Method for reducing external water pressure of deep-buried cross-sea shield segment of sandy soil stratum

A shield segment and water pressure technology, which is applied in the direction of earth drilling, drainage, underground chambers, etc., to achieve the effect of enhancing the arch effect of the soil, increasing the strength, and increasing the clearance of the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] The construction of the Qiongzhou Strait Tunnel faces many world-class problems and challenges: 1) The water pressure is above 2000kPa; 2) The diameter of the shield is more than 17m, which is unprecedented in the world; 3) The 300-meter-thick sand layer contains pebbles and gravel; 4) The tunnel is 27.6 kilometers long.

[0037] Since the current tunnel construction plan has not yet been determined, according to relevant data, the outer diameter of the segment ring is 16.7m, and the submarine stratum is mainly composed of silty fine sand, silty clay and clay.

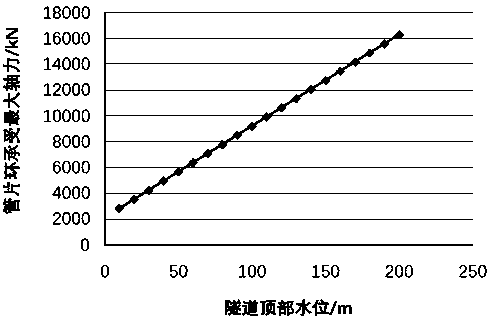

[0038] According to the modified customary method, the hoop axial force of the tunnel segment ring is obtained as figure 1 shown. According to the estimation of the design institute, under the action of 200m high water head pressure, the maximum hoop axial for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com