A coal mine underground drilling rig hydraulic oil online monitoring and automatic control system

A technology of hydraulic oil and coal mines, which is applied in the field of online monitoring and automatic control system of hydraulic oil in coal mines, and can solve the problems of hydraulic parts wear, unfiltered hydraulic system, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

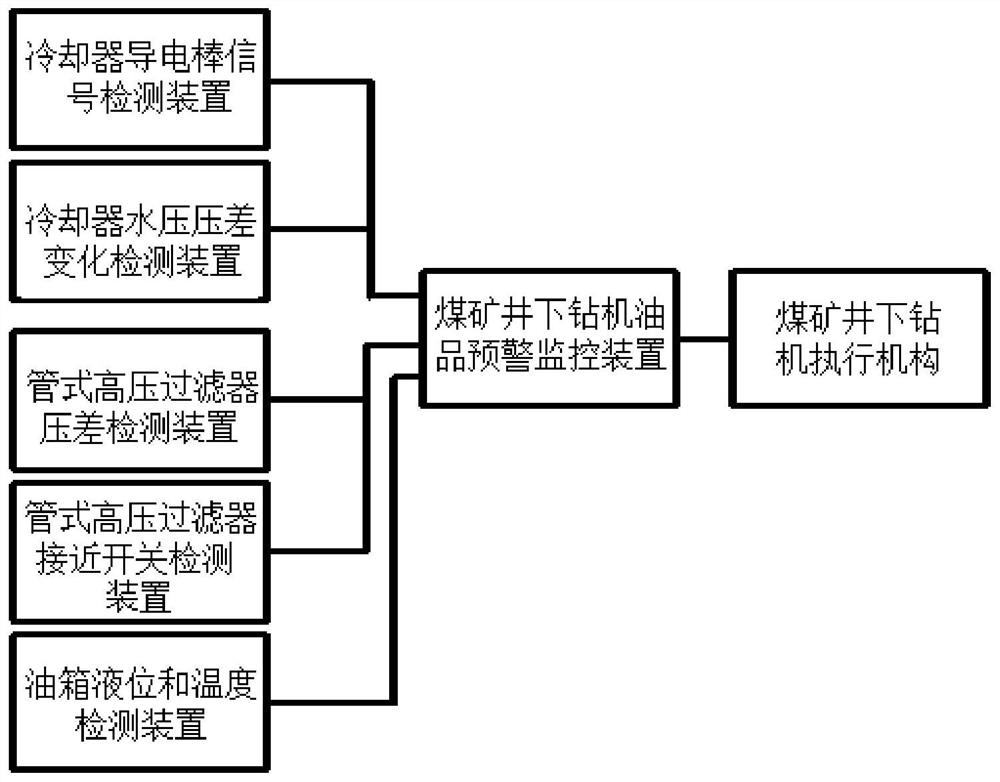

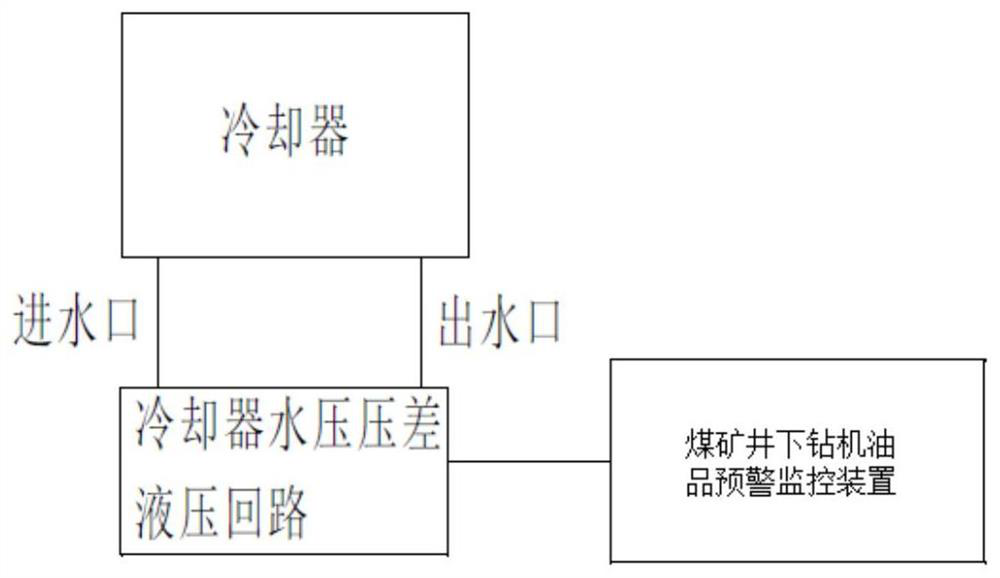

[0046] like Figure 1 to Figure 6 As shown, this embodiment provides an online monitoring and automatic control system for the hydraulic oil of an underground drilling rig in a coal mine, which includes an oil product early warning and monitoring device for an underground drilling rig in a coal mine, a signal detection device for a conductive rod of a cooler, a detection device for a change in water pressure of a cooler, and a pipe Type high-pressure filter differential pressure detection device, tubular high-pressure filter proximity switch detection device and oil tank liquid level and temperature detection device;

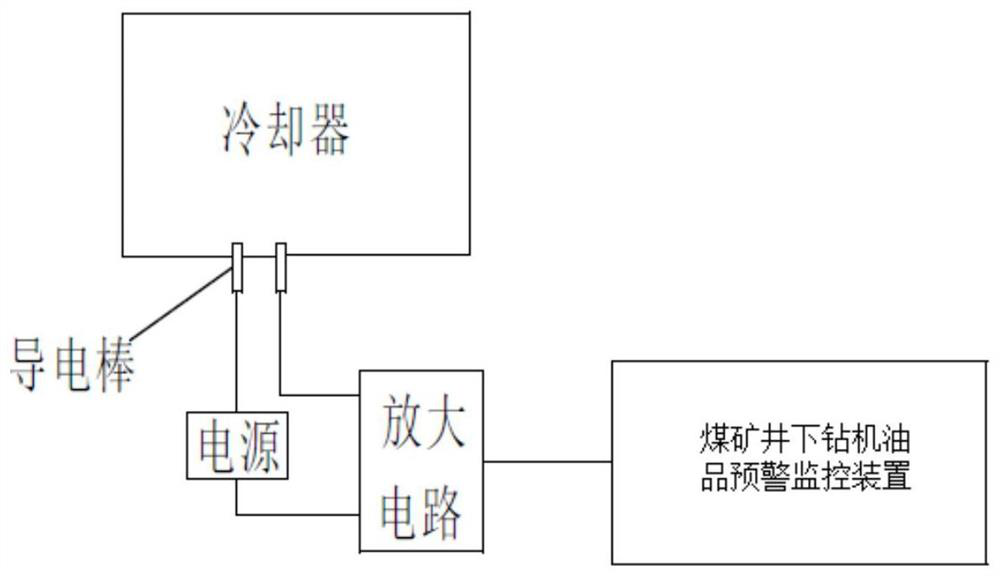

[0047] The cooler conductive rod signal detection device is connected to the coal mine underground drilling rig oil early warning monitoring device. The cooler conductive rod signal detection device includes two conductive rods installed at the hydraulic oil end of the cooler to collect the water in the hydraulic oil. Through the obtained resistivity signal; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com