Road pipeline burying assembly, pipeline burying method, and production device and method of pipeline burying assembly

A technology of pipe components and roads, which is applied in the direction of roads, roads, pipeline laying and maintenance, etc., can solve the problems affecting the integrity of the service life of the road surface, can not achieve effective management, and the iron plate is not conducive to the driving of vehicles, etc., to ensure the use of Longevity, rapid installation, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

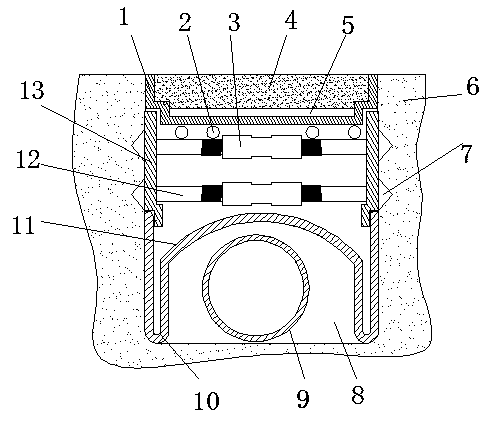

[0035] As shown in the drawings, a road buried pipe assembly of the present invention includes a filling structure, a support groove structure and a protective cover 11; a buried pipe groove 8 is opened on the road and the pipe body 9 is placed in the buried pipe groove 8 to protect The cover 11 is used to cover the top of the pipe body 9, the support groove structure is located above the protective cover 11 and is used to press against the side wall of the tank body, the filling structure is arranged above the support groove structure and its upper surface is flush with the ground;

[0036] The filling structure includes a supporting mold 1 and a filling layer 4. An upwardly opening filling groove is arranged on the inner side of the supporting mold 1, and a grid supporting layer 5 integrally formed with the supporting mold 1 is arranged at the bottom of the filling groove. The grid supporting layer 5 is in the shape of a cross grid, and a filling layer 4 is arranged in the fi...

Embodiment 2

[0044] The buried pipe method of the buried pipe assembly in embodiment 1 may further comprise the steps:

[0045] Step 1: Plan the slotting path on the road surface, divide the slotting path into sections with a length of 5-8m, and set up buried pipe grooves 8 on the road surface in sequence according to the segmentation sequence on the road surface; the depth of buried pipe groove 8 is the pre-buried Twice the diameter of the pipeline body 9, and the depth is 1.5-3 times the diameter of the embedded pipeline body 9;

[0046] Step 2: Put the pipe body 9 into the buried pipe groove 8, cover the protective cover 11 above the pipe body 9, then adjust the rotating sleeve 3 to shorten the distance between the two pressing plates 13, and place the The support groove structure is put into the buried pipe groove 8;

[0047] Step 3: draw lines on the side walls of both sides of the buried pipe groove 8, and the distance between the drawn line position and the ground is 4-6cm; draw th...

Embodiment 3

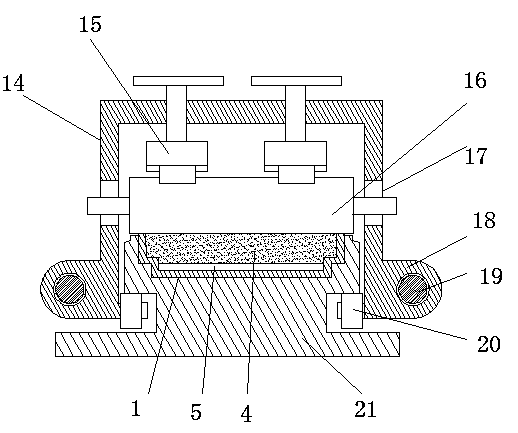

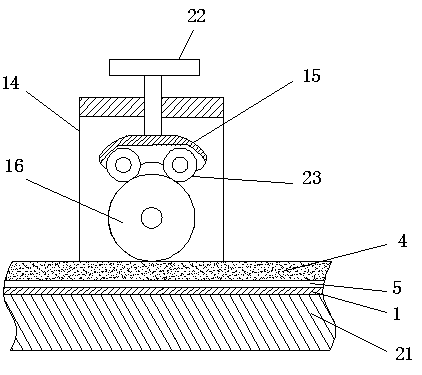

[0050] The production device of the filling structure in embodiment 1: comprises pallet 21, gantry 14, pressurization mechanism, extrusion roller 16 and transmission mechanism, and pallet 21 top is provided with the mold groove that cooperates supporting mold 1 to place, and supports The upper part of the mold 1 is flush with the notch of the mold groove; the two sides of the pallet 21 are provided with chute respectively, the portal frame 14 is covered on the pallet 21, and the inner side of the lower part of the portal frame 14 is respectively connected with a pulley 20 , the gantry 14 presses against the chute by pressing the pulley 20 and moves along the chute; the arms on the left and right sides of the gantry 14 are provided with vertical waist-shaped holes 17, and the extrusion rollers 16 are horizontally arranged on the The inner side of the portal frame 14 and its two ends penetrate in the waist-shaped hole 17 to limit its extrusion roller 16; Outside the lower part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com