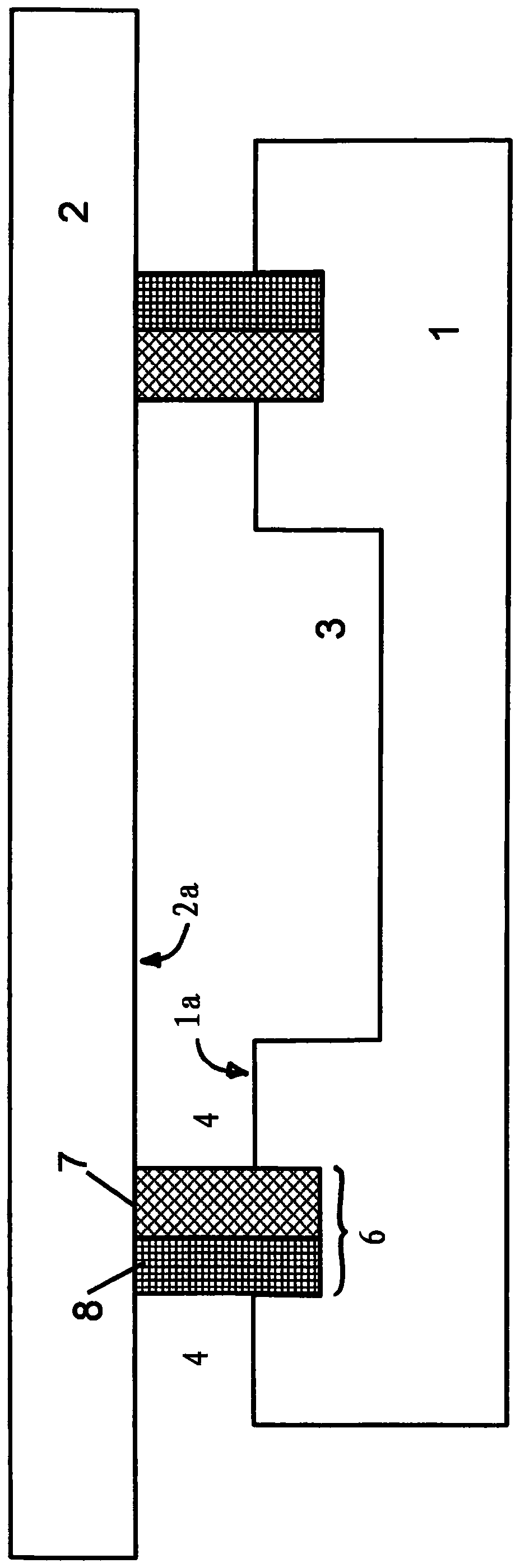

[0064] figure 1 An embodiment is shown in which the plain bearing assembly is formed by a lower bearing element 1 and an upper bearing element 2 . Arranged in the lower bearing element is a recess 3 which forms a bearing chamber which is open in the direction of the opposite bearing element 2 . Such a bearing chamber 3 is filled with a preferably liquid fluid which is acted upon with hydrostatic pressure via an external pressure supply (shown here as a pump). For this purpose, a corresponding fluid delivery into the recess 3 takes place by the pressure supply. This embodiment of the pressure supply device is also suitable for the other embodiments shown below, although they are not shown here.

[0065] Between the two bearing elements 1 , 2 there is a bearing gap 4 which is substantially filled with the fluid of the bearing chamber 3 .

[0066] The two bearing elements 1 , 2 are separated from one another by the hydrostatic pressure action, so that there is no solid-body co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com