Copper-indium-gallium-selenium thin-film solar cell absorption layer surface treatment device

A technology for surface treatment devices and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable industrial production, achieve the effects of improving surface performance, reducing the number, and increasing the number of photogenerated carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

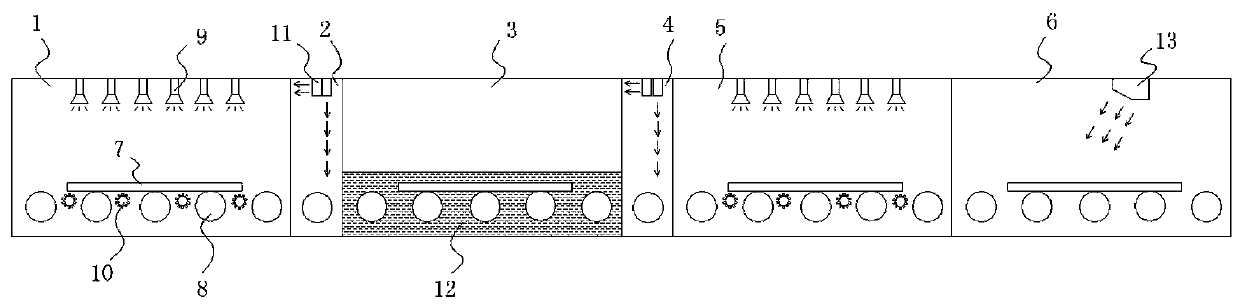

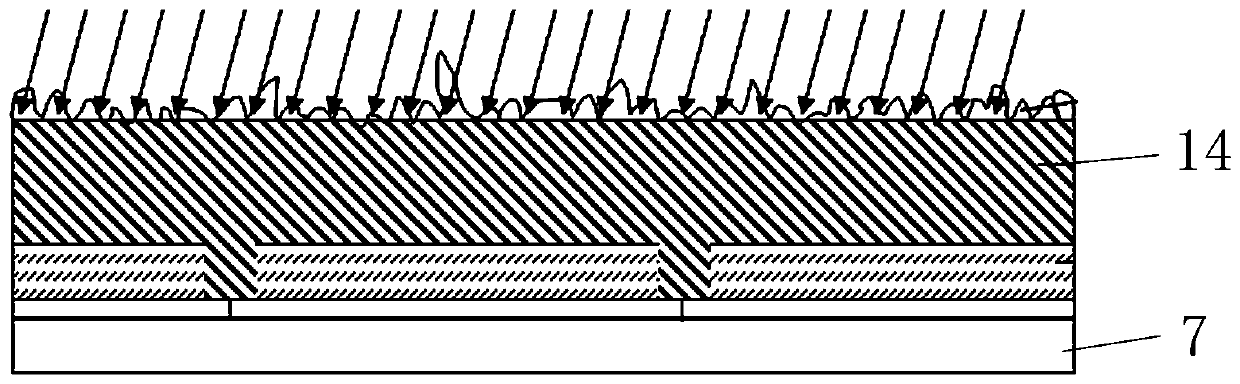

[0015] Such as figure 1 As shown, the present invention provides a surface treatment device for the absorbing layer of a copper indium gallium selenide thin film solar cell, comprising a first cleaning chamber 1, a first air knife drying chamber 2, a chemical reaction chamber 3, and a second wind Knife drying chamber 4, second cleaning chamber 5 and heating drying chamber 6, each chamber is provided with conveying roller table 8 for transporting substrate 7; above the conveying roller table in first cleaning chamber 1 Plasma water spraying equipment 9, roller brush cleaning equipment 10 are arranged at intervals between the conveyor rollers; the upper part in the first air knife drying chamber 2 is provided with air knife drying machine 11, as preferably, air knife drying The machine comprises two, one blows vertically downward, and the other blows horizontally toward the first cleaning chamber 1; chemical dissolving agent 12 is stored in the chemical reaction chamber 3, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com