Printing ink connection material

A technology for linking materials and inks, applied in inks, household utensils, applications, etc., can solve problems such as printing quality, surface dryness, and slow drying speed that affect production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

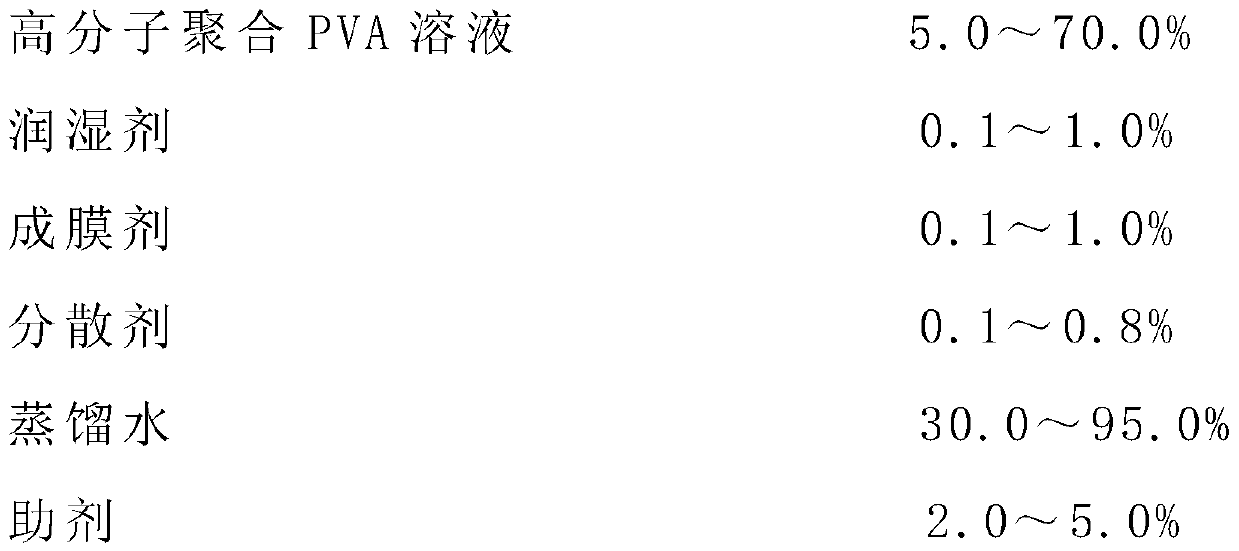

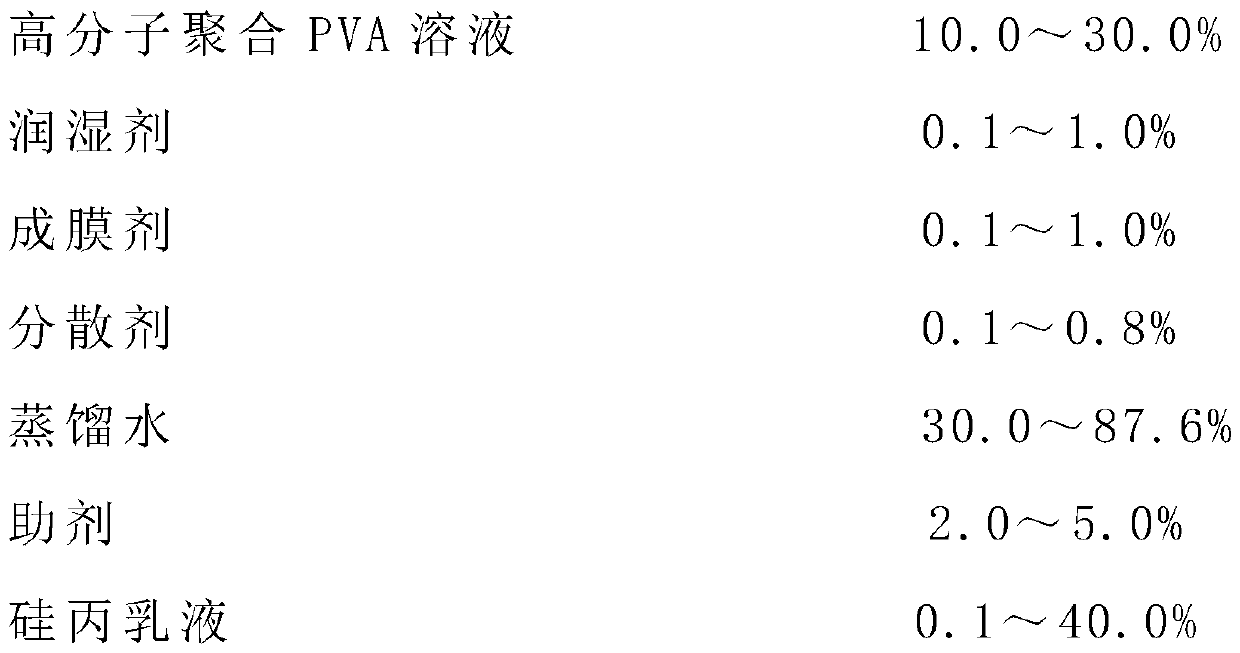

Method used

Image

Examples

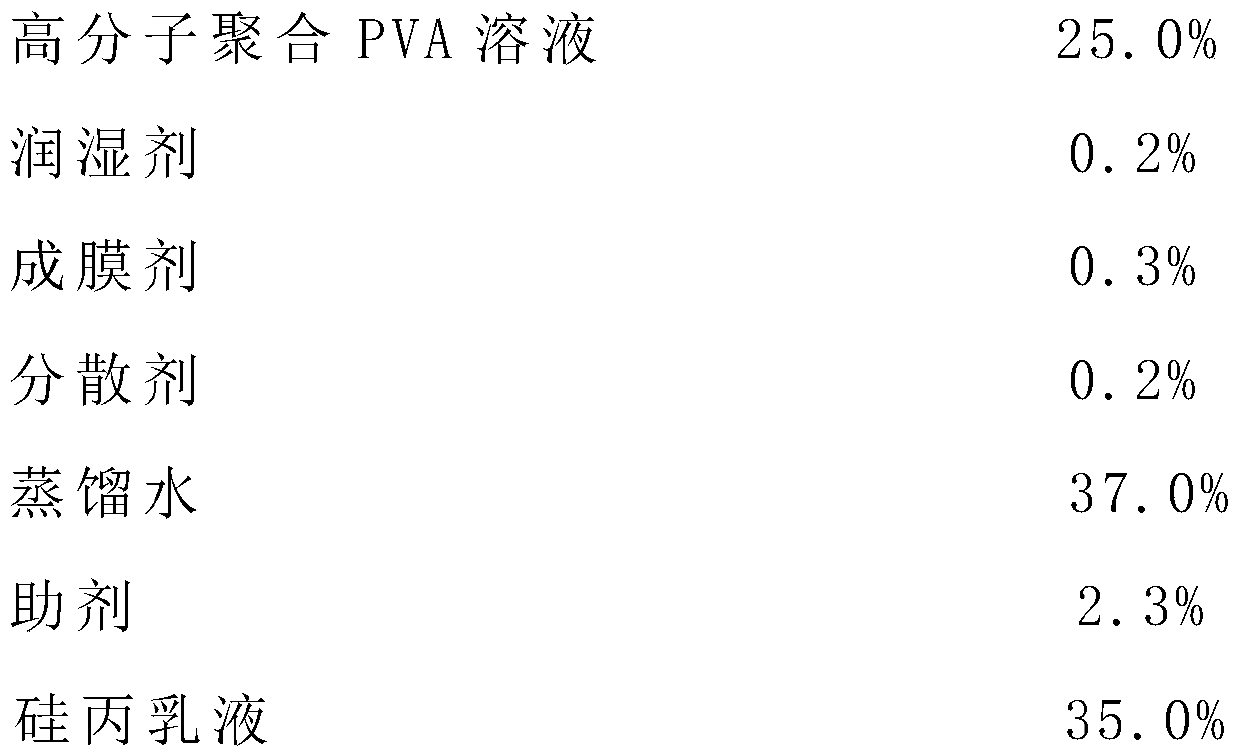

Embodiment 1

[0023] Preparation of ink vehicle for coated paper:

[0024] Step 1: Weigh 25.0 parts of polyvinyl alcohol 1799 and 37.0 parts of distilled water according to 100 parts by weight, and add 0.2 parts of wetting agent Dow 405 and film-forming agent alcohol ester at a speed of 400 to 700 rpm. Twelve 0.3 parts, leveling agent Glide411 0.5 parts, defoamer Foamex 830 0.2 parts, dispersed for 10 minutes;

[0025] Step 2: Add 35.0 parts of silicone acrylic emulsion and 1.0 parts of thickener at 600-1200 rpm; add 0.2 parts of dispersant Disprs610 at 1000-1300 rpm, and disperse for 20-30 minutes;

[0026] Step 3: Quality inspection sampling inspection fineness ≤ 50 microns; at 500-800 r / min speed, add 0.6 parts of surface treatment agent, after dispersing for 10 minutes, quality inspection sampling inspection; filter and pack after passing the test.

Embodiment 2

[0028] Preparation of ink vehicle for PVC film:

[0029] Step 1: Weigh 60.0 parts of Japanese Kuraray 32-80 and 37.0 parts of distilled water according to 100 parts by weight, and add 0.3 parts of wetting agent Dow Corning 5211 and film-forming agent U.S.A. Dow Dalpad C 95% DOW TPNB, DALPAD*C DALPAD*D DPM 0.2 parts in total, leveling agent Glide 411 0.4 parts, defoamer Foamex 8300.3 parts, disperse for 10 minutes;

[0030] Step 2: Add 0.8 parts of thickener at 600-1200 rpm; add 0.3 parts of dispersant Dispers 651 at 1000-1300 rpm, and disperse for 20-30 minutes;

[0031] Step 3: Quality inspection sampling inspection fineness ≤ 50 microns; at 500-800 rpm speed, put 0.7 parts of surface treatment agent, after dispersing for 10 minutes, quality inspection sampling inspection; filter and pack after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com