High-strength wrought aluminum alloy containing rare earth samarium and preparation method thereof

A technology for deforming aluminum alloys and aluminum alloys, which is applied in the field of metal materials and can solve problems such as poor mechanical properties of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

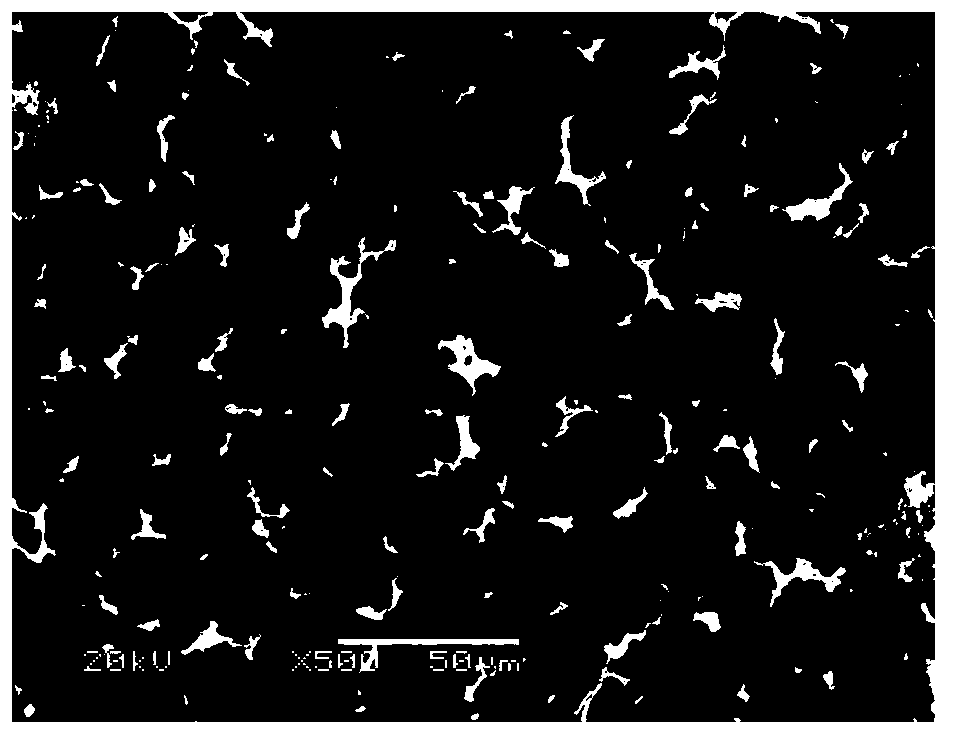

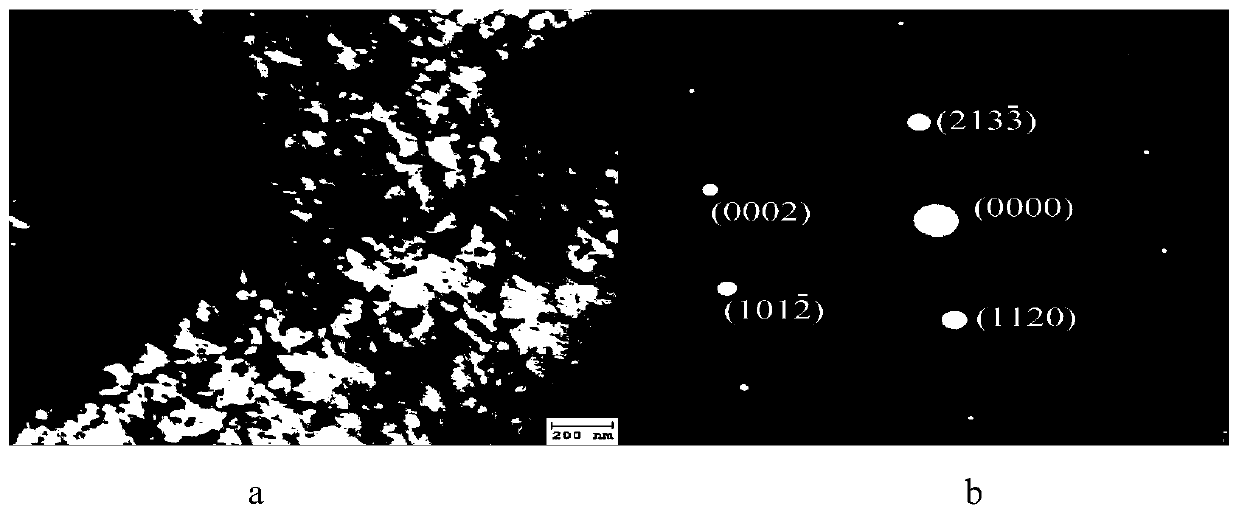

Image

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing a high-strength wrought aluminum alloy containing rare earth samarium. The aluminum alloy uses pure Al, Mg, Si and Al-30Cu, Al-25Sm intermediate alloys as raw materials for melting and casting, homogenization treatment, hot extrusion and Prepared by aging treatment, including the following steps:

[0024] (1) Aluminum alloy ingot preparation The raw material batching of pure Al, Mg, Si and Al-30Cu, Al-25Sm master alloy is cast into aluminum alloy ingot;

[0025] (2) Extrusion billet preparation: homogenize the aluminum alloy ingot at 520-560°C for 6-14 hours, and process it into an extrusion billet;

[0026] (3) Preparation of extrusion profiles: Preheat the above-mentioned extrusion billet and extrusion die in a resistance furnace at 470-500°C for 1-2h, and preheat the extruder at 400-500°C for 1-2h, and the extrusion ratio is 8 :1-20:1, the extrusion speed is 10-15m / min, and the extrusion profile is prepared ...

Embodiment 1

[0035] The high-strength deformed aluminum alloy of this embodiment is composed of the following components by mass percentage: Mg: 1.5wt.%, Si: 0.5wt.%, Cu: 0.2wt.%, Sm: 0.1wt.%, and the balance is Al and not Avoid impurities.

[0036] The preparation of the high-strength deformed aluminum alloy in this embodiment includes the following steps:

[0037] (1) Preparation of aluminum alloy ingots: raw materials of pure Al, Mg, Si and Al-30Cu, Al-25Sm intermediate alloys are dried according to the above mass percentage ingredients; the drying temperature is preferably 300 ° C, and the drying time is preferably 1h; put the dried pure Al ingot into a preheated 400-500°C crucible and heat up with the furnace until it is completely melted, and the temperature is controlled at 710°C to obtain molten aluminum; put the dried Mg, Si and Al- 30Cu, Al-25Sm master alloy is added to the molten aluminum, the temperature is controlled at 730°C, and the melt is stirred for 3 minutes after compl...

Embodiment 2

[0044] The difference between this embodiment 2 and embodiment 1 is that the mass percentage of the alloy components is Mg: 2.0wt.%, Si: 1.0wt.%, Cu: 0.5wt.%, Sm: 0.2wt.%, The balance is Al and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com