A solenoid valve coil assembly

A technology of solenoid valve coils and components, applied in the direction of electromagnets, electrical components, electromagnets with armatures, etc., can solve the problem that the coil and current limiting components cannot be used, the water inlet solenoid valve cannot be used, and the aluminum wire uses too much copper wire. and other problems, to achieve the effect of compact product structure, reduce coil temperature rise, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments.

[0031] In this application, all the contents are directly described in the specification of the parent application, or can be inferred without doubt from the specification of the parent application.

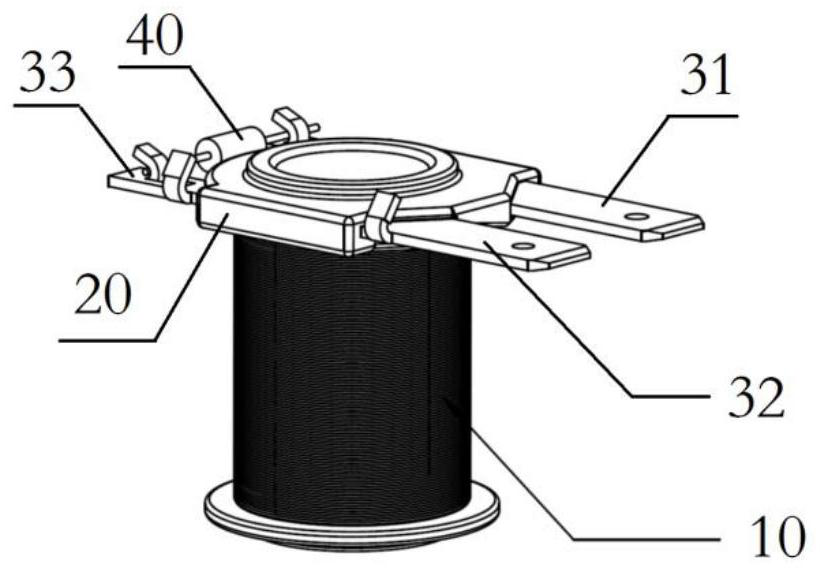

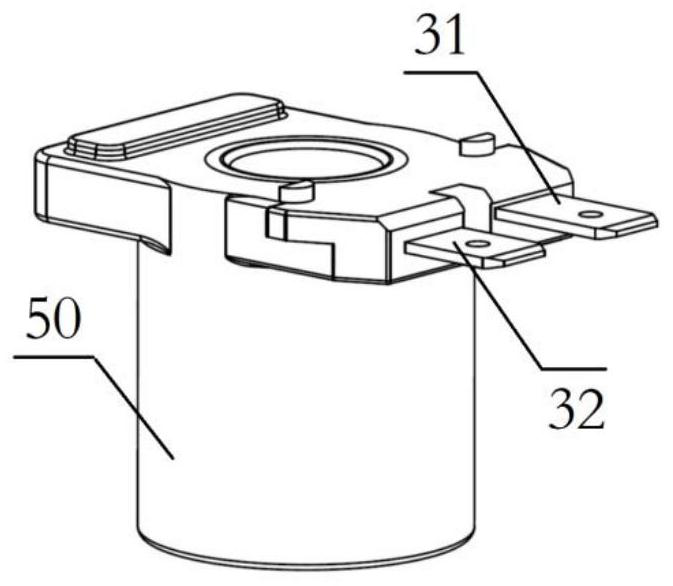

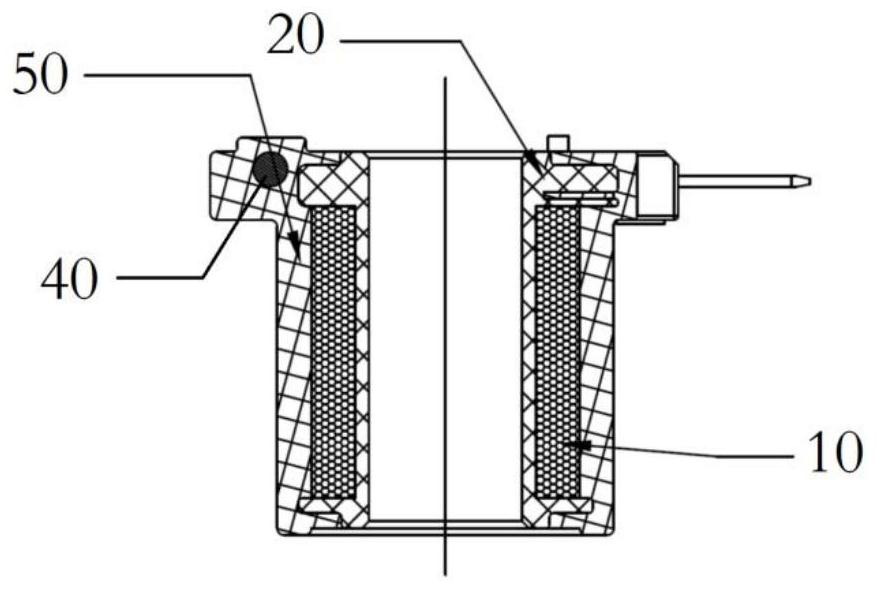

[0032] As the first embodiment of the present invention (embodiment 1 from the specification of the parent application), such as Figure 1-3 As shown, the coil assembly includes a coil 10 , a coil frame 20 , a first insert 31 , a second insert 32 , a third insert 33 and a current limiting element 40 . Such as Figure 4 As shown, the bobbin 20 is a cylindrical plastic part with an end face 21 at one end. The coil 10 is wound on the bobbin cylinder, and the two ends of the coil 10 respectively form the lead-out end and the lead-out end. Such as Figures 1 to 5 As shown, a first insertion piece 31 , a second insertion piece 32 and a third insertion piece 33 are plugged into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com